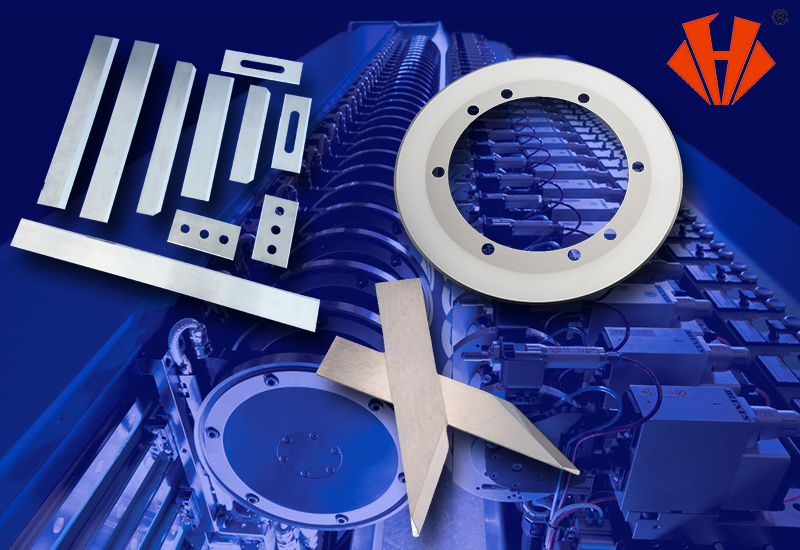

Mefuta ea Li-blade tsa Tungsten Carbide Litšebelisong tsa Liindasteri

Mahare a tungsten carbide ke karolo ea bohlokoa liindastering tse fapaneng, tse tsejoang ka ho tšoarella ha tsona, ho ba thata le ho hanyetsa ho tsofala. Mahare ana a sebetsang hantle a sebelisoa haholo lits'ebetsong tsa ho seha, ho sila le ho sebetsa ka mechine, moo ho nepahala le ho phela nako e telele li leng bohlokoa. Ha liindasteri li ntse li tsoela pele ho batla ts'ebetso e betere le bokgabane, mahare a tungsten carbide a hlahile e le thepa e khethiloeng ka lebaka la thepa ea ona e ikhethang. Sehloohong sena, re tla hlahloba mefuta e fapaneng ea mahare a tungsten carbide a sebelisoang hangata lits'ebetsong tsa indasteri.

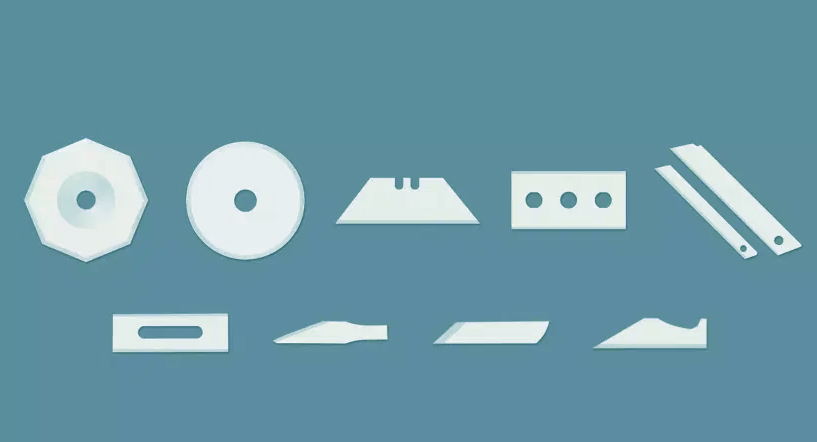

1. E tloaelehilengLi-blades tsa Tungsten Carbide

Mofuta o tloaelehileng haholo oa makhasi a tungsten carbide ke makhasi a tloaelehileng, a atisang ho sebelisoa lits'ebetsong tse akaretsang tsa ho seha. Makhasi ana a tsebahala ka ho thatafala ha 'ona le bokhoni ba 'ona ba ho seha mefuta e mengata ea thepa, ho kenyeletsoa le litšepe, polasetiki le metsoako. Makhasi a tloaelehileng a tungsten carbide hangata a fumanoa lisakeng, lisehing le lisebelisoa tse potolohang. Ho hanyetsa ha 'ona ho hoholo khahlanong le ho tsofala le ho bola ho etsa hore a be a loketseng liindasteri tse kang tlhahiso, kaho le merafo.

