Mahare a tungsten carbide a tsebahala ka ho thatafala ha ona, ho hanyetsa ho tsofala, le ho fokotsa ts'ebetso ho pholletsa le liindasteri tse fapaneng. Leha ho le joalo, ho netefatsa hore a tsoela pele ho fana ka liphetho tse ntle ka ho fetisisa, tlhokomelo le ho leotsa hantle lia hlokahala. Sengoloa sena se fana ka likeletso tse sebetsang mabapi le ho hloekisa, ho leotsa le ho boloka mahare a tungsten carbide ho eketsa nako ea ona ea bophelo. Re tla boela re fane ka lintho tseo basebelisi ba li etsang le tseo ba sa lokelang ho li etsa bakeng sa liindasteri tse fapaneng, ho netefatsa hore mahare a hau a lula a le boemong bo holimo.

I. Ho Hloekisa Mahare a Tungsten Carbide

Ho lokela ho etsoa eng?

Ho Hloekisa Kamehla:

Theha mokhoa oa ho hloekisa makhasi a hau a tungsten carbide kamora tšebeliso e 'ngoe le e 'ngoe. Sena se tlosa lithōle, lerōle le litšila tse ling tse ka fifatsang lehare kapa tsa baka ho senyeha pele ho nako.

Sebelisa li-detergent tse bonolo:

Ha o hlwekisa, sebedisa sesepa se bobebe le metsi a futhumetseng. Qoba dikhemikhale tse bohale kapa dintho tse kgopang tse ka senyang bokahodimo ba lehare.

Omisa hantle:

Kamora ho hlwekisa, etsa bonnete ba hore lehare le omme hantle ho thibela mafome le ho bola.

Ke eng eo re sa lokelang ho e etsa?

Qoba Lisebelisoa tse sa Lokelang tsa ho Hloekisa:

Le ka mohla u se ke ua sebelisa ulu ea tšepe, borashe bo nang le li-bristle tsa tšepe, kapa thepa e 'ngoe e khorofo ho hloekisa mahare a tungsten carbide. Tsena li ka ngoapa bokaholimo 'me tsa fokotsa ts'ebetso ea ho seha.

Hlokomoloha Tlhoekiso e Tloaelehileng:

Ho tlola ho hlwekisa kamehla ho ka lebisa ho bokellaneng ha ditshila le ditshila, ho fokotsa nako ya ho phela ha lehare le bokgoni ba ho seha.

II. Ho Lokisa Mahare a Tungsten Carbide

1. Lintho tseo re ka li etsang ho leotsa lithipa tsa tungsten caibide

Sebelisa lisebelisoa tse khethehileng tsa ho lokisa moriri:

Tsetela ho disebediswa tse ikgethang tsa ho leotsa tse etseditsweng mahare a tungsten carbide. Disebediswa tsena di netefatsa ho leotsa ho nepahetseng le ho tsitsitseng, ho boloka botsitso ba lehlakore la lehare.

Latela Litaelo tsa Moetsi:

Kamehla latela litataiso tsa moetsi bakeng sa ho leotsa mekhahlelo le mekhoa. Ho leotsa ho feta tekano ho ka fokolisa sebopeho sa lehare, ha ho leotsa ho feta tekano ho ka fokotsa ts'ebetso ea ho seha.

Tlhahlobo e Tloaelehileng:

Hlahloba lehare khafetsa bakeng sa matšoao a ho tsofala kapa tšenyo. Sebetsana le mathata afe kapa afe kapele ho thibela ho senyeha ho eketsehileng.

2. Seo re sa lokelang ho se etsa

Qoba Mekhoa e sa Lokang ea ho Lokisa:

Le ka mohla u se ke ua leka ho leotsa mahare a tungsten carbide u sebelisa mekhoa kapa lisebelisoa tse sa lokelang. Sena se ka lebisa ho senyeheng ho sa lekanang, ho taboha, kapa ho petsoha ha lehare.

Ho hlokomoloha ho otlolla:

Ho hlokomoloha tlhoko ea ho leotsa lehare ho ka fifatsa lehare, ha fokotsa bokhoni ba ho seha le ho eketsa kotsi ea tšenyo nakong ea tšebeliso.

III. Litlhahiso mabapi le ho Boloka Mahare a Tungsten Carbide

Ka ho le letona:

Boloka Tikolohong e Omileng:

Boloka makhasi a tungsten carbide tikolohong e omileng, e se nang mafome ho thibela mafome.

