Ka hare hoindasteri ea masela, ho nepahala, ho tšoarella, le bokgoni ke tsa bohlokwa. Har'a disebediswa tse fapaneng tse sebediswang, mahare a tungsten carbide a hlahile e le phetoho e kgolo ka lebaka la thepa ya ona e phahameng. Sengolwa sena se hlahloba tshebediso ya mahare a tungsten carbide masela, melemo ya ona, mesebetsi e itseng, le temohisiso mabapi le sekgahla sa ona sa ho nkela sebaka.

Likopo Indastering ea Masela

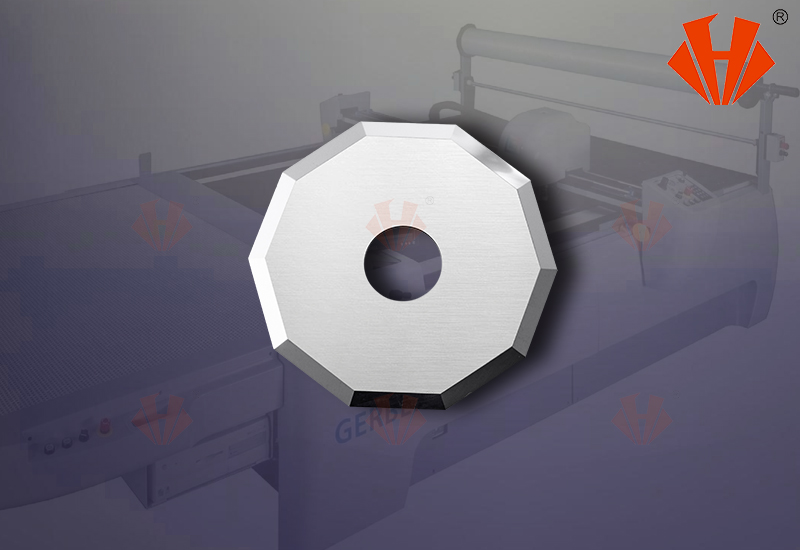

Mahare a carbide ea Tungstenli sebelisoa haholo lits'ebetsong tse 'maloa lefapheng la masela:

- Ho Seha Masela: Bakeng sa ho seha masela a mangata, ho tloha ho silika e bonolo ho isa ho denim e thata, mahare a tungsten carbide a ratoa ka lebaka la ho ba bohale le ho phela nako e telele. A sebelisoa lisebelisoa tsa ho seha ka letsoho le mechining ea ho seha e iketsang.

- Mesebetsi ea ho Seha: Tlhahisong ea litheipi, liribone, kapa masela afe kapa afe a masesaane, mahare ana a bohlokoa bakeng sa lits'ebetso tsa ho seha moo ho hlokahalang ho nepahala ho boloka bophara bo tsitsitseng.

- Mechini ea ho kuta: Mechini ea ho kuta e nang le mahare a tungsten carbide e sebelisetsoa ho kuta, ho bopa le ho qeta masela, ho netefatsa hore a sehiloe hantle ntle le ho taboha kapa ho senya thepa.

- Ho Daea le ho Qetella: Mahare a boetse a sebelisoa lits'ebetsong tse kang ho seha masela a dailoeng kapa mathoko a ho qetela, moo ho tšoarellang tlas'a maemo a metsi ho hlokahalang.

Melemo ea Li-blade tsa Tungsten Carbide

Li-blade tsa tungsten carbide li fana ka melemo e 'maloa e etsang hore li be ntle bakeng sa ts'ebeliso ea masela:

- Bothata bo Ikhethang: Ka tekanyo ea bothata e tšoanang le ea daemane, mahare ana a boloka bohale ka nako e telele, e leng se hlokahalang bakeng sa ho seha lesela la limithara tse likete ntle le ho fifala.

- Ho Tšoarella: Li hanela ho tsofala le ho taboha, li fokotsa makhetlo a liphetoho tsa lehare le nako e amanang le ho se sebetse, ka hona li eketsa katleho ea ts'ebetso.

