Mahare a ho Seha a Fiber ea Lik'hemik'hale kapa lehare la ho seha la fiber ea Staple

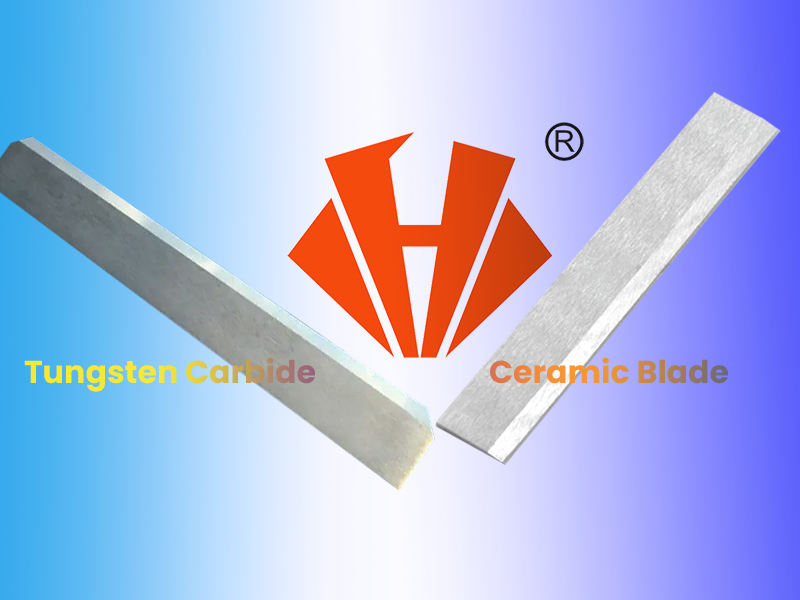

SLi-blade tsa Tungsten Carbide (STC) tse tiileng le tse tiileng tsa Ceramic ka bobeli ke lisebelisoa tsa ho seha tse sebetsang hantle, empa li na le thepa le lits'ebetso tse fapaneng ka lebaka la phapang ea thepa ea tsona. Mona ke papiso ea lits'ebetso tsa tsona ho latela liphapang tsa bohlokoa:

1. Sebopeho le Thepa ea Thepa

E tiilengLi-blades tsa Tungsten Carbide

- Sebopeho: E entsoe ka tungsten carbide, e leng motsoako oa tungsten le carbon, hangata e kopantsoeng le cobalt.

- Bothata: E thata haholo (e haufi le daemane ka tekanyo ea boima), empa ha e robehe habonolo joaloka letsopa.

- Ho tiea: E fana ka ho tiea ho hoholo, ho bolelang hore e ka sebetsana le litšitiso le ho seha ka khatello e phahameng ho feta liseramike.

- Ho hanyetsa ho apara: E hanyetsa ho tsofala haholo, e loketse tšebeliso ea nako e telele libakeng tsa indasteri.

Mahare a Tiileng a Ceramic

- Sebopeho: Hangata e etsoa ka thepa e kang zirconia kapa silicon carbide.

- Bothata: E thata le ho feta tungsten carbide, empa e robeha habonolo haholo.

- Ho tiea: Ho tiea ho tlase ha ho bapisoa le carbide, e leng se etsang hore e be kotsing ea ho qhaqhoa kapa ho robeha habonolo ha e thulana.

- Ho hanyetsa ho apara: Hape e hanela ho tsofala haholo empa e ka tsofala ka ho se leka-lekane ha e sebelisoa linthong tse bonolo.

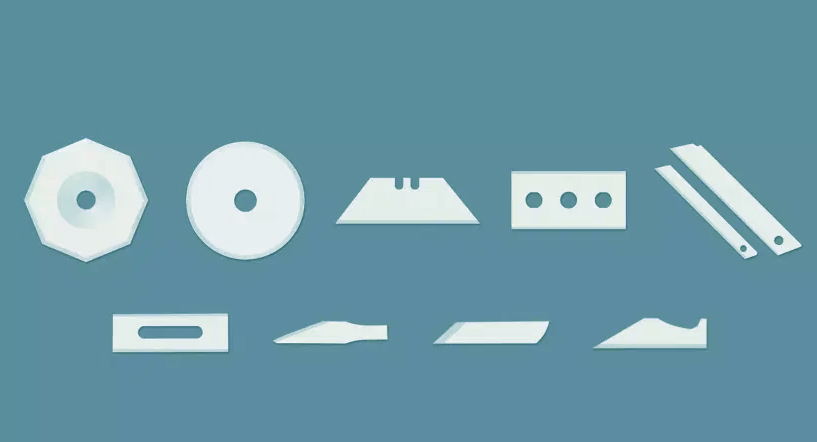

2. Likopo

Li-blades tsa Tungsten Carbide tse tiileng:

- Ho Seha Tšepe le Lintho tse Kopantsoeng: E kgethwa lits'ebetsong tse boima tse kang ho seha kapa ho sebetsa ka tšepe, metsoako le thepa e meng e thata.

- Ho Seha ka ho Sebetsa: E sebelisoa lits'ebetsong tse hlokang tekano pakeng tsa bohale le ho tšoarella, joalo ka ho petsoha ha indasteri (mohlala, lifoile tsa tšepe, lifilimi le pampiri).