2. Kenya Mahare a Tungsten Carbide

Mahare a kenyang ke mofuta oa lehare la tungsten carbide le etselitsoeng ho kenngoa ka har'a li-tool holder kapa mechine. Mahare ana a atisa ho sebelisoa lits'ebetsong tsa ho reteleha, ho sila le ho sebetsa ka tšepe, haholo-holo indastering ea ts'ebetso ea tšepe. Mahare a kenyang a na le mekhoa e mengata haholo, kaha a ka nkeloa sebaka ntle le tlhoko ea ho nkela sesebelisoa sohle sebaka, a fana ka tharollo e theko e tlaase bakeng sa ts'ebetso e hlokang liphetoho tse ngata tsa lehare. Mahare a tungsten carbide a kenyang a fumaneha ka mefuta e fapaneng ea libopeho, ho kenyeletsoa le sekwere, chitja le khutlotharo, ho latela ts'ebeliso e itseng ea ho seha.

3. Mahare a Carbide a samentetsoeng

Mahare a carbide a samente a entsoe ka likaroloana tsa carbide tsa tungsten tse kopantsoeng hammoho le sehokelo sa tšepe, hangata cobalt. Mahare ana a etselitsoe mesebetsi ea ho seha e sebetsang hantle 'me a fana ka ho boloka bohale bo phahameng le ho hanyetsa ho tsofala. Mahare a carbide a samente a atisa ho sebelisoa liindastering moo ho hlokahalang ho nepahala ho hoholo le bophelo bo bolelele ba lisebelisoa, joalo ka mafapha a lifofane, likoloi le tlhahiso. Mahare ana a sebetsa hantle haholo ho seheng thepa e thata joalo ka tšepe, aluminium, esita le titanium.

4. Mahare a koahetsoeng ka khabone

Mahare a koahetsoeng ka khabide hangata a etsoa ka tšepe kapa thepa e 'ngoe ea motheo 'me a koahetsoe ka lera le lesesaane la khabide ea tungsten. Seaparo sena se ntlafatsa ho hanyetsa ho tsofala ha lehare, ho thatafala le ts'ebetso ka kakaretso, e leng se etsang hore e be a loketseng lits'ebetso tse boima. Mahare ana a sebelisoa hangata liindastering tse kang ts'ebetso ea lijo, ho sebetsa ka lehong le tlhahiso ea pampiri, moo ho sehiloeng le ho tšoarella ha boleng bo holimo ho leng bohlokoa. Mahare a koahetsoeng ka khabide le 'ona a tumme ho seheng lisebelisoa bakeng sa liindasteri tsa likoloi le tsa lifofane ka lebaka la bokhoni ba tsona ba ho mamella mocheso o phahameng le likhatello.

Mahare a tungsten carbide a bapala karolo ea bohlokoa lits'ebetsong tsa indasteri tse hlokang ho tšoarella, ho nepahala le ho phela nako e telele. Ho tloha mahare a tloaelehileng ho isa ho mefuta ea carbide e kenngoang le e samenteang, mahare ana a fana ka litharollo tse etselitsoeng mafapha a fapaneng, ho kenyeletsoa tlhahiso, likoloi, lifofane, le tse ling. Ha liindasteri li ntse li tsoela pele ho fetoha 'me li batla lisebelisoa tse sebetsang hantle haholoanyane, mahare a tungsten carbide a tla lula e le lejoe la motheo la mahlale a ho seha a sebetsang hantle.

Huaxin Samente Carbide (https://www.huaxincarbide.com)Khamphani, e leng kgwebo ya naha ya theknoloji e phahameng e ikgethileng dipatlisisong, ntshetsopeleng, tlhahisong le thekisong ya dithipa le mahare a diindasteri a carbide a samentetsweng ka dilemo tse fetang 20, ke Mofani wa hao wa Tharollo ya Thipa ya Mochini wa Diindasteri.

Nako ea poso: Tshitwe-05-2024