Lisebelisoa tsa carbide tse samentetsoeng li busa lisebelisoa tsa ho sebetsa tsa CNC. Linaheng tse ling, lisebelisoa tse fetang 90% tsa ho reteleha le lisebelisoa tse fetang 55% tsa ho sila li entsoe ka carbide e samentetsoeng. Ho feta moo, carbide e samentetsoeng e atisa ho sebelisoa ho etsa lisebelisoa tse akaretsang tse kang li-drill le li-cutter tsa ho sila sefahleho. Tšebeliso ea carbide e samentetsoeng e ntse e eketseha le lisebelisoa tse rarahaneng tse kang li-reamers, li-end mill, li-gear cutter tsa modulus tse mahareng le tse kholo bakeng sa ho sebetsa libaka tse thatafalitsoeng tsa meno, le li-broaches. Bokhoni ba ho seha ba lisebelisoa tsa carbide tse samentetsoeng bo makhetlo a 5 ho isa ho a 8 ho feta lisebelisoa tsa tšepe e lebelo le phahameng (HSS). Palo ea tšepe e tlosoang ka yuniti ea litaba tsa tungsten e ka ba makhetlo a 5 ho feta a HSS. Ka hona, ho sebelisa carbide e samentetsoeng haholo e le sesebelisoa ke e 'ngoe ea litsela tse sebetsang ka ho fetisisa tsa ho sebelisa mehloli ka katleho, ho ntlafatsa tlhahiso ea ho seha, le ho ntlafatsa melemo ea moruo.

Tlhophiso ea Lisebelisoa tsa Lisebelisoa tsa Carbide tse Sirelelitsoeng

Ho latela sebopeho sa lik'hemik'hale tse ka sehloohong, carbide e samentetsoeng e ka aroloa ka carbide e samentetsoeng e thehiloeng ho tungsten carbide le carbide e samentetsoeng e thehiloeng ho titanium carbonitride (Ti(C,N)), joalo ka ha ho bontšitsoe ho Tafole ea 3-1.

Carbide e entsoeng ka samente e thehiloeng ho Tungsten carbide e kenyelletsa:

Tungsten-cobalt (YG)

Tungsten-cobalt-titanium (YT)

Ka lik'habohaedreite tse sa tloaelehang tse ekelitsoeng (YW)

Mofuta o mong le o mong o na le melemo le mathata a wona. Di-carbide tse ekeditsweng di kenyeletsa tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), jj., mme cobalt (Co) ke yona karolo e sebediswang haholo ya ho kopanya tshepe.

Carbide e entsoeng ka samente e thehiloeng ho titanium carbonitride haholo-holo e na le TiC (e meng e nang le li-carbide tse ling kapa li-nitride tse ekelitsoeng), ka molybdenum (Mo) le nickel (Ni) e le mekhahlelo e sebelisoang haholo ea ho kopanya tšepe.

Ho latela boholo ba lijo-thollo, carbide e entsoeng ka samente e ka aroloa ka lihlopha tse latelang:

Carbide e tloaelehileng e entsoeng ka samente

Carbide e entsoeng ka samente e ntle

Carbide e entsoeng ka samente e nang le lithollo tse ngata

Ho ya ka GB/T 2075—2007, matshwao a ditlhaku ke ana a latelang:

HW: Carbide e sa koaheloang ka samente e nang le tungsten carbide (WC) e nang le boholo ba thollo ba ≥1μm

HF: Carbide e sa koaheloang ka samente e nang le tungsten carbide (WC) e nang le boholo ba lithollo tse ka tlase ho 1μm

HT: Carbide e sa koaheloang ka samente e nang le titanium carbide (TiC) kapa titanium nitride (TiN) kapa ka bobeli (e tsejoang hape e le cermet)

HC: Li-carbide tse samentetsoeng tse boletsoeng ka holimo tse nang le sekoahelo

Mokhatlo oa Machaba oa Maemo (ISO) o arola ho seha li-carbide tse entsoeng ka samente ka lihlopha tse tharo:

Sehlopha sa K (K10 ho isa ho K40):

E lekana le sehlopha sa YG sa Chaena (seo boholo ba sona se entsoeng ka WC-Co)

Sehlopha sa P (P01 ho isa ho P50):

E lekana le sehlopha sa YT sa Chaena (haholo-holo se entsoe ka WC-TiC-Co)

Sehlopha sa M (M10 ho isa ho M40):

E lekana le sehlopha sa YW sa Chaena (haholo-holo se entsoe ka WC-TiC-TaC(NbC)-Co)

