TSistimi ea Lisebelisoa tsa ho Potoloha/Ho Hlalosa le Mahare a Tsona Mosebetsing oa ho Betla Lehong

Lefapheng la ho betla lehong, ho eketsoa ha sebopeho le di-spiral dikotwaneng tse retolotsweng ha ho ekelle feela kgahleho ya pono empa hape ho eketsa thahasello e amang, ho fetola dibopeho tse bonolo hore e be mesebetsi ya bonono. Sistimi ya ho Potoloha/Ho Teka ke sete e ikgethang ya disebediswa tse reretsweng ho ntlafatsa diporojeke tsa ho betla lehong ka dipaterone tse rarahaneng, di-spiral le dibopeho. Mona, re hlahloba sistimi ena, dikarolo tsa yona, le hore na ke hobaneng ha di-blades tsa tungsten carbide e le kgetho e ntle bakeng sa disebediswa tsena.

Ho utloisisa Sistimi ea ho Potoloha/Ho Hlalosa

Kakaretso ea Lisebelisoa tsa ho Phetla le ho Sebetsa ka Mebala:

Sesebelisoa sa ho Sebetsa ka Mebala: Sesebelisoa sena se eketsa mebala e ikhethang holim'a lehong, se etsa hore ho be le liphello tse kang striations, whorls, kapa qetello ea letlalo la lamunu. Hangata se na le seha se ka fetoloang se ka sebetsang holim'a lifate tse bonolo le tse thata, leha sephetho se ka fapana ho latela thollo ea lehong le bongata ba lona.

Sesebelisoa sa ho Korotla: Ha di sebediswa bakeng sa ho etsa dikorotla kapa diforo, disebediswa tsena di ka hlahisa dikorotla tse ka letsohong le letshehadi le le letona. Hangata di tla le sistimi e kenyeletsang phomolo ya sesebediswa e nang le maemo a ngotsweng bakeng sa ho pheta-pheta ho tsitsitseng ha dikorotla. Boholo bo fapaneng ba bophahamo bo ka fihlellwa ka ho fetola seha kapa ho lokisa sekhutlo sa sesebediswa.

Likarolo tsa Bohlokoa:

- Mohele: Hangata o entsoe ka lehong bakeng sa boiketlo le taolo, o lumella tšebeliso e telele ntle le mokhathala.

- Phomolo ea Sesebelisoa: Karolo ea bohlokoa ea sistimi e potolohang, e nolofalletsang taolo e nepahetseng holim'a sekhutlo le botebo ba sehiloeng.

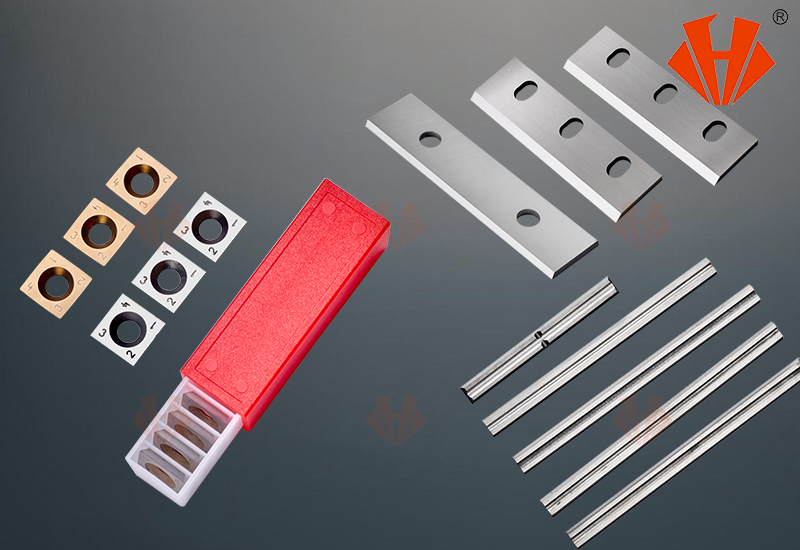

- Li-cutter: Pelo ea lisebelisoa tsena, e fumaneha ka mekhoa e fapaneng:

- Li-cuttering Cutting: Tsena li tla ka moralo o le mong kapa ho feta, hangata li na le lehlakore le nang le li-beveled tse peli kapa profil e itseng ho etsa li-texture tse fapaneng.

- Li-cutter tse potolohang: Li fumaneha ka lihlopha, hangata li kenyelletsa li-pitch tse fapaneng (joalo ka 2mm, 4mm, 6mm) ho fihlela liphello tse fapaneng tsa spiral.

Melemo ea Li-blade tsa Tungsten Carbide

Ha ho tluoa tabeng ea mahare a sebelisoang lisebelisoa tsa ho phutholla le ho taka, tungsten carbide e ikhetha ka mabaka a 'maloa a susumetsang:

Ho tšoarella:

Carbide ea tungsten e tumme ka ho thatafala ha eona (e feta daemane feela), ho bolelang hore mahare ana a boloka bohale ba 'ona bo le telele haholo ho feta mahare a tšepe a setso. Ho tšoarella hona ho fetolela nako e telele ea lisebelisoa, ho fokotsa makhetlo a ho nkeloa sebaka le ho leotsoa.

