Li-blade tsa carbide li etsoa joang?

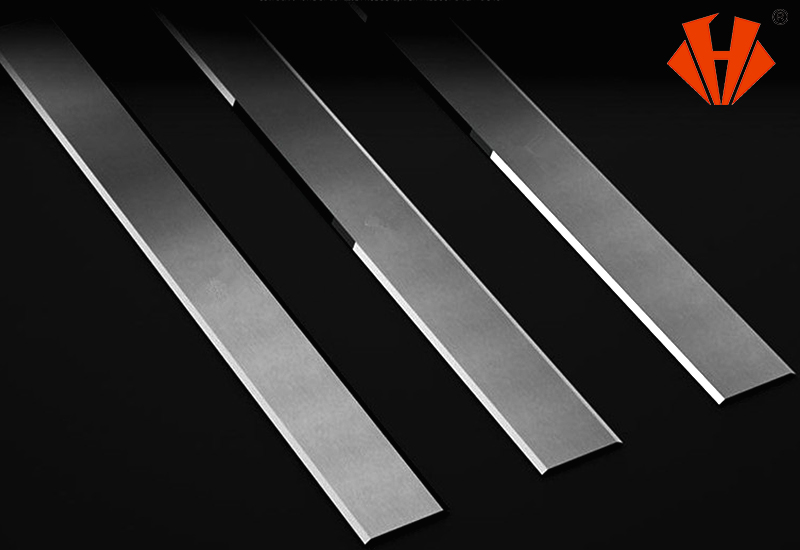

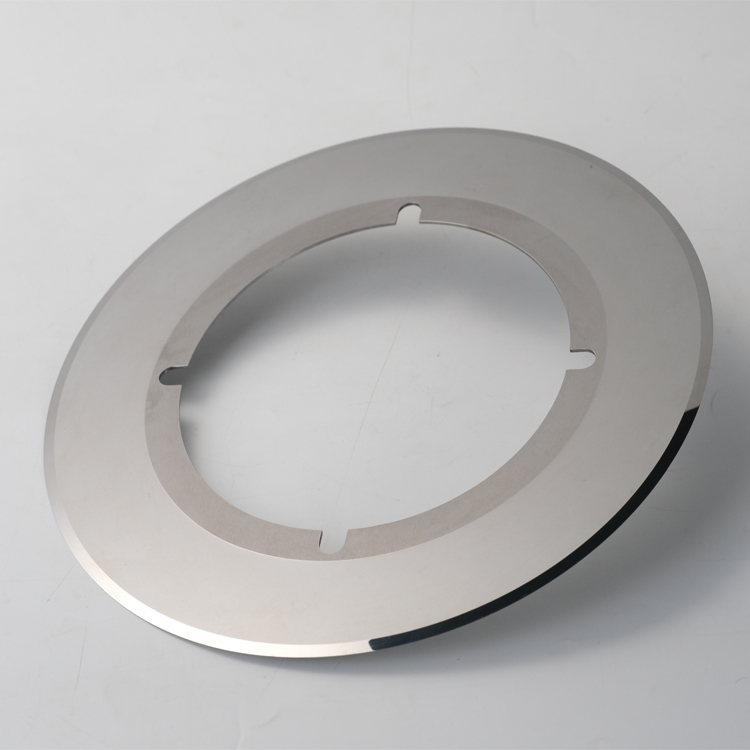

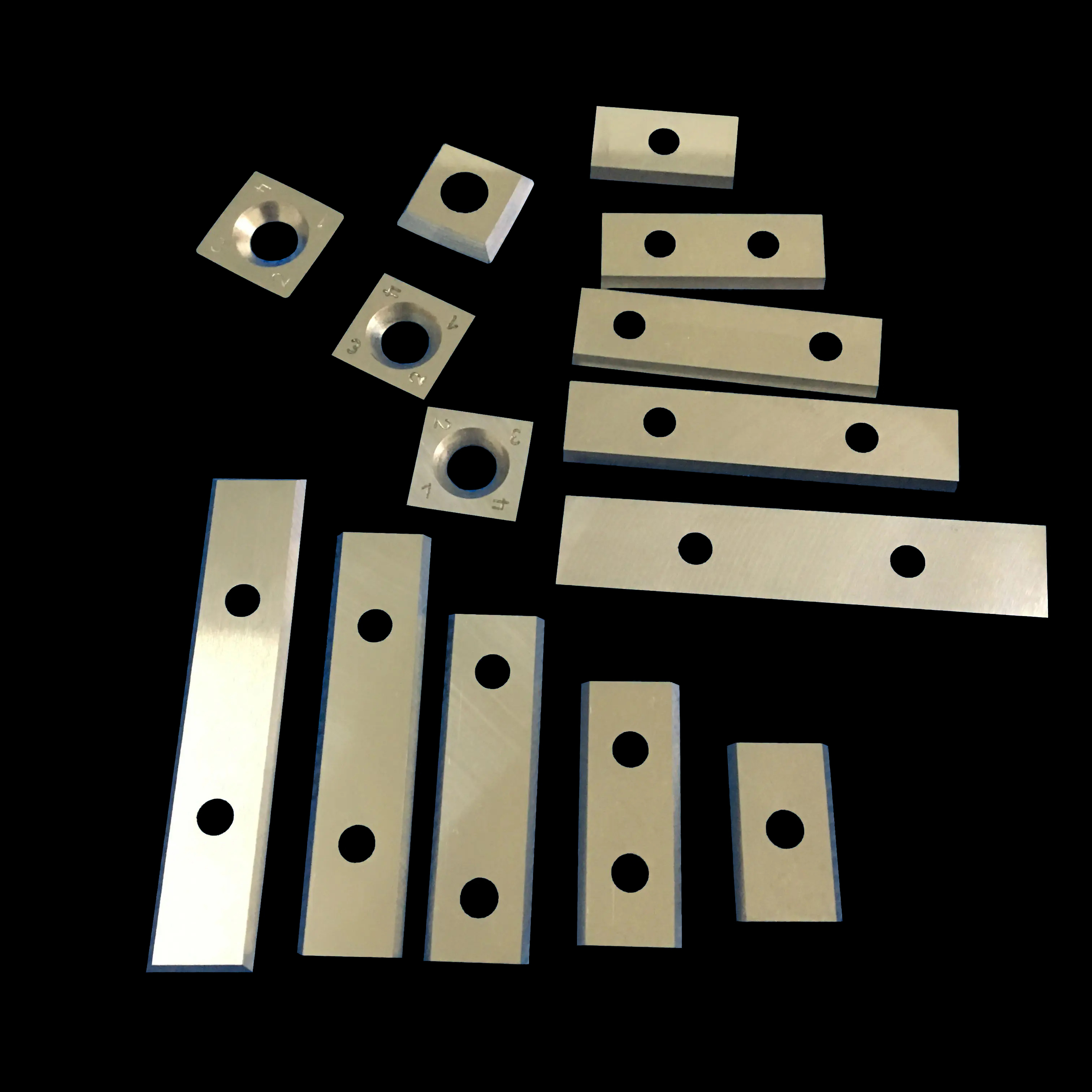

Mahare a khabide a nkoa e le a bohlokoa ka lebaka la ho thatafala ha ona ho ikhethang, ho se tsofale, le bokhoni ba ho boloka bohale ka nako e telele, e leng se etsang hore e be a loketseng ho seha thepa e thata.

Mahare a khabide hangata a etsoa ka mokhoa o kenyeletsang ho sila phofo ea khabide ea tungsten hore e be sebopeho se tiileng, e lateloe ke ho bopa le ho qeta lehare. Mona ke kakaretso ea mohato ka mohato ea kamoo mahare a khabide a hlahisoang ka kakaretso:

1. Tokisetso ea Lisebelisoa tse Tala

- Tungsten CarbidePhofo: Thepa ea mantlha e sebelisoang makhasi a carbide ke tungsten carbide (WC), e leng motsoako o teteaneng le o thata oa tungsten le carbon. Mofuta oa phofo oa tungsten carbide o kopantsoe le tšepe e kopanyang, hangata cobalt (Co), ho thusa ka ts'ebetso ea ho sila.

- Ho Kopanya Phofo: Phofo ea tungsten carbide le cobalt li kopantsoe hammoho ho etsa motsoako o ts'oanang. Motsoako o laoloa ka hloko ho netefatsa hore motsoako o nepahetse bakeng sa ho thatafala le ho tiea ha lehare le lakatsehang.

2. Ho tobetsa

- Ho bopa: Motsoako oa phofo o kenngoa ka har'a hlobo kapa sehatsetsi ebe o hatelloa hore e be sebopeho se kopaneng, e leng sebopeho se bataletseng sa lehare. Hangata sena se etsoa tlas'a khatello e phahameng ts'ebetsong e bitsoangho hatella ka mokhoa o batang oa isostatic (CIP) or ho tobetsa ka uniaxial.

