Liindastering tse itšetlehileng ka ho seha ka nepo, nako e telele ea mahare a indasteri e ama ka kotloloho katleho le katleho ea litšenyehelo. Tlhokomelo e nepahetseng ea mahare a indasteri ha e fokotse feela nako ea ho sebetsa empa hape e eketsa bophelo ba sesebelisoa sa tungsten carbide, se tsejoang ka ho tšoarella ha sona ho ikhethang. Ho blog ena, re arolelana malebela a mahlano a sebetsang ho boloka mahare a hau a tungsten carbide a le boemong bo holimo, ho netefatsa ts'ebetso e tsitsitseng lits'ebetsong tse fapaneng.

1. Ho Hloekisa Kamehla Bakeng sa Tshebetso e Ntle

Litšila, lithōle le masalla a lintho tse bonahalang li ka bokellana holim'a mahare a indasteri nakong ea ts'ebetso ea ho seha, e leng se lebisang ho khohlanong le ho tsofala ho eketsehileng. Ho hloekisa khafetsa hoa hlokahala bakeng sa tlhokomelo ea mahare a indasteri:

- ▼Sebedisa borashe bo bonolo kapa moya o hatelletsoeng ho tlosa dikarolwana kamora ho sisinyeha ho hong le ho hong.

- ▼Bakeng sa masalla a manganga, sebedisa sehlahiswa se bobebe se tsamaellanang le tungsten carbide ho qoba ho senya bokahodimo ba lehare.

- ▼Qoba lisebelisoa tsa ho hloekisa tse khorofo tse ka ngoapang lehare, e leng se fokotsang bokgoni ba ho seha ha lona.

Ka ho boloka mahare a hloekile, o thibela ho tsofala pele ho nako mme o eketsa bophelo ba disebediswa tsa tungsten carbide, haholoholo bakeng sa mesebetsi e nepahetseng haholo.

2. Polokelo e Loketseng ho Thibela Tshenyo

Poloko e sa nepahalang e ka pepesetsa mahare mongobo, lerōleng, kapa likotsi tse sa lebelloang, e leng se behang botšepehi ba 'ona kotsing. Ho eketsa nako ea lisebelisoa tsa tungsten carbide:

- ▼Boloka di-blade sebakeng se omileng, se laolwang ke mocheso ho thibela ho bola.

- ▼Sebedisa mabokose a sireletsang kapa matsoho a mahare ho qoba ho taboha ha mathoko kapa ho ngoatheha ha bokaholimo.

- ▼Boloka di-blade di arohane le disebediswa tse ding ho thibela ho kopana le ho senyeha ka phoso.

Poloko e nepahetseng e netefatsa hore mahare a hao a tungsten carbide a lula a le bohale ebile a loketse ho sebelisoa, e leng se fokotsang litšenyehelo tsa ho a nkela sebaka.

3. Sebelisa Lehare le Nepahetseng bakeng sa Thepa

Mahare a tungsten carbide a tsebahala ka ho tšoarella ha ona, empa ho a sebelisa linthong tse sa lumellaneng ho ka khutsufatsa bophelo ba 'ona. Bakeng sa tlhokomelo e atlehang ea mahare a indasteri:

- ▼Tshwantsha lehare le thepa e sehwang (mohlala, tshepe, lehong, metsoako) ho qoba kgatello e feteletseng.

- ▼Netefatsa hore sebopeho sa lehlakore la lehare le ho koahela ha lona li loketse ts'ebeliso.

