Ka tsoelo-pele e tsoelang pele ea saense ea thepa, nts'etsopele le ts'ebeliso ea carbide e khethehileng ea tungsten e hanelang mafome e tla atolosa mefuta e mengata ea ts'ebeliso ea maqeba a carbide ea tungsten. Ka ho eketsa likarolo tsa ho kopanya, ho ntlafatsa lits'ebetso tsa kalafo ea mocheso, le ho ntlafatsa mahlale a kalafo ea bokaholimo, maqeba a carbide ea tungsten ea nakong e tlang a lebelletsoe ho boloka ts'ebetso e ntle haholo libakeng tse fapaneng tse senyang, ho fana ka litharollo tsa ts'ebetso tse tšepahalang le tse sebetsang hantle bakeng sa liindasteri tse fapaneng.

1. Mabapi le Li-blade tsa Tungsten Carbide

Carbide ea Tungsten, eo ka molao e tsejoang e le carbide e samentetsoeng, ke thepa ea motsoako e entsoeng haholo-holo ka carbide ea tungsten, e hlahisoang ka ts'ebetso ea tšepe ea phofo. E khetholloa ka ho ba thata haholo le ho hanyetsa ho tsofala ho hoholo, e boloka bothata ba eona bo sa fetohe esita le ho 500°C 'me e ntse e e-na le thata e phahameng ho 1000°C. Tshebetso ena e ikhethang e etsa hore carbide ea tungsten e be khetho e ntle bakeng sa ho etsa lisebelisoa tsa ho seha tse sebetsang hantle, tse sebelisoang haholo lisebelisoa tse fapaneng tsa ho seha tse kang lisebelisoa tsa lathe, li-silling cutters, li-planer, li-drill le lisebelisoa tse tenang.

Mahare a sejoale-joale a tungsten carbide a entsoe haholo-holo ka likarolo tse peli tsa motheo: tungsten carbide le cobalt. Karolo e thata ea tungsten carbide e fana ka boima bo feteletseng le khanyetso ea ho tsofala e hlokahalang bakeng sa lehare, ha karolo ea cobalt binder e fana ka boima bo itseng ho thepa. Moetsong o tloaelehileng oa lehare la tungsten carbide, tungsten carbide le cobalt li etsa 99% ea kakaretso, 'me litšepe tse ling li etsa 1%. Sebopeho sena se ikhethang sa microstructure se fa mahare a tungsten carbide boima bo ke keng ba fihlelloa ke tšepe e potlakileng le khanyetso ea ho tsofala e fetang haholo ea tšepe e tloaelehileng ea lisebelisoa, e tšoereng boemo ba bohlokoa tšimong ea ts'ebetso ea mechini.

Ka tsoelo-pele ea saense ea thepa, lelapa la tungsten carbide le lona le ntlafalitse mefuta e fapaneng e ikhethang, ho kenyeletsoa letoto le lengata la li-carbide tse kang tungsten carbide e sa tsofaleng haholo, tungsten carbide e sa tsofaleng haholo, tungsten carbide e sa tsofaleng mochesong o phahameng, tungsten carbide e seng ea makenete, le tungsten carbide e nang le likarolo tse ntle tse ntle. Lisebelisoa tsena tsa tungsten carbide tse entsoeng ka tsela e fapaneng li fana ka litharollo tse ntlafalitsoeng bakeng sa maemo a fapaneng a ts'ebeliso e itseng. Mohlala, tungsten carbide e sa tsofaleng e sebelisoang libakeng tsa lik'hemik'hale e ka eketsa likarolo tsa motsoako joalo ka chromium le nickel ho ntlafatsa haholo thepa ea eona ea ho thibela ts'enyeho.

Papiso ea Tshebetso ea Lisebelisoa tsa Lehare le Tloaelehileng

| Mofuta oa Boitsebiso | Boima (HRA) | Ho hanyetsa ho apara | Ho tiea | Khanyetso ea ts'enyeho |

| Tungsten Carbide e nang le samente Carbide | 89-95 | Holimo ka ho Fetisisa | Mahareng | Bohareng ho isa ho Botle |

