Ha liindasteri li ntse li fetoha, tlhoko ea lisebelisoa tsa ho seha tse sebetsang hantle e ntse e tsoela pele ho hola, 'me mahare a tungsten carbide a etella pele. Blogeng ena, re hlahloba mekhoa ea mahare a tungsten carbide e bopang bokamoso ba mahare a indasteri, re sekaseka bakhanni ba bohlokoa ba' maraka, 'me re bolela esale pele menyetla ea kholo bakeng sa 2025 le ho feta. Ho tloha sefofaneng ho ea likoloing, tlhoko ea ho nepahala le ho tšoarella e khanna boqapi lefapheng lena.

Tlhoko e Holang ea 'Maraka: Liindasteri tsa Lifofane le Likoloi

Thelisebelisoa tsa ho seha tsa indasteri tsa lefats'e'Maraka o ntse o hola haholo, o matlafalitsoe ke liindasteri tse ntseng li hola tse kang tsa lifofane le tsa likoloi:

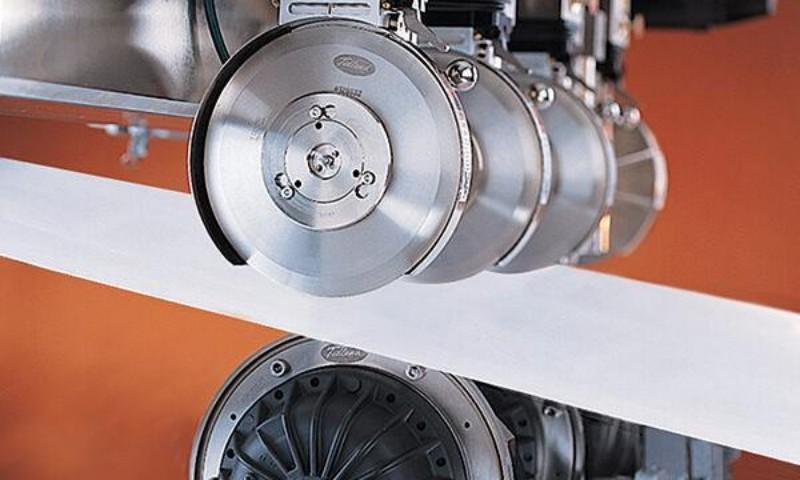

Sefofane:Lekala la lifofane le hloka lisebelisoa tsa ho seha ka nepo bakeng sa ho sebetsa thepa e bobebe, e matla joalo ka titanium le metsoako. Mahare a tungsten carbide, a tsebahalang ka ho thatafala ha ona le ho hanyetsa ho tsofala ha ona, a loketse lits'ebetso tsena. Kaha tlhahiso ea lefats'e ea lifofane e lebelletsoe ho eketseha ka 5% selemo le selemo, tlhoko ea mahare a tšoarellang e tla eketseha.

Likoloi:Ho fetohela ho dikoloi tsa motlakase (di-EV) le thepa e bobebe (mohlala, aluminium, faeba ya khabone) ho eketsa tlhoko ya ditharollo tse tswetseng pele tsa ho seha. Mahare a khabone ya tungsten a bohlokwa bakeng sa ho seha ka lebelo le phahameng, ka nepo tlhahisong ya dibeteri tsa EV le tlhahiso ya chassis, mme indasteri ya dikoloi e lebelletswe ho hola ka 4% ka 2025.

Liindasteri tsena li susumetsa mekhoa ea lehare la tungsten carbide, kaha bahlahisi ba batla lisebelisoa tse fanang ka bophelo bo bolelele, bokhoni bo phahameng le katleho ea litšenyehelo.

Lintlha tse Boletsweng esale pele tsa Kgolo bakeng sa Mahare a Tungsten Carbide

Mmaraka oa lehare la tungsten carbide o se o loketse ho atolosoa, ka bakhanni ba 'maloa ba bohlokoa ba kholo:

- Lintlha tsa Kholo ea 'Maraka:Litlaleho tsa indasteri li hakanya hore 'maraka oa lefats'e oa tungsten carbide blade o tla hola ka 6.5% ka 2025, o susumetsoa ke tlhoko ea lisebelisoa tse sa tsofaleng tsa ho sebetsa ka nepo. Kholo ena e matlafatsoa ke ho amoheloa ho eketsehileng ha litsamaiso tsa ho seha tse iketsang le tse potlakileng haholo.

