Mahare a tungsten carbide a sebelisoa haholo indastering ea khateboto e kobehileng ka lebaka la ho thatafala ha ona le ho hanyetsa ho tsofala. Leha ho le joalo, nakong ea ts'ebetso ea ho seha, mahare ana a ntse a ka senyeha, e leng se lebisang ho fokotseng ts'ebetso, keketseho ea nako ea ho se sebetse, le litšenyehelo tse phahameng tsa ts'ebetso. Ho utloisisa lisosa tse tloaelehileng tsa tšenyo ea mahare le ho kenya tšebetsong lintlafatso tse reriloeng ho bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea ho seha. Ka tlase, ke hlalosa mabaka a mantlha a tšenyo ea mahare le maano a tsamaellanang a ntlafatso ea mahare.

Mabaka a Tšenyo ea Lehare la Tungsten Carbide Slitting

●Ho roala ka thata

Khateboto e nang le masenke, haholo-holo ha e entsoe ka likhoele tse sebelisitsoeng hape kapa e nang le diminerale (mohlala, li-filler kapa li-coat), e ka ba e khopisang haholo. Ho khopisa hona ho etsa hore lehlakore la lehare le senyehe ha nako e ntse e ea, e leng se lebisang ho fifaleng le ho fokotseng bokhoni ba ho seha.

●Ho haha ho khomarela

Likhomaretsi tse sebelisoang ho lamination ea likarolo tsa khateboto tse kobehileng li ka khomarela lehare nakong ea ho seha. Ho bokellana hona ho ama ho hlaka ha lehare, ho eketsa khohlano, 'me ho ka etsa hore lehare le chese haholo kapa le be le robehe tlas'a khatello.

●Ho kenya Lehare le sa Lokang

Haeba lehare le sa otloloha hantle kapa le sa kenngwa ka thata mochining o tabolang, le ka senyeha ka ho se leka-lekane kapa la robeha ka tshohanyetso. Ho se lokisoe hantle ho ka boela ha lebisa ho thothomeleng ho feteletseng, e leng se eketsang tshenyo e eketsehileng.

●Matla a ho Seha a Feteletseng

Ho sebelisa matla a mangata haholo nakong ea ts'ebetso ea ho petsoha, haholo-holo ha ho sehoa khateboto e teteaneng kapa e thata, ho ka etsa hore lehare le petsohe kapa le petsohe. Sena se baka mathata haholo haeba lehare le kopana le liphetoho tse sa lebelloang tsa thepa, joalo ka mafito kapa libaka tse teteaneng khatebotong.

●Mofuthu oa ho Hlahisa

Khohlano pakeng tsa lehare le khateboto e hlahisa mocheso, e leng se ka nolofatsang thepa ea carbide ea tungsten, e leng se lebisang ho tsofaleng pele ho nako, ho feto-fetoha ha lintho, kapa esita le ho petsoha ha mocheso. Mocheso o feteletseng o boetse o mpefatsa ho bokellana ha sekhomaretsi.

●Ho se lekane ha thepa

Liphetoho botenya, ho teteana, kapa sebopeho sa khateboto (mohlala, mongobo kapa tataiso ea faeba) li ka baka khatello e sa lebelloang lehareng. Ho se tsitse hona ho ka etsa hore lehare le be le litlamorao tsa tšohanyetso kapa mojaro o sa lekanang, e leng se lebisang ho petsoheng kapa ho robeheng.

Maano a Ntlafatso ea Mahare

Ho rarolla mathata a boletsoeng ka holimo le ho ntlafatsa ho tšoarella le ts'ebetso ea mahare a tungsten carbide, maano a latelang a ka sebelisoa:

●●● Ntlafatso ea Lintho

Sebelisa carbide ea tungsten ea boemo bo holimo e nang le meaho e metle ea lithollo kapa u kenye lintho tse ling tse tlatsetsang (mohlala, li-binder tsa cobalt kapa li-carbide tse ling) ho eketsa ho thatafala ha lehare, ho tiea le ho hanyetsa ho tsofala ha lona. Sena se thusa lehare ho mamella ho tsofala ho matla le ho fokotsa makhetlo a ho leotsa kapa ho nkeloa sebaka.

●●●Theknoloji ea ho Koahela

Kenya dikobo tse tsoetseng pele tse kang Titanium Nitride (TiN), Titanium Carbonitride (TiCN), kapa Diamond-Like Carbon (DLC) bokaholimong ba lehare. Dikobo tsena di fokotsa kgohlano, di ntlafatsa ho hanyetsa ho tsofala, mme di thibela ho bokellana ha sekhomaretsi ka ho etsa bokaholimo bo boreleli, bo thata bo hanelang ho kgomarela le ho kgohlahala.

●●● Ntlafatso ea Geometry ea Edge

Lokisetsa sebopeho sa ntlha ya lehare ho latela dibopeho tse ikgethang tsa khateboto e kobehileng. Mohlala:

Moeli o bohale (mohlala, o nang le radius e nyane ea moeli) o ka fana ka maqeba a hloekileng le ho fokotsa ho taboha.

