Mahare a tungsten carbide ke disebediswa tsa bohlokwa indastering ya tlhahiso ya difilimi, tse tsebahalang ka ho tshwarella ha tsona le ho nepahala ha tsona. Mahare ana a sebetsang hantle a sebediswa hangata mechineng ya ho seha ho fihlella ho kgaola ho nepahetseng hodima meqolo ya difilimi, ho netefatsa bophara bo tshwanang bo bohlokwa bakeng sa ho paka le ditshebediso tse ding.

Ntle le ho seha, lithipa tsa carbide li bapala karolo ea bohlokoa lits'ebetsong tsa ho seha ka die. Li theha libopeho le meralo e rarahaneng e nang le mathoko a hloekileng, e leng se ntlafatsang botle ba lihlahisoa tse thehiloeng filiming joalo ka mabitso. Ho feta moo, mahare a carbide a tungsten a bohlokoa ts'ebetsong ea ho sebelisa hape, moo a thusang ho pshatla lifilimi tsa polasetiki bakeng sa ho li sebelisa hape ka katleho, ho kenya letsoho phokotsong ea litšila le botsitso.

Nakong ea ho ntša filimi, mahare a tšepe e thata a thusa ho kuta thepa e feteletseng, ho boloka botenya bo lakatsehang le ho netefatsa tlhahiso ea boleng bo holimo. Litšobotsi tsa tsona tse hanelang ho khoptjoa li etsa hore li be ntle bakeng sa ho sebetsana le thepa e thata joalo ka li-polyfilm le li-substrate tse tenyetsehang.