Mekhahlelo ea sehlopha ka seng e emeloa ke nomoro e pakeng tsa 01 le 50, e bontšang letoto la li-alloy ho tloha ho thata ho fetisisa ho ea ho thata ho hoholo, bakeng sa khetho lits'ebetsong tse fapaneng tsa ho seha le maemo a ho sebetsa bakeng sa thepa e fapaneng ea mosebetsi. Haeba ho hlokahala, khoutu e mahareng e ka kenngoa pakeng tsa likhoutu tse peli tse haufi tsa ho arola, joalo ka P15 pakeng tsa P10 le P20, kapa K25 pakeng tsa K20 le K30, empa e se ke ea feta e le 'ngoe. Maemong a khethehileng, khoutu ea ho arola P01 e ka aroloa hape ka ho eketsa nomoro e 'ngoe e arotsoeng ke ntlha ea desimali, joalo ka P01.1, P01.2, jj., ho khetholla haholoanyane ho hanyetsa ho tsofala le ho tiea ha thepa bakeng sa ts'ebetso ea ho qeta.

Tshebetso ea Lisebelisoa tsa Lisebelisoa tsa Carbide tse samentetsoeng

1. Bothata Carbide e samentetsoeng e na le palo e kholo ea li-carbide tse thata (tse kang WC, TiC), e leng se etsang hore bothata ba eona bo be holimo haholo ho feta ba thepa ea tšepe e lebelo le phahameng. Ha bothata ba carbide e samentetsoeng bo le holimo, bo eketsa ho hanyetsa ha eona ho tsofala, e leng se atisang ho ba holimo haholo ho feta tšepe e lebelo le phahameng.

Ha karolo ea cobalt binder e le holimo, ho thatafala ha motsoako hoa fokotseha.

Kaha TiC e thata ho feta WC, metsoako ea WC-TiC-Co e na le bothata bo phahameng ho feta metsoako ea WC-Co. Ha TiC e le ngata, bothata bo ba matla le ho feta.

Ho eketsa TaC ho di-alloy tsa WC-Co ho eketsa thatafalo ka hoo e ka bang 40 ho isa ho 100 HV; ho eketsa NbC ho e eketsa ka 70 ho isa ho 150 HV.

2. MatlaMatla a kobehang a khabide e samentetsweng a ka ba karolo ea boraro ho isa ho halofo feela ea thepa ea tšepe e lebelo le phahameng.

Ha cobalt e le ngata, matla a motsoako ona a eketseha.

Li-alloy tse nang le TiC li na le matla a tlase ho feta tse se nang TiC; ha TiC e le ngata, matla a eona a tlaase.

Ho eketsa TaC ho WC-TiC-Co carbide e samentetsoeng ho eketsa matla a yona a ho kobeha mme ho eketsa haholo ho hanyetsa ha bohale ba morao-rao ho kgaoha le ho robeha. Ha dikahare tsa TaC di ntse di eketseha, matla a mokhathala le ona a a ntlafala.

Matla a khatello a khabide e samentetsoeng a phahame ka 30% ho isa ho 50% ho feta a tšepe e lebelo le phahameng.

3. Ho tieaBothata ba khabide e samentetsoeng bo tlase haholo ho feta ba tšepe e lebelo le phahameng.

Li-alloy tse nang le TiC li na le matla a tlase ho feta tse se nang TiC; ha litaba tsa TiC li ntse li eketseha, matla a tsona aa fokotseha.

Ho di-alloy tsa WC-TiC-Co, ho eketsa tekanyo e loketseng ya TaC ho ka eketsa ho tiea ka hoo e ka bang 10% ha ho ntse ho bolokwa ho hanyetsa mocheso le ho hanyetsa ho tsofala.

Ka lebaka la ho tiea ha eona ho tlase, carbide e samentetsoeng ha e lokele maemo a nang le litlamorao tse matla kapa ho thothomela, haholo-holo ka lebelo le tlase la ho seha moo ho khomarela le ho qhaqha ho leng matla haholo.

4. Thepa ea 'Mele ea Thempereichara Ho tsamaisoa ha mocheso ha carbide e samentetsoeng ho phahame ka makhetlo a ka bang 2 ho isa ho a 3 ho feta ha tšepe e lebelo le phahameng.

Kaha phetiso ea mocheso ea TiC e tlase ho feta ea WC, li-alloy tsa WC-TiC-Co li na le phetiso ea mocheso e tlase ho feta li-alloy tsa WC-Co. Ha TiC e le ngata, phetiso ea mocheso e fokola haholo.

5. Khanyetso ea Mocheso Carbide e samentetsoeng e na le khanyetso e phahameng haholo ea mocheso ho feta tšepe e lebelo le phahameng 'me e ka seha ka 800 ho isa ho 1000°C ka khanyetso e ntle khahlanong le ho fetoha ha polasetiki mochesong o phahameng.