Moeli o chitja kapa o leolitsoeng hanyane o ka aba matla a ho seha ka ho lekana haholoanyane, e leng se fokotsang kotsi ea ho qhaqha ha ho kopana le ho se lumellane ha thepa.

Ho phaella moo, ho ntlafatsa sekhutlo le boemo ba lehare ho ka ntlafatsa bokgoni ba lona ba ho sebetsana le sebopeho se nang le leqhubu sa khateboto e kobehileng ntle le ho tshwarwa.

●●●Ho qhala ha mocheso

Ntlafatsa moralo oa lehare ho ntlafatsa ho qhalana ha mocheso nakong ea ho seha. Sena se ka finyelloa ka:

Ho kenyelletsa likanale tse pholisang kapa ho sebelisa thepa ea lehare e nang le conductivity e betere ea mocheso.

Ho rala lehare ka sebaka se seholo sa bokaholimo kapa li-heat sinks ho qhala mocheso ka katleho.

Ho fokotsa ho bokellana ha mocheso ho thusa ho boloka lehare le tiile ebile ho thibela tshenyo ya mocheso.

●●●Taolo ea Boleng

Kenya tshebetsong mehato e thata ya taolo ya boleng nakong ya tshebetso ya tlhahiso ho netefatsa hore lehare le na le botsitso, jwalo ka ho thatafala, ho hlaka ha lehlakore, le ho nepahala ha boholo. Sena se fokotsa monyetla wa diphoso tse ka lebisang ho hloleheng pele ho nako.

●●● Thuto le Tlhokomelo ea Basebelisi

Fana ka litataiso tse felletseng le koetliso bakeng sa ho kenya lehare hantle, ho lekalekanya le tlhokomelo. Ho ruta basebetsi ka liparamente tse nepahetseng tsa ho seha (mohlala, lebelo, matla le setlolo) ho ka fokotsa liphoso tsa batho le ho thibela tšenyo e bakoang ke ho se sebetse hantle.

Mahare a tungsten carbide a sehiloeng a sebelisoang ho seheng khateboto e kobehileng a ka senyeha ka lebaka la ho tsofala ho matla, ho bokellana ha sekhomaretsi, ho kenngoa ho sa lokelang, matla a ho seha a feteletseng, tlhahiso ea mocheso le ho se lumellane ha thepa. Ho fokotsa mathata ana, ntlafatso ea mahare e lokela ho tsepamisa maikutlo ho ntlafatseng ho hanyetsa ho tsofala ha thepa, ho sebelisa lipeipi tse fokotsang khohlano, ho ntlafatsa jiometri ea bohale, ho ntlafatsa ho qhalana ha mocheso, le ho netefatsa taolo e tiileng ea boleng. Ho feta moo, ho ruta basebelisi ka ho sebetsana le mahare le tlhokomelo e nepahetseng ho bohlokoa bakeng sa ho atolosa bophelo ba mahare le ho boloka bokhoni ba ho seha. Ka ho kenya tšebetsong maano ana, bahlahisi ba ka fokotsa tšenyo ea mahare haholo, ba ntlafatsa ts'epo ea ts'ebetso, le ho fokotsa litšenyehelo tsa tlhahiso ka kakaretso.

Hobaneng o lokela ho kgetha Chengduhuaxin Carbide?

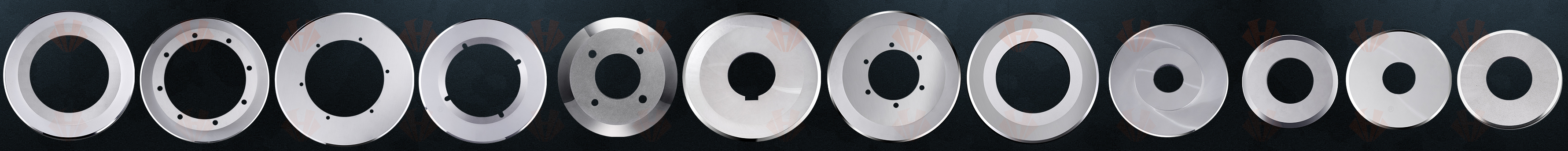

Chengduhuaxin Carbide e hlahella 'marakeng ka lebaka la boitlamo ba eona ba boleng le boqapi. Mahare a bona a k'hapete ea tungsten carbide le mahare a nang le tungsten carbide a entsoe bakeng sa ts'ebetso e phahameng, a fa basebelisi lisebelisoa tse fanang ka ho seha ho hloekileng le ho nepahala ha ts'ebeliso e boima ea indasteri. Ka ho tsepamisa maikutlo ho tšoarelleng le ho sebetsa hantle, mahare a nang le likheo a Chengduhuaxin Carbide a fana ka tharollo e phethahetseng bakeng sa liindasteri tse hlokang lisebelisoa tse tšepahalang tsa ho seha.

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oalihlahisoa tsa tungsten carbide,tse kang lithipa tsa ho kenya carbide bakeng sa ho betla lehong, carbidelithipa tse chitjabakeng saho phunya lithupa tsa sefe sa koae le sakerete, lithipa tse chitja bakeng sa ho petsoha ha khateboto e nang le korugate,mahare a lehare a masoba a mararo/mahare a nang le dikotwana bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a sehang faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Phuptjane-18-2025