| Tšepe e Potlakileng | 80-85 | Mahareng | Ho lokile | Mahareng |

| Sesebelisoa sa Tšepe | 70-75 | Mahareng | Ho lokile | Mahareng |

| Mahare a letsopa | 92-95 | Holimo ka ho Fetisisa | Tlase | E babatsehang |

Tlhahlobo ea Ts'ebetso ea Khanyetso ea Maqhubu a Tungsten Carbide

1. Mekhoa le Litšobotsi tsa ho Hanela ho Silafala

Ho hanyetsa ho bola ha mahare a tungsten carbide haholo-holo ho bakoa ke sebopeho sa tsona se ikhethang sa lik'hemik'hale le sebopeho sa micro. Carbide ea motheo ea tungsten e na le tungsten carbide le cobalt. Carbide ea tungsten ka boeona e na le botsitso bo boholo ba lik'hemik'hale 'me e ka hanela khoholeho ea mobu ke mecha e fapaneng ea litaba. Karolo ea cobalt binder e ka boela ea etsa lera la oxide le sireletsang mochesong oa kamore, e leng se fokotsang ts'ebetso ea ho bola. Litšebelisong tse sebetsang, tungsten carbide e bontša khanyetso e itseng ho li-acid, alkalis, metsi a letsoai le lik'hemik'hale tse ling, e e lumellang ho boloka ts'ebetso e tsitsitseng libakeng tse fapaneng tse senyang.

Diphuputso di bontsha hore kganyetso ya ho bola ha tungsten carbide e ntle haholo dibakeng tse itseng. Mohlala, ditekong tsa ho bola ha metsi a aluminium, sekgahla se tloaelehileng sa ho bola ha tungsten e hlwekileng ke hoo e ka bang 1/14 feela ya tshepe ya H13, e bontshang kganyetso e ntle ya ho bola. Tshebetso ena e phahameng ya ho lwantsha ho bola e etsa hore tungsten carbide e be mokhoa o mong o sebetsang ho feta tshepe ya setso indastering ya di-foundry le dibakeng tsa dikhemikhale tse nang le mocheso o phahameng. Ka ho tshwanang, ditekong tsa ho bola ha di-alloy tsa tungsten tse nang le matla a khoheli a phahameng, bafuputsi ba fumane hore thepa ena ka kakaretso e na le kganyetso e matla ya ho bola, e boloka botsitso ba motheo ba sebopeho kamora diteko tsa ho bola tsa ho qoelisoa ka laboratoring le diteko tsa ho pepesehela tikoloho ya tlhaho.

2. Litšobotsi tsa Bokaholimo le Boitšoaro ba ho Silafala

Ho hanyetsa ho bola ha mahare a tungsten carbide ha ho itshetlehe feela ka thepa ka boyona empa hape ho itshetlehile haholo ka boemo ba yona ba bokahodimo le ka mora ho sebetswa. Bokahodimo bo sitsweng hantle le bo bentshitsweng ba lehare la tungsten carbide bo ka etsa lera le sireletsang ka microscopic, le thibelang ho kenella ha metswedi e senyang. Mahare a mang a tungsten carbide a maemo a hodimo le ona a sebedisa mahlale a ho kwahela bokahodimo (jwalo ka TiN, TiCN, DLC, jj.), ao e seng feela a ntlafatsang tshebetso ya ho seha lehare empa hape a ntlafatsang ho hanyetsa ho bola haholo.

Ho bohlokoa ho hlokomela hore khanyetso ea tungsten carbide ha e felle ka ho feletseng. Lithuto li bontša hore tlas'a ho pepesehela tikoloho ea tlhaho nako e telele, karolo ea binder thepa ea alloy ea tungsten e na le tšekamelo e itseng ea ho bola, e leng se ka lebisang ho fokotseha ha polasetiki ea thepa. Ketsahalo ena e boetse e teng ho tungsten carbide e tloaelehileng e nang le karolo ea cobalt binder. Ha e le libakeng tse itseng tse senyang tse kang mongobo le spray ea letsoai, karolo ea cobalt e ka 'na ea bola ka mokhoa o khethehileng, ka hona ea ama ts'ebetso eohle ea lehare. Ka hona, ho khetha maemo a tungsten carbide a sa bolaeng ka ho khetheha ho bohlokoa haholo maemong a ts'ebeliso a nang le likotsi tse phahameng tsa ho bola.

3. Nts'etsopele le Tswelopele ea Tungsten Carbide e Hanelang Mafome

Ho fihlela litlhoko tsa ts'ebeliso libakeng tse feteletseng tse kang liindasteri tsa lik'hemik'hale le tsa leoatle, bo-rasaense ba thepa ba hlahisitse mehlala e entsoeng ka ho khetheha ea tungsten carbide e sa senyeheng ke mafome. Li-carbide tsena tse tsoetseng pele tsa tungsten li ntlafatsa botsitso ba lik'hemik'hale ba thepa haholo ka ho eketsa likarolo tsa ho kopanya tse kang chromium, nickel le molybdenum foromong ea setso. Mohlala, lehare la fiber ea lik'hemik'hale tse entsoeng ka patented le sa senyeheng ke mafome a sulfuric acid ka katleho le fokotsa ho robeha ha carbide ea tungsten ka boeona ka mekhoa e khethehileng ea ho temperating, forging, le ho tima oli ka mocheso, ha ka nako e ts'oanang le fa lehare khanyetso e ntle khahlanong le mafome a sulfuric acid.

| Mofuta oa Tikoloho | Tekanyo ea ts'enyeho | Foromo e ka Sehloohong ea Ts'enyeho | Tshebetso |

| Tikoloho ea Sepakapaka se Tikolohileng | Tlase Haholo | Ho ntša oksijene hanyane | E babatsehang |

| Tikoloho e nang le asiti (pH<4) | Bohareng ho isa ho Holimo | Kgetho ya Tshenyo ya Phase ya Binder | E Hloka Kereiti e Ikhethang |

| Tikoloho ea Alkaline (pH>9) | Tlase ho isa Mahareng | Tšilafalo ea Bokaholimo bo Tšoanang | Ho tloha ho Lokileng ho ea ho Botle |

| Tikoloho ea Metsi a Letsoai/Maoatle | Mahareng | Ho phunya, ho bola ha lefika | E Hloka Mehato ea Tšireletso |

| Tšepe e Qhibilihisitsoeng e Mocheso o Phahameng | Tlase | Karabelo ea Interfacial | E babatsehang |

Boitšoaro ba ho senyeha ha thepa ea Tungsten Carbide libakeng tse fapaneng

Tlhahlobo ea ho Lokela ha Tikoloho: Maemo ao Tungsten Carbide Blades e Lekaneng ho Atoloha

Mabapi le Huaxin: Moetsi oa Lithipa tsa ho Senya tsa Tungsten Carbide tse samentetsoeng

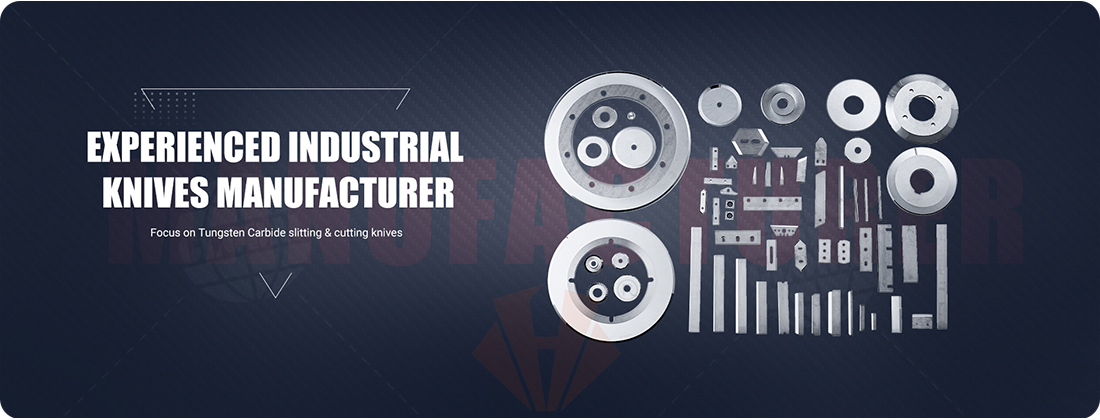

CHENGDU HUAXIN SAMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oa lihlahisoa tsa carbide tsa tungsten, tse kang lithipa tsa carbide tse kenngoang bakeng sa ho betla lehong, lithipa tse chitja tsa carbide bakeng sa ho seha lithupa tsa sefe ea koae le sakerete, lithipa tse chitja bakeng sa ho seha khateboto e nang le corugat, mahare a lehare a masoba a mararo/mahare a nang le masoba bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lihlahisoa tsa li-blade tsa indasteri tsa tungsten carbide tse sebetsang hantle haholo

Tšebeletso e Ikhethileng

Huaxin Cemented Carbide e etsa di-blade tsa tungsten carbide tse ikgethileng, di-blank tse fetotsweng tse tloaelehileng le tse tloaelehileng le di-preform, ho qala ka phofo ho isa di-blank tse fedisitsweng. Kgetho ya rona e felletseng ya dikereiti le tshebetso ya rona ya tlhahiso e fana ka disebediswa tse sebetsang hantle, tse tshepahalang tse bopehileng jwalo ka netweke tse sebetsanang le diphephetso tse ikgethang tsa tshebediso ya bareki diindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Mphalane-11-2025