Ho Boloka Moeli:

Ho boloka mahlakore a tungsten carbide hantle ho netefatsa hore sehiloeng se seng le se seng se dula se nepahetse ha nako e ntse e ya, e leng sa bohlokwa bakeng sa ho fihlella dipaterone tse tsitsitseng tsa ho taka le ho potoloha. Boleng bona bo molemo haholo ho betleng lehong moo ho nepahala ho ka etsang phapang e kgolo ya botle.

Ho feto-fetoha ha maemo:

Mahare ana a ka seha mefuta e fapaneng ya difate, ho tloha ho tse bonolo ho isa ho tse thata, ntle le ho lahlehelwa ke bohale ba tsona kapele. Ho tenyetseha ha tsona ho etsa hore e be tse loketseng batho ba sebetsang ka mefuta le diporojeke tse fapaneng tsa difate.

Tlhokomelo e Fokolitsoeng:

Leha mahare a tungsten carbide a ka ba thata ho a leotsa ka lebaka la ho thatafala ha ona, tlhoko ea ho leotsa ha e atisehe haholo. Ntlha ena e khahla haholo-holo ba batlang ho fokotsa litšenyehelo tsa nako ea ho sebetsa le tsa tlhokomelo.

Bokgoni:

Bokhoni ba ho seha lehong ka mokhoa o hloekileng ka boiteko bo fokolang ha bo potlakise feela ts'ebetso empa hape bo fokotsa khatello ea 'mele ho setsebi sa lehong, e leng se lumellang meralo e rarahaneng haholoanyane ka boiteko bo fokolang.

Likopo le Lintho Tse ka Nahanoang

- Ditshebediso: Disebediswa tsena di sebedisetswa ho khabisa dintho tse retolotsweng jwalo ka dikotlolo, di-spindle, dikerese le dikotlolo, ho fana ka karolo ya mokhabiso e ka bang bonolo kapa ya tuma ho latela mokgwa le sesebediswa se sebedisitsweng.

- Lintho Tse Lokelang ho Etsoa: Le hoja mahare a tungsten carbide e le letsete le letle, a tla le litšenyehelo tse phahameng tsa pele. Leha ho le joalo, nako e telele ea tsona le ts'ebetso ea tsona hangata li lokafatsa litšenyehelo tsena. Hape, basebelisi ba lokela ho ela hloko tlhoko ea mehato e loketseng ea polokeho ha ba sebetsa ka lisebelisoa tsena ka lebaka la bohale ba tsona le lerōle la patsi le hlahang.

TSistimi ea Lisebelisoa tsa ho Koahela/Ho Tekanya, e nang le mahare a tungsten carbide, e emela sehlohlolo sa theknoloji ea lisebelisoa tsa ho betla lehong, e fanang ka taolo e sa bapisoeng, ho nepahala le ho tšoarella. Hore na u setsebi sa ho betla lehong kapa motho ea ratang ho itlosa bolutu, ho tsetela lisebelisoa tsena ho ka phahamisa merero ea hau ea ho betla lehong haholo, ho fana ka melemo ea bonono le ea ts'ebetso. Hopola, khetho ea thepa bakeng sa mahare a hau e bohlokoa joalo ka mokhoa; tungsten carbide ha e eme feela ho fihlela mosebetsi empa e ipabola ho oona.

Lithipa tsa Planer tse ka fetoloangLi entsoe ka sehlopha sa carbide sa boleng bo holimo 'me li hlahlojoa ka bonngoe ho netefatsa boleng le ho nepahala. Li-blade tsa planer li sebelisoa ha ho sebetsoa holim'a libaka tsa lehong ho thusa ho theha libaka tse reriloeng hantle. Li ka boela tsa sebelisoa ho shapa, le ho lahla mathoko. Boholo ba lehare bo bolela boholo ba planer eo e tla e lekana. E tla tšoarella ho feta mathoko a tloaelehileng a HSS bonyane ka makhetlo a 20 'me e hlahise qetello e boreleli le e hloekileng.

Bahlahisi ba Huaxin Cemented Carbidemahare a tungsten carbideLi-blank le li-preform tse ikhethileng, tse fetotsoeng tse tloaelehileng le tse tloaelehileng, ho qala ka phofo ho isa ho li-blank tse felileng. Khetho ea rona e felletseng ea limaraka le ts'ebetso ea rona ea tlhahiso e fana ka lisebelisoa tse sebetsang hantle, tse tšepahalang tse nang le sebopeho se haufi le netweke tse sebetsanang le liphephetso tse ikhethang tsa ts'ebeliso ea bareki liindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

www.huaxincarbide.com

contact: lisa@hx-carbide.com

Nako ea poso: Pherekhong-11-2025