- Ho nepahala: Mahare a fana ka ho seha ho hloekileng le ho nepahetseng, e leng habohlokoa ho boloka boleng ba masela a boleng bo holimo.

- Khanyetso ea Mocheso le Lik'hemik'hale: Carbide ea Tungsten e ka mamella mocheso o phahameng le ho pepesehela lik'hemik'hale hangata ho kopanang le ts'ebetso ea masela, e leng se fokotsang ho senyeha ha lehare.

- Ho Sebetsa ka Theko e Tlase: Le hoja qalong di bitsa tjhelete e ngata ho feta mahare a tshepe, nako ya tsona ya ho phela nako e telele e fana ka poloko e kgolo ha nako e ntse e ya ka lebaka la ho se nkelwe sebaka kgafetsa.

Karolo ea Li-blade tsa Tungsten Carbide

Karolo e ka sehloohong ea mahare a tungsten carbide masela ke ho netefatsa hore ho na le ho seha ha boleng bo holimo ho ntlafatsang boleng ba sehlahisoa le ho fokotsa litšila.

- Ntlafatsa Bokgoni ba ho Seha: Ka ho boloka bohale, li lumella lebelo le potlakileng la ho seha ntle le ho senya ho nepahala.

- Fokotsa Litšila tsa Thepa: Ho seha ka nepo ho fokotsa litšila tsa masela, e leng se thusang moruong le tikolohong.

- Tšehetso ea Boiketsetso: Mechini e mengata ea seha masela ea sejoale-joale e etselitsoe ho sebetsa ka mahare ana, e tšehetsang boiketsetso bakeng sa tlhahiso e tsitsitseng le e phahameng.

Sekhahla sa Phetolo le Tlhokomelo

Hammoho le tsoelo-pele ea thepa, lisebelisoa tsa ho seha carbide ea tungsten tse thata haholo le tsona li hloka tsebo e phahameng kaha, ho sa tsotelehe hore na thepa ea carbide ea tungsten e ntle hakae, e tlameha ho ba betere ha tsebo e khotsofatsa litlhoko. Litlhoko tsa tlhahiso, mohlala, li etsa hore ho be thata ho khutlisa bothata ba pele ba carbide ea tungsten ea boleng bo holimo ka mor'a ho senyeha ka lebaka la mocheso o phahameng le ho hloleha ha moetsi ho etsa thepa. Ho na le libaka tse 'maloa tse chesang tse sebelisoang lits'ebetsong tsa ho bopa le ho tjheseletsa tse sebelisoang ho etsa lisebelisoa tsena. Ntle le theknoloji e tsoetseng pele, mocheso o phahameng o tla etsa hore ntho ea carbide ea tungsten e senyehe.

- Sekhahla sa Phetoho: Sekhahla sa ho nkela sebaka ha mahare a tungsten carbide masela se fapana ho latela matla a tshebediso, empa hangata a nka nako e telele ho feta a tshepe ka tekanyo e kgolo, hangata ka makgetlo a 50 ho isa ho a 500 mabapi le nako ya ho tsofala.

- Tlhokomelo le ho Lokisa: Ho fapana le tšepe, mahare a tungsten carbide a hloka lisebelisoa tse khethehileng tsa ho lokisa ka lebaka la ho ba thata haholo. Leha a ka lokisoa bocha, hangata ho theko e tlase ho a nkela sebaka ka mor'a tšebeliso e kholo hobane ho lokisa bocha ho kanna ha se ke ha khutlisa bohale ba pele boemong bo tšoanang.

- Matšoao a ho Nkela Sebaka: Mahare a lokela ho nkeloa sebaka ha a bontša matšoao a ho taboha, ho tsofala ho feteletseng, kapa ha boleng ba ho seha bo fokotseha ka ho hlaka. Basebelisi ba hloka ho beha leihlo ts'ebetso ea lehare haufi-ufi, haholo-holo libakeng tse nang le molumo o mongata.

Mahare a carbide ea Tungstenba fetotse ts'ebetso ea ho seha indastering ea masela, ba fana ka ho tšoarella le ho nepahala ho sa bapisoeng. Karolo ea bona e feta ho seha feela; ba bohlokoa ho ntlafatseng tