Ts'ebetso ea Tlhahiso ea Carbide e Samenteng Hangata ho thoe ho ntlafatsa ts'ebetso ea ho sebetsa ka thata, liparamente tse tharo tsa bohlokoa tsa ho seha—lebelo la ho seha, botebo ba ho seha, le sekhahla sa ho fepa—li tlameha ho ntlafatsoa, kaha hangata ena ke mokhoa o bonolo le o tobileng ka ho fetisisa. Leha ho le joalo, ho eketsa liparamente tsena hangata ho lekanyelitsoe ke maemo a lisebelisoa tsa mochini tse seng li ntse li le teng. Ka hona, mokhoa o theko e tlaase le o bonolo ka ho fetisisa ke ho khetha sesebelisoa se nepahetseng. Lisebelisoa tsa carbide e samenteng hajoale ke tsona tse ka sehloohong 'marakeng oa lisebelisoa. Boleng ba carbide e samenteng bo khethoa ke lintlha tse tharo: matrix ea carbide e samenteng (skeleton), sebopeho le sebopeho sa lehare (nama), le ho roala (letlalo). Kajeno, re tla teba ka botebo lisebelisoa tsa ho sebetsa ka thata, ho tloha "skeleton ho ea nameng." Sebopeho sa Matrix ea Carbide e SamentengMatrix ea carbide e samenteng e na le likarolo tse peli tsa mantlha:

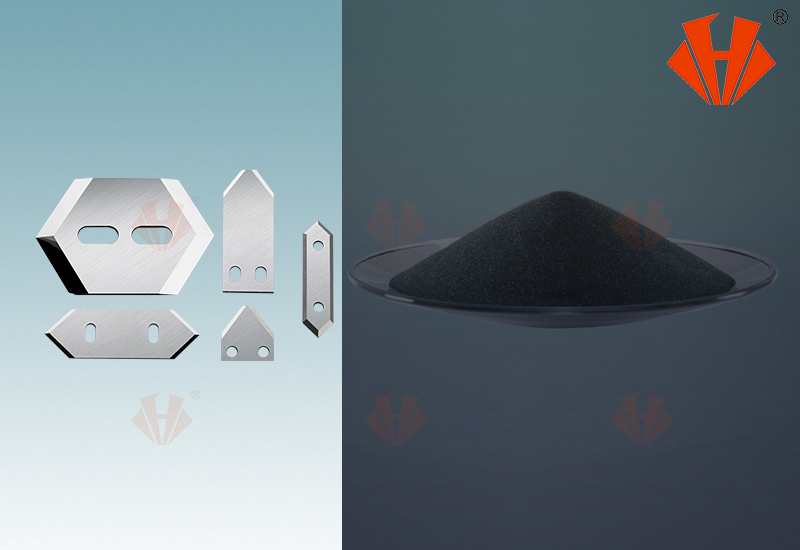

Mokhahlelo oa ho thatafatsa: Sena se kenyelletsa thepa e kang tungsten carbide (WC) le titanium carbide (TiC), e qalang e le phofo.

U se ke ua nyenyefatsa phofo ena—ke thepa ea mantlha ea lik'habohaedreite tsohle tse tšetsoeng ka samente.

Tlhahiso ea Carbide ea Tungsten:Carbide ea Tungsten e entsoe ka tungsten le carbon. Phofo ea Tungsten e nang le boholo bo tloaelehileng ba likaroloana tse 3-5 μm e kopanngoa le carbon black ka har'a leloala la bolo bakeng sa ho kopanya ka mokhoa o omileng. Kamora ho kopanya ka botlalo, motsoako o kenngoa ka har'a terei ea graphite 'me o futhumatsoa ka ontong ea ho hanyetsa graphite ho fihlela ho 1400-1700°C. Mochesong ona o phahameng, karabelo e hlahisa carbide ea tungsten.

Thepa:Carbide ea Tungsten ke thepa e thata haholo empa e robeha habonolo ka ntlha ea ho qhibiliha e fetang 2000°C, ka linako tse ling e feta 4000°C. E khetholla boima bo phahameng ba motsoako le ho hanyetsa ho tsofala ha oona.

Tšepe ea Binder: Hangata, litšepe tsa sehlopha sa tšepe tse kang cobalt (Co) le nickel (Ni) lia sebelisoa, 'me cobalt ke eona e atileng haholo ho tsa machining.

Mohlala, ha tungsten carbide e kopantswe le cobalt, dikahare tsa cobalt di bohlokwa bakeng sa thepa ya carbide e kentsweng ka samente. Dikahare tse ngata tsa cobalt di ntlafatsa ho tiya, ha dikahare tse tlase tsa cobalt di eketsa ho thatafala le ho hanyetsa ho tsofala.

Mokhoa oa Tlhahiso

1. Ho Lokisetsa Phofo (Ho Sila ka Metsi) Ka phaposing ea ho sila, thepa e tala e siloa ho fihlela boholo ba likaroloana tse lakatsehang tikolohong e nang le ethanol, metsi le lintho tse kopanyang lintho tse phelang. Ts'ebetso ena, e tsejoang e le ho sila ka metsi, e kenyelletsa ho eketsa metsoako ea tlhaho kapa e seng ea tlhaho e le lithuso tsa ho sila.

▶ Hobaneng ho Siloa ka Metsi?

▶Ho sila ho ommeng ho ka sila thepa feela ho fihlela boemong ba micron (mohlala, kaholimo ho 20 μm) hobane, ka tlase ho boholo bona, ho hohela ka motlakase ho baka ho kopana ho matla ha dikarolwana, e leng se etsang hore ho sila ho be thata haholoanyane.

▶Ho sila ka metsi, ka tšusumetso ea lithuso tsa ho sila, ho ka fokotsa boholo ba likaroloana ho ba li-micron tse 'maloa kapa esita le li-nanometer.

▶Nako: Ho latela thepa e tala, ho sila ka metsi ho nka dihora tse ka bang 8-55, e leng se fellang ka ho emisoa ho lekanang ha thepa e tala.

2. Ho Omisa ka Spray Motsoako wa mokelikeli o pompelwa ka hara spray dryer, moo kgase e chesang ya naetrojene e fetolang ethanol le metsi mouoane, e siya phofo e nang le boholo bo lekanang.

▶Phofo e omisitsweng e na le dikarolwana tse chitja tse bophara ba 20–200 μm. Ho beha sena ka pono e nepahetseng, phofo e ntle ka ho fetisisa e ka tlase ho halofo ea botenya ba moriri oa motho.

▶ Lero le omisitsweng le romelwa bakeng sa tlhahlobo ya boleng ho netefatsa botsitso.

3. Ho tobetsa Phofo e hlahlobiloeng e fepuoa ka har'a mochini o hatellang ho etsa lisebelisoa tse kenngoang.

▶Mofuta wa ho tobetsa o kenngwa ka hara mochini, mme ho phunya le ho tjhesa di laolwa ho hatella phofo hore e be sebopeho le boholo ba sesebediswa.

▶Ho latela mofuta oa ho kenya, khatello e hlokahalang e ka fihla ho lithane tse 12.

▶Kamora ho tobetsa, sehokelo se seng le se seng se beoa ho netefatsa boleng le ho nepahala.

4. Ho Sila Li-insert tse sa tsoa hatelloa lia fokola haholo 'me li hloka ho tiea ka sebōping se silang.

▶Li-insert li feta lihora tse 13 tsa kalafo ea mocheso ho 1500°C, moo cobalt e qhibilihisitsoeng e kopanang le likaroloana tsa tungsten carbide. Ho 1500°C, tšepe e ne e tla qhibiliha kapele joaloka tsokolate.

▶Nakong ea ho sila, polyethylene glycol (PEG) ka har'a motsoako oa fetoha mouoane, 'me bophahamo ba karolo e kenngoang bo fokotseha ka hoo e ka bang 50%, e leng se etsang hore ho be thata ho itseng.

5. Kalafo ea Bokaholimo (Ho Holisa le ho Koahela) Ho fihlela litekanyo tse nepahetseng, lintho tse kentsoeng lia holisoa ho sila bokaholimo bo ka holimo le bo ka tlase.

▶Kaha di-insert tsa carbide tse sintsitsoeng ka samente di thata haholo, mabili a daemane a indasteri a sebediswa bakeng sa ho sila ka nepo.

▶Mohato ona o hloka ho nepahala ho hoholo theknolojing ea ho sila. Mohlala, Sweden e sebelisa theknoloji e tsoetseng pele ea ho sila ea li-axis tse 6 ho fihlela litlhoko tse thata haholo tsa mamello.

Kamora ho sila, lintho tse kenngoang lia hloekisoa, lia koaheloa, 'me li hlahlojoa ka boleng ba ho qetela.

Hobaneng o lokela ho kgetha Chengduhuaxin Carbide?

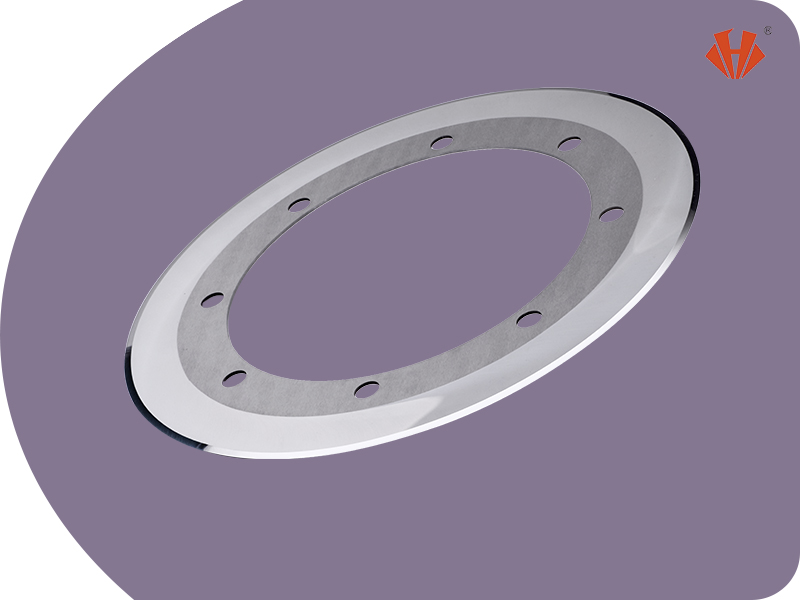

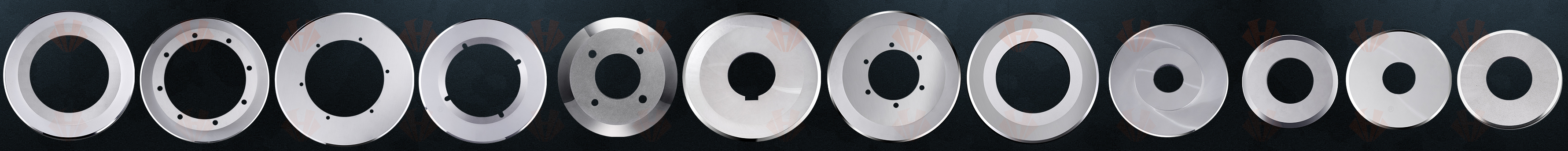

Chengduhuaxin Carbide e hlahella 'marakeng ka lebaka la boitlamo ba eona ba boleng le boqapi. Mahare a bona a k'hapete ea tungsten carbide le mahare a nang le tungsten carbide a entsoe bakeng sa ts'ebetso e phahameng, a fa basebelisi lisebelisoa tse fanang ka ho seha ho hloekileng le ho nepahala ha ts'ebeliso e boima ea indasteri. Ka ho tsepamisa maikutlo ho tšoarelleng le ho sebetsa hantle, mahare a nang le likheo a Chengduhuaxin Carbide a fana ka tharollo e phethahetseng bakeng sa liindasteri tse hlokang lisebelisoa tse tšepahalang tsa ho seha.

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oalihlahisoa tsa tungsten carbide,tse kang lithipa tsa ho kenya carbide bakeng sa ho betla lehong, carbidelithipa tse chitjabakeng saho phunya lithupa tsa sefe sa koae le sakerete, lithipa tse chitja bakeng sa ho petsoha ha khateboto e nang le korugate,mahare a lehare a masoba a mararo/mahare a nang le dikotwana bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a sehang faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Phupu-18-2025