Tšebeliso ea Li-blade tsa Tungsten Carbide Indastering ea Tlhahiso ea Lifilimi

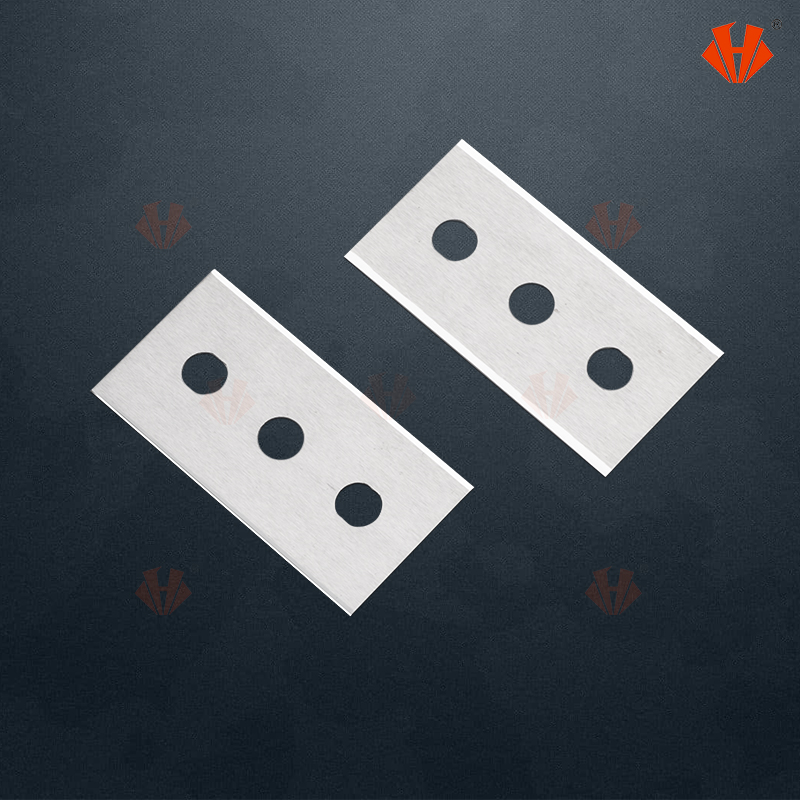

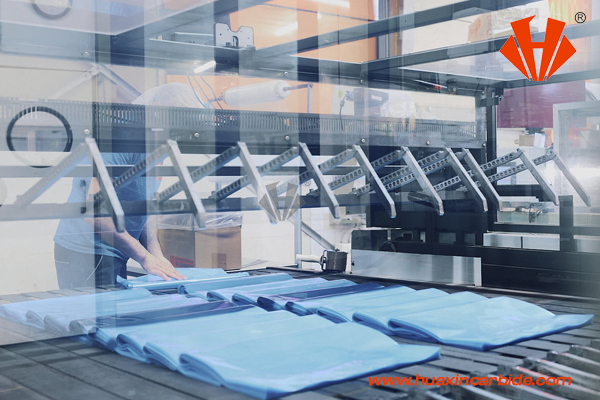

Sehahi sa Faeba sa Tungsten CarbideLi bapala karolo ea bohlokoa indastering ea tlhahiso ea lifilimi, haholo-holo lits'ebetsong tse kenyeletsang ho seha le ho seha mefuta e fapaneng ea lifilimi. Mahare ana a tsebahala ka ho thatafala ha 'ona le ho tšoarella ha 'ona ka tsela e ikhethang, e leng se etsang hore a be matle bakeng sa ho seha ka har'a thepa e thata joalo ka polyfilms, lifilimi tsa ho paka, le li-substrate tse ling tse tenyetsehang.

Likopo tsa Bohlokoa:

- Ho Seha le ho Seha:Mahare a tungsten carbide a sebediswa mechineng ya ho seha ho fihlella ho kgaolwa ho nepahetseng hodima meqolo ya filimi. Ho nepahala hona ho bohlokwa bakeng sa ho hlahisa bophara bo tshwanang ba filimi, e leng ntho ya bohlokwa bakeng sa ho paka le ditshebediso tse ding.

- Ho Seha ka Die:Tlhahisong ea mabitso le lihlahisoa tse ling tse thehiloeng filiming, mahare a tungsten carbide a sebelisoa lits'ebetsong tsa ho seha ka dies ho theha libopeho le meralo e rarahaneng ka mathoko a hloekileng.

- Mesebetsi ea ho sebelisa hape:Mahare ana a boetse a sebelisoa libakeng tsa ho sebelisa lintho hape, moo a thusang ho pshatla lifilimi tsa polasetiki bakeng sa ho li sebelisa hape, ho netefatsa hore thepa e khutlisoa hantle le hore e fokotsoe.

- Ho Ntša Filimi:Meleng ea ho ntša filimi, mahare a tungsten carbide a thusa ho fokotsa thepa e feteletseng le ho boloka botenya bo lakatsehang ba filimi, e leng se tlatsetsang tlhahisong ea boleng bo holimo.

Tšebeliso ea makhasi a tungsten carbide indastering ea tlhahiso ea lifilimi e netefatsa katleho e phahameng, boleng bo holimo le bophelo bo bolelele, e leng se etsang hore e be sesebelisoa sa bohlokoa bakeng sa bahlahisi.

Mahare a tungsten carbide, hammoho le lisebelisoa tse amanang le ho seha le mahare a indasteri, a bohlokoa haholo indastering ea tlhahiso ea lifilimi. Ho tšepahala ha tsona le ts'ebetso ea tsona ho ntlafatsa haholo bokhoni le boleng ba sehlahisoa, e leng se etsang hore e be khetho e ratoang bakeng sa bahlahisi ba batlang ho nepahala le ho phela nako e telele lits'ebetsong tsa bona tsa ho seha.

HUAXIN CARDINE E SIMENTITSOENGe fana ka lithipa le mahare a tungsten carbide a boleng bo holimo bakeng sa bareki ba rona ba tsoang liindastering tse fapaneng lefatšeng ka bophara. Mahare a ka hlophisoa ho lekana mechine e sebelisoang hoo e ka bang ts'ebelisong efe kapa efe ea indasteri. Lisebelisoa tsa lehare, bolelele ba lehlakore le liprofaele, mekhoa ea phekolo le lipente li ka fetoloa hore li sebelisoe le lisebelisoa tse ngata tsa indasteri.

Nako ea poso: Tshitwe-25-2025