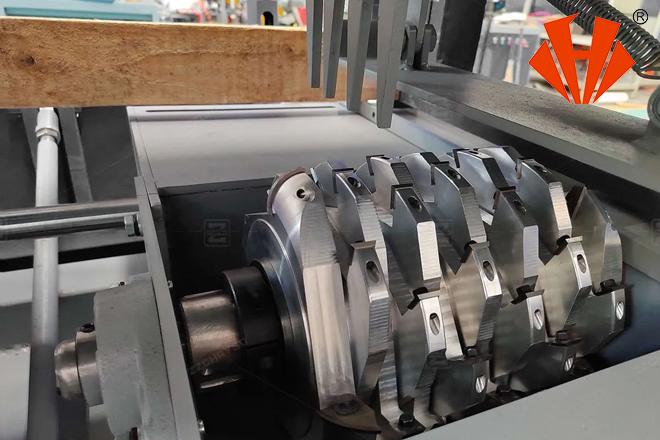

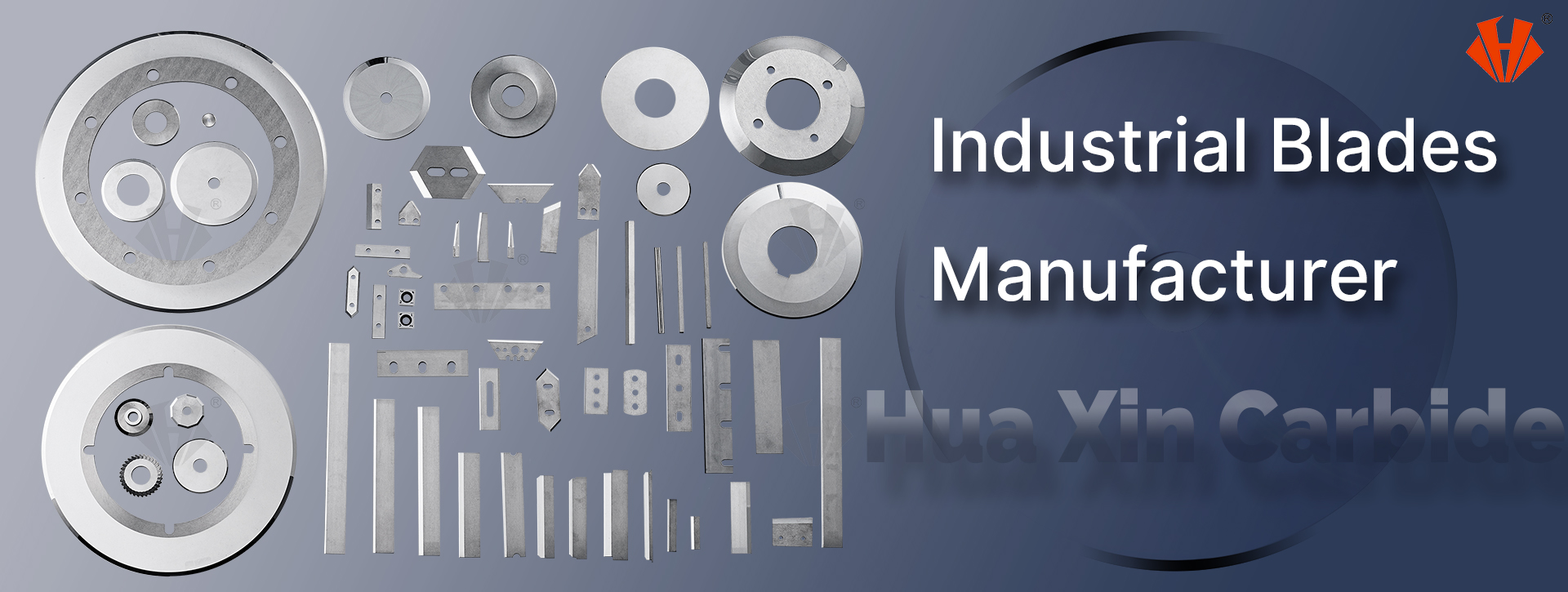

HUAXIN CARDINE E SIMENTITSOENGe fana ka lithipa le mahare a tungsten carbide a boleng bo holimo bakeng sa bareki ba rona ba tsoang liindastering tse fapaneng lefatšeng ka bophara. Mahare a ka hlophisoa ho lekana mechine e sebelisoang hoo e ka bang ts'ebelisong efe kapa efe ea indasteri. Lisebelisoa tsa lehare, bolelele ba lehlakore le liprofaele, mekhoa ea phekolo le lipente li ka fetoloa hore li sebelisoe le lisebelisoa tse ngata tsa indasteri, ho netefatsa ts'ebetso e ntle le bophelo bo bolelele.

