Likarolo tsa ho seha likarolo tsa faeba tse nepahetseng

Lesela/Khoele/Lik'hemik'hale tsa faeba Slitter/Li-blade tsa ho Seha

Likarolo tsa ho seha likarolo tsa faeba tse nepahetseng

Ho itšeha ha faeba ka lik'hemik'hale

Lehare la ho Seha la Dikarolo tse Sehang tsa Fiber Precision Slitter ke lehare le ikgethang le etseditsweng ho seha difaeba tsa maiketsetso, tse kang polyester, nylon, le difaeba tse ding tse entsweng ke motho.

Likhoele tsena li matla ebile li thata ho feta likhoele tsa tlhaho tse hlokang mahare a khethehileng ho netefatsa hore li petsoha hantle ebile li hloekile.

Lehare le letona le ka ntlafatsa bokgoni, la fokotsa ditshila le ho fokotsa kotsi ya tshenyo ya difaeba.

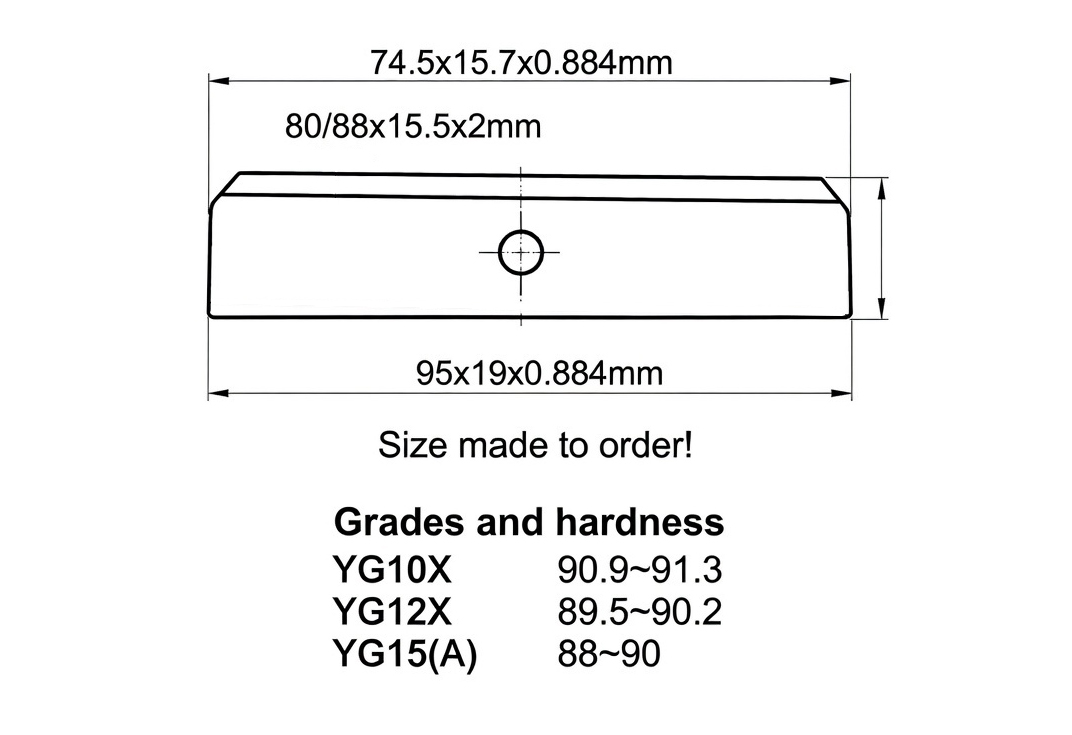

Boholo

Boholo ba dithipa tse tshesane tsa indasteri:

Ho iketsetsa lintho hoa tšehetsoa

Mokhoa oa ho khetha li-blades tsa ho seha tsa lik'hemik'hale?

Ho khetha mahare a faeba a Precision Slitter, lintlha tse latelang li lokela ho nahanoa.

1. Boitsebiso.

Lehare le lokela ho etsoa ka thepa e matla le e tšoarellang (joalo ka tungsten carbide), e tla hanela ho tsofala le ho lelefatsa bophelo ba lehare.

2. Sebopeho sa jeometri.

Moeli o bohale, o otlolohileng o tla dumella ho seha ho hlwekileng le ho nepahala. Moeli o lokela ho kgona ho mamella kgatello le kgatello ya ho seha ka hara difaeba tse thata.

3. ho phethela bokaholimo.

Ho ntlafatsa bokgoni ba ho sebetsa, bokaholimo bo boreleli le bo bentšitsoeng bo tla fokotsa khohlano le ho eketsa nako ea ho sebetsa ha lehare.

Lehare le lerootho le tla hlahisa mocheso o mongata nakong ea ts'ebetso ea ho seha, e leng se ka etsang hore likhoele li qhibilihe 'me li senyehe.

Kopo

Mokhoa oa tlhahiso ea lihlahisoa tsa fiber tsa lik'hemik'hale.

Ho bohlokoa ho seha likhoele tse tsoelang pele, likhoele tsa faeba ea lik'hemik'hale, liphutheloana tsa faeba kapa masela a faeba ea lik'hemik'hale ho latela bolelele kapa sebopeho se itseng.

Mohlala, ts'ebetsong e ka pele ea lesela la faeba ea lik'hemik'hale, khoele ea thepa e tala ea faeba ea lik'hemik'hale e phuthoa e sehoa ka likarolo tsa faeba tsa bolelele bo itseng ho latela litlhoko tsa tlhahiso bakeng sa ts'ebetso e latelang, joalo ka ho ohla, ho loha, jj.

Kaha thepa ea faeba ea lik'hemik'hale hangata e na le matla le ho tiea ho itseng, thipa e hloka ho khona ho seha kapele le ka mokhoa o hloekileng, kahoo lehare la thipa ea faeba ea lik'hemik'hale le siloa ka ho khetheha le ho sebetsoa ho netefatsa hore le na le ts'ebetso e ntle ea ho seha.

Melemo

Mekhoa ea tlhahlobo ea boleng ba ka tlung e netefatsa litlhoko tse tiileng tsa mamello;

Ho ikamahanya le maemo ho ikhethang libakeng tse fapaneng tsa ho seha,

Likoto tse nepahetseng haholo ntle le ho qhaqhoa;

Carbide e nyenyane e tiisa ho tšoarella le ho hanyetsa ho tsofala hantle;

Liphetoho tse fokolang tsa lehare li ntlafatsa tlhahiso;

HA HO na mafome le tšilafalo ea likhoele tsa lik'hemik'hale;

Maemo a tlase a litšila tsa thepa/likhechana.

Moetsi

Huaxin Cemented Carbide e shebane le tlhahiso ea mahare a tungsten carbide a entsoeng ka mokhoa o ikhethileng, ho kenyeletsoa meralo e tloaelehileng, lithipa tse tloaelehileng tse fetotsoeng, le litharollo tse ikhethileng ka botlalo. Ho tloha ho lokiseng phofo e tala ho isa ho sintering le ho sila ka nepo, ts'ebetso ea rona e kopaneng ea tlhahiso e re nolofalletsa ho fana ka lisebelisoa tsa carbide tse bōpehileng joaloka letlooa tse etselitsoeng mechine e itseng, thepa le maemo a ho seha ho pholletsa le liindasteri tse fapaneng.