- Ho bopa: Nakong ea ho hatella, sebopeho se thata sa lehare sea thehoa, empa ha se so be thata ka botlalo kapa se sa tiea. Mochini o hatisang o thusa ho kopanya motsoako oa phofo ho ea ka sebopeho se lakatsehang, joalo ka sebopeho sa sesebelisoa sa ho seha kapa lehare.

3. Ho sila

- Ho Sintering ka Mocheso o Phahameng: Kamora ho hatella, lehare le feta ts'ebetsong ea ho sila. Sena se kenyelletsa ho futhumatsa sebopeho se hatelletsoeng ka ontong mochesong o tloaelehileng pakeng tsa1,400°C le 1,600°C(2552°F ho isa ho 2912°F), e leng se etsang hore likaroloana tsa phofo li kopane 'me li etse thepa e tiileng, e teteaneng.

- Ho Tlosa Binder: Nakong ea ho siloa, cobalt binder le eona ea sebetsoa. E thusa likaroloana tsa tungsten carbide ho khomarelana, empa kamora ho siloa, e boetse e thusa ho fa lehare thata le ho tiea ha lona la ho qetela.

- Ho pholisa: Kamora ho tjhesa, lehare le phodiswa butle-butle tikolohong e laolwang ho qoba ho petsoha kapa ho sotha.

4. Ho Sila le ho Bopa

- Ho sila: Kamora ho tjhesa, lehare la carbide hangata le ba le makukuno haholo kapa le sa tsitsane, kahoo le silwa ho ya ka boholo bo nepahetseng ho sebediswa mabili a ikgethang a kgokgotho kapa metjhini ya ho sila. Mohato ona o bohlokwa bakeng sa ho theha lehlakore le bohale le ho netefatsa hore lehare le fihlella ditshwaelo tse hlokahalang.

- Ho Bopa le ho Fana ka Profaele: Ho latela ts'ebeliso, lehare le ka 'na la fetoloa kapa la fetoloa ho ea pele. Sena se ka kenyelletsa ho sila likhutlo tse itseng moeling oa ho seha, ho sebelisa lipente, kapa ho lokisa sebopeho sa lehare ka kakaretso.

5. Mekhoa ea ho Qetela ea Kalafo

- Liaparo tsa Bokaholimo (Boikhethelo): Mahare a mang a carbide a fumana mekhoa e meng ea phekolo, joalo ka ho penta ka thepa e kang titanium nitride (TiN), ho ntlafatsa ho tiea, ho hanyetsa ho tsofala le ho fokotsa khohlano.

- Ho polisha: Ho ntlafatsa tshebetso haholoanyane, lehare le ka bentshwa ho fihlela bokaholimo bo boreleli, bo qetilweng bo fokotsang kgohlano le ho ntlafatsa bokgoni ba ho seha.

6. Taolo le Teko ea Boleng

- Teko ea ho tiea: Bothata ba lehare hangata bo lekoa ho netefatsa hore le fihlela litlhoko tse hlokahalang, ka liteko tse tloaelehileng ho kenyeletsoa le liteko tsa ho thatafala ha Rockwell kapa Vickers.

- Tlhahlobo ea litekanyo: Ho nepahala ho bohlokoa, kahoo litekanyo tsa lehare lia hlahlojoa ho netefatsa hore li fihlela mamello e nepahetseng.

- Teko ea Tshebetso: Bakeng sa lits'ebetso tse itseng, tse kang ho seha kapa ho seha, lehare le ka 'na la feta litekong tsa sebele ho netefatsa hore le sebetsa kamoo ho reriloeng kateng.

HUAXIN CARDINE E SIMENTITSOENG e fana ka lithipa le mahare a tungsten carbide a boleng bo holimo bakeng sa bareki ba rona ba tsoang liindastering tse fapaneng lefatšeng ka bophara. Mahare a ka hlophisoa ho lekana mechine e sebelisoang hoo e ka bang ts'ebelisong efe kapa efe ea indasteri. Lisebelisoa tsa lehare, bolelele ba lehlakore le liprofaele, mekhoa ea phekolo le lipente li ka fetoloa hore li sebelisoe le lisebelisoa tse ngata tsa indasteri.

Hang ha mahare a fetile diteko tsohle tsa boleng, a se a loketse ho sebediswa dikopong tse fapaneng tsa indasteri, tse kang ho sebetseng ka tshepe, ho paka, kapa mesebetsing e meng ya ho seha moo ho hanyetsa ho tsofala le ho ba bohale ho hlokahalang.

Nako ea poso: Pulungoana-25-2024