Ho eketsa TiC ho eketsa thatafalo ya mocheso o phahameng. Kaha mocheso o nolofatsang wa TiC o phahame ho feta wa WC, thatafalo ya di-alloy tsa WC-TiC-Co e fokotseha butle ka mocheso ho feta di-alloy tsa WC-Co. Ha TiC e le ngata mme cobalt e le nyane, phokotseho e ba nyane.

Ho eketsa TaC kapa NbC (ka mocheso o phahameng oa ho nolofatsa ho feta TiC) ho eketsa thata le matla a mocheso o phahameng.

6. Litšobotsi tsa ho Khahlanong le ho KhomarelaMocheso oa ho khomarela oa carbide e samentetsoeng o phahame ho feta oa tšepe e lebelo le phahameng, e leng se e fang khanyetso e betere khahlanong le ho tsofala ha ho khomarela.

Mocheso oa ho khomarela oa Cobalt ka tšepe o tlase haholo ho feta oa WC; ha litaba tsa cobalt li ntse li eketseha, mocheso oa ho khomarela oa fokotseha.

Mocheso oa ho khomarela oa TiC o phahame ho feta oa WC, kahoo li-alloy tsa WC-TiC-Co li na le mocheso o phahameng oa ho khomarela (o ka bang 100°C ho feta) ho feta li-alloy tsa WC-Co. TiO2 e entsoeng mochesong o phahameng nakong ea ho seha e fokotsa ho khomarela.

TaC le NbC li na le mocheso o phahameng oa ho khomarela ho feta TiC, e leng se ntlafatsang thepa ea ho thibela ho khomarela. Kamano ea TaC le thepa ea mosebetsi e nyane haholo ho feta karolo ea leshome ea WC.

7. Ho Tsitsisa Lik'hemik'haleHo hanyetsa ho tsofala ha lisebelisoa tsa carbide tse samentetsoeng ho amana haufi-ufi le botsitso ba tsona ba 'mele le ba lik'hemik'hale mochesong o sebetsang.

Mocheso oa oxidation oa carbide e samentetsoeng o phahame ho feta oa tšepe e lebelo le phahameng.

Mocheso oa oxidation oa TiC o phahame haholo ho feta oa WC, kahoo li-alloy tsa WC-TiC-Co li fumana boima bo fokolang ba oxidation mochesong o phahameng ho feta li-alloy tsa WC-Co; ha TiC e le ngata, khanyetso ea oxidation e ba matla le ho feta.

Mocheso oa oxidation oa TaC le oona o phahame ho feta oa WC, 'me metsoako e kopantsoeng e nang le TaC le NbC e ntlafalitse khanyetso ea oxidation ea mocheso o phahameng. Leha ho le joalo, tekanyo e phahameng ea cobalt e etsa hore oxidation e be bonolo.

Hobaneng o lokela ho kgetha Chengduhuaxin Carbide?

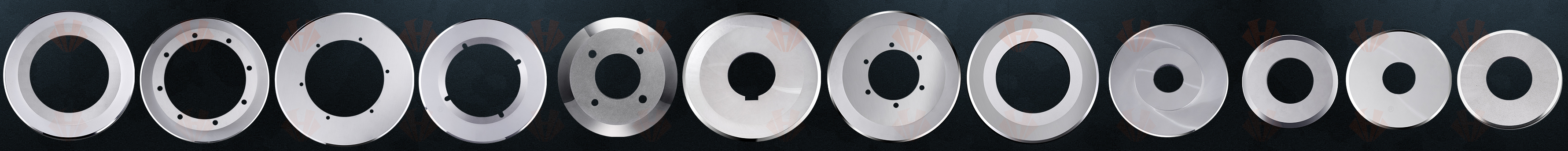

Chengduhuaxin Carbide e hlahella 'marakeng ka lebaka la boitlamo ba eona ba boleng le boqapi. Mahare a bona a k'hapete ea tungsten carbide le mahare a nang le tungsten carbide a entsoe bakeng sa ts'ebetso e phahameng, a fa basebelisi lisebelisoa tse fanang ka ho seha ho hloekileng le ho nepahala ha ts'ebeliso e boima ea indasteri. Ka ho tsepamisa maikutlo ho tšoarelleng le ho sebetsa hantle, mahare a nang le likheo a Chengduhuaxin Carbide a fana ka tharollo e phethahetseng bakeng sa liindasteri tse hlokang lisebelisoa tse tšepahalang tsa ho seha.

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oalihlahisoa tsa tungsten carbide,tse kang lithipa tsa ho kenya carbide bakeng sa ho betla lehong, carbidelithipa tse chitjabakeng saho phunya lithupa tsa sefe sa koae le sakerete, lithipa tse chitja bakeng sa ho petsoha ha khateboto e nang le korugate,mahare a lehare a masoba a mararo/mahare a nang le dikotwana bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a sehang faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Phupu-23-2025