- Ts'ebetso ea Khatello e Phahameng: E loketse mesebetsi e kenyeletsang khatello e phahameng ea ho seha, joalo ka ho cheka, ho sila le ho sila liindastering tse kang likoloi, lifofane le tlhahiso.

- Nako e Telele ea Bophelo Maemong a Tšusumetso: E loketse mechini moo lehare le ka bang le tshusumetso kapa thothomelo ka lebaka la ho tiea ha lona.

Mahare a Tiileng a Ceramic:

- Ho Seha ka ho Nepahetseng ha Lisebelisoa tse Bonolo: E sebelisoa lits'ebetsong tse nepahetseng tse kang filimi ea ho seha, fiber optics, polasetiki le masela. Bohloko bo feteletseng bo fana ka bohale bo ikhethang empa hangata bo boloketsoe lisebelisoa tse sa khorofong haholo.

- Mesebetsi ea Mocheso o Phahameng: E loketse dibakeng tseo mocheso o phahameng o ka amang disebediswa tsa ho seha, kaha diserame di ka boloka thepa ya tsona mochesong o feteletseng.

- Khanyetso ea ts'enyeho: Hangata e khethoa libakeng tseo ho pepesehela lik'hemik'hale kapa mongobo ho ka senyang mahare a tšepe, joalo ka ts'ebetsong ea lijo, lits'ebetsong tsa bongaka le indastering ea lik'hemik'hale.

- Likopo tse Bonolo: E sebelisoa maemong ao thepa e leng bonolo, 'me lehare le tlameha ho fana ka likarolo tse ntle haholo, tse hloekileng (mohlala, ho tsa elektroniki, tlhahiso ea semiconductor).

3. Mehopolo ea Ts'ebetso

Li-blades tsa Tungsten Carbide tse tiileng:

- E loketse haholo bakeng sa lits'ebetso tsa ho seha tse nang le khatello e phahameng ka lebaka la ho tiea ha eona.

- E ka lokisoa hape ka makhetlo a mangata, e leng se eketsang nako ea eona ea bophelo.

- Ho mamella ho hoholo ha thepa e kgopang jwalo ka ditshipi le metswako e teteaneng.

Mahare a Tiileng a Ceramic:

- E loketse haholo ha tikoloho ea ho seha e hloka karabelo e nyane haholo ka thepa e sehiloeng (mohlala, mahare a bongaka).

- Ha li mamelle tšusumetso hakaalo, kahoo li sebelisoa maemong a thothomelang ka tlase le a nepahetseng haholo.

- Ka tlwaelo, ha e kgone ho lokiswa ha bonolo, e leng se etsang hore e be kgetho e lahlwang maemong a mang.

- Li-blades tsa Tungsten Carbideli ratoa haholo lits'ebetsong tsa indasteri moo ho tiea, ho tšoarella le ho hanyetsa ho tsofala tlas'a khatello e leng tsa bohlokoa, haholo-holo ka thepa e thata kapa e khorofong haholo.

- Mahare a letsopaLi ipabola maemong a nepahetseng, a sa arabeleng, le a mocheso o phahameng, li seha thepa e bonolo le maemong ao ho hanyetsa lik'hemik'hale ho leng bohlokoa haholo. Ha lia lokela maemo a nang le tšusumetso e matla kapa a khatello e phahameng ka lebaka la ho robeha ha tsona habonolo.

Liphapang tsena li tataisa khetho ea mofuta o mong le o mong oa lehare ho latela litlhoko tse ikhethileng tsa ts'ebetso ea ho seha.

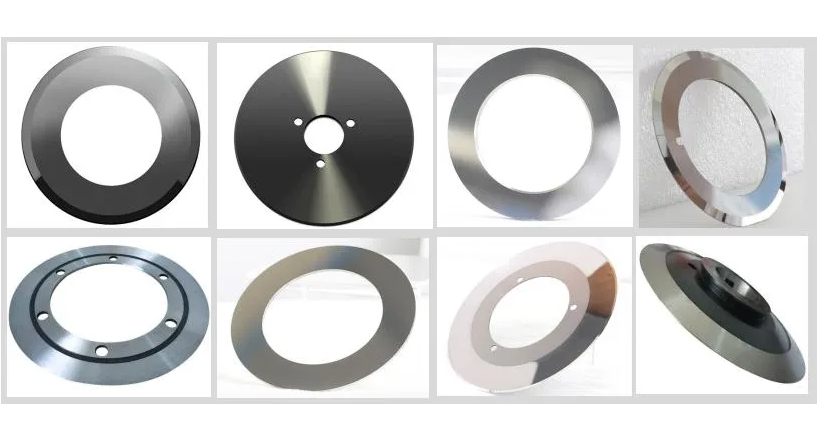

HUAXIN CEMENTED CARBIDE e fana ka lithipa le mahare a tungsten carbide a boleng bo holimo bakeng sa bareki ba rona ba tsoang liindastering tse fapaneng lefatšeng ka bophara. Mahare a ka hlophisoa ho lekana mechini e sebelisoang hoo e ka bang ts'ebelisong efe kapa efe ea indasteri. Lisebelisoa tsa lehare, bolelele ba lehlakore le liprofaele, mekhoa ea phekolo le lipente li ka fetoloa hore li sebelisoe le lisebelisoa tse ngata tsa indasteri.

Nako ea poso: Mphalane-29-2024