Sebelisa Litšireletso tsa Mahare:

Ha e sa sebelisoe, boloka makhapetla ka har'a likhetla tse sireletsang kapa mabokoseng ho thibela tšenyo e sa lebelloang.

Beha Leibole le Hlophisa:

Tšoaea le ho hlophisa mahare a hao ho netefatsa hore ho bonolo ho a tseba le ho a fumana. Sena se fokotsa kotsi ea ho sebelisa lehare le fosahetseng bakeng sa ts'ebeliso e itseng.

Phoso:

Qoba ho pepesehela mongobo:

Le ka mohla u se ke ua boloka makhasi a tungsten carbide maemong a mongobo kapa a mongobo. Mongobo o ka baka mafome le mafome, e leng se fokotsang nako ea bophelo ba lehare.

Polokelo e sa Lokelang:

Poloko e sa lokelang, joalo ka ho siea mahare a pepesitsoe kapa a pakiloe ka mokhoa o sa phutholohang, ho ka lebisa tšenyo kapa ho fifala.

Litlhahiso tse ling mabapi le ho hlokomela lithipa tsa tungsten carbide tsa indasteri

Hlahloba di-blade kgafetsa hore na di a senyeha mme o di lokise ha ho hlokahala ho boloka ho nepahala ha ho seha.

Sebelisa lisebelisoa tse khethehileng tsa ho leotsa tse etselitsoeng mahare a tungsten carbide ho boloka lehlakore le bohale bakeng sa ho seha ka nepo.

Mabapi le Huaxin: Moetsi oa Lithipa tsa ho Senya tsa Tungsten Carbide tse samentetsoeng

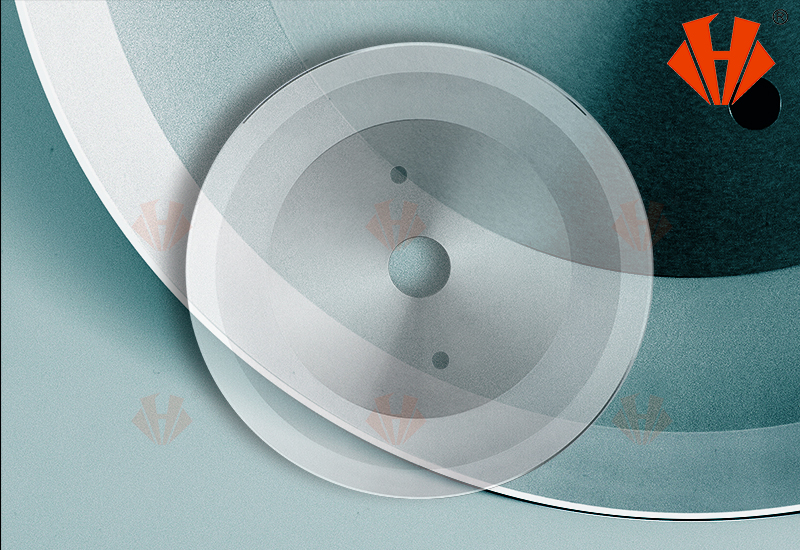

CHENGDU HUAXIN SAMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oa lihlahisoa tsa carbide tsa tungsten, tse kang lithipa tsa carbide tse kenngoang bakeng sa ho betla lehong, lithipa tse chitja tsa carbide bakeng sa ho seha lithupa tsa sefe ea koae le sakerete, lithipa tse chitja bakeng sa ho seha khateboto e nang le corugat, mahare a lehare a masoba a mararo/mahare a nang le masoba bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lihlahisoa tsa li-blade tsa indasteri tsa tungsten carbide tse sebetsang hantle haholo

Tšebeletso e Ikhethileng

Huaxin Cemented Carbide e etsa di-blade tsa tungsten carbide tse ikgethileng, di-blank tse fetotsweng tse tloaelehileng le tse tloaelehileng le di-preform, ho qala ka phofo ho isa di-blank tse fedisitsweng. Kgetho ya rona e felletseng ya dikereiti le tshebetso ya rona ya tlhahiso e fana ka disebediswa tse sebetsang hantle, tse tshepahalang tse bopehileng jwalo ka netweke tse sebetsanang le diphephetso tse ikgethang tsa tshebediso ya bareki diindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Phato-18-2025