4. Hlokomela ho Hloeka ha Lehare le ho le Lokisa Ha ho Hlokahala

Esita le mahare a tungsten carbide a tšoarellang a tla tsofala ha nako e ntse e ea. Tlhahlobo ea kamehla ke senotlolo sa tlhokomelo ea mahare a indasteri:

- ▼Hlahloba matšoao a ho tsofala, a kang ho fokotseha ha bokgoni ba ho seha kapa ho fifala ha mathoko ho bonahalang.

- ▼Loola di-blade o sebedisa disebediswa tse loketseng tsa ho sila tse etseditsweng carbide ya tungsten, o etse bonnete ba hore sebopeho sa ntlha ya ntlha se a bolokwa.

- ▼Qoba ho leotsa ho feta tekano, e leng se ka fokolisang sebopeho sa lehare.

Ka ho lokisa ho robeha ha sesebelisoa sa tungsten carbide esale pele, o ka eketsa bophelo ba sesebelisoa sa tungsten carbide mme wa boloka boleng ba ho seha bo tsitsitseng.

5. Kenya Ts'ebetsong Maemo a Tshebetso a Nepahetseng

Mocheso o feteletseng, lebelo, kapa khatello li ka potlakisa ho senyeha ha lehare, esita le bakeng sa mahare a tungsten carbide a tiileng. Ho sireletsa lisebelisoa tsa hau:

- ▼Sebetsa mechine ka lebelo le kgothaletswang le sekgahla sa ho fepa ho fokotsa ho bokellana ha mocheso.

- ▼Sebedisa sephodisang kapa setlolo se lekaneng ha o seha ho fokotsa kgohlano le kgatello ya mocheso.

- ▼Qoba ho jara lehare ka boima, e leng se ka bakang ho taboha kapa ho petsoha.

Mekhoa ena ha e ntlafatse tlhokomelo ea mahare a indasteri feela empa hape e sebelisa ho tšoarella ha tlhaho ha carbide ea tungsten, e fokotsa nako ea ho sebetsa le makhetlo a ho nkeloa sebaka.

Hobaneng o Lokela ho Khetha Li-blade tsa Tungsten Carbide?

Mahare a tungsten carbide ke khetho e ntle bakeng sa lits'ebetso tsa indasteri ka lebaka la ho thatafala ha ona ho ikhethang le ho hanyetsa ho tsofala. Ka ho latela malebela ana a tlhokomelo, o ka sebelisa monyetla o felletseng oa ho tšoarella ha ona, ho netefatsa ts'ebetso e theko e tlase le e tšepahalang. Hore na o seha tšepe, lehong, kapa metsoako, tlhokomelo e nepahetseng ke senotlolo sa ho atolosa bophelo ba sesebelisoa sa tungsten carbide.

Na u se u loketse ho ntlafatsa ts'ebetso ea hau ea ho seha? Ikopanye le rona bakeng sa tataiso ea litsebi mabapi le ho khetha mahare a nepahetseng bakeng sa litlhoko tsa hau:

- ▲Email: lisa@hx-carbide.com

- ▲Webosaete:https://www.huaxincarbide.com

- ▲Mohala le WhatsApp: +86-18109062158

Fumana likeletso tsa mahala tsa khetho ea lehare tse etselitsoeng indasteri ea hau 'me u qale ho ntlafatsa bophelo ba lisebelisoa tsa hau kajeno!

Ho tsetela tlhokomelong ea mahare a indasteri ke boiteko bo bonyenyane bo hlahisang phaello e kholo ea bokhoni le poloko ea litšenyehelo. Ka ho hloekisa, ho boloka le ho sebelisa mahare a hau a tungsten carbide ka nepo, o ka eketsa nako ea ona ea bophelo le ho boloka ts'ebetso e phahameng. Ka litharollo tsa boleng bo holimo tse tsoang ho HUAXIN CEMENTED CARBIDE, o hlomeletsoe ho sebetsana le phephetso efe kapa efe ea ho seha ka kholiseho.

Qala ho kenya tshebetsong malebela ana kajeno mme o bone phapang bophelong ba sesebediswa sa hao sa tungsten carbide!

Nako ea poso: Hlakola-21-2025