- Tsoelo-pele ea Theknoloji:Mekhoa e mecha ea ho roala mahare (mohlala, khabone e kang taemane, TiN) e ntlafatsa ho tšoarella le ho fokotsa khohlano, e leng se etsang hore mahare a tungsten carbide a qothisane lehlokoa haholoanyane. Tsoelo-pele ena e tsamaellana le bokamoso ba mahare a indasteri, moo bokhoni le bophelo bo bolelele li leng tsa bohlokoa ka ho fetisisa.

- Limmaraka tse Ncha:Katoloso e potlakileng ea indasteri Asia-Pacific le Latin America e hlahisa menyetla e mecha. Mohlala, tlhahiso ea tlhahiso Chaena e lebelletsoe ho hola ka 7% ka 2025, e leng se eketsang tlhoko ea lisebelisoa tse tšepahalang tsa ho seha joalo ka makhasi a tungsten carbide.

Mekhoa ena e totobatsa monyetla o matla oa 'maraka bakeng sa li-blade tsa carbide tsa tungsten, haholo-holo makaleng a batloang haholo.

Tlhahiso e Tsitsitseng: Sehlooho se Chesang ho Ntlafatso ea Mahare

Ts'ebetso e tsitsitseng e bopa bokamoso ba mahare a indasteri, 'me mahare a tungsten carbide a ka pele ho phetoho ena:

- Thepa e Sireletsang Tikoloho: Carbide ea tungsten e ka sebelisoa hape, e lumellana le melao-motheo ea moruo o chitja. Bahlahisi ba ntse ba tsepamisa maikutlo haholoanyane mekhoeng ea tlhahiso e tsitsitseng, joalo ka ho fokotsa tšebeliso ea matla nakong ea tlhahiso ea mahare.

- Bophelo bo Atolositsoeng ba Sesebelisoa: Ho tšoarella ha mahare a tungsten carbide ho fokotsa makhetlo a ho nkeloa sebaka, ho fokotsa litšila le ho fokotsa tšusumetso ea tikoloho. Sena se tsamaisana le lipheo tsa tlhahiso e tsitsitseng, kaha liindasteri li ikemiselitse ho fokotsa tšebeliso ea mehloli.

- Bokgoni ba Matla: Liaparo tse tsoetseng pele le meralo e ntlafalitsoeng ea mahare li ntlafatsa bokhoni ba ho seha, li fokotsa tšebeliso ea matla lits'ebetsong tsa ho sebetsa. Sena se bohlokoa haholo bakeng sa liindasteri tse kang tsa lifofane, moo litšenyehelo tsa matla li leng kholo.

Ka ho amohela botsitso, di-blade tsa tungsten carbide ha di fihlelle ditlhoko tsa mmaraka feela empa di boetse di hohela bareki ba nang le tlhokomelo ya tikoloho, e leng se eketsang menyetla ya bona ya kgolo ka 2025.

Ke Hobane'ng ha U Lokela ho Tsetela ho Tungsten Carbide Blades Hona Joale?

Mekhoa ea lehare la tungsten carbide e supa bokamoso bo khanyang bakeng sa karolo ena ea lisebelisoa tsa ho seha. Ka tlhoko e ntseng e hola e tsoang liindastering tsa lifofane le likoloi, tsoelo-pele ea theknoloji, le ho tsepamisa maikutlo tlhahisong e tsitsitseng, lehare la tungsten carbide le behiloe ho busa 'maraka. Lintlha tsa indasteri tse tsoang litlalehong tsa tlhahiso li matlafatsa tebello ena, li bontša kholo e tsitsitseng lits'ebetsong tsa ho seha ka nepo.

Na o se o loketse ho dula o le ka pele ho tsela e nepahetseng? Ikopanye le rona bakeng sa tataiso ya ditsebi mabapi le ho kgetha di-blade tse nepahetseng bakeng sa ditlhoko tsa hao:

Email: lisa@hx-carbide.com

Webosaete:https://www.huaxincarbide.com

Mohala le WhatsApp: +86-18109062158

Fumana likeletso tse etselitsoeng uena ho ntlafatsa ts'ebetso ea hau ea ho seha le ho sebelisa monyetla oa tlhoko e ntseng e hola eamahare a tungsten carbide.

Nako ea poso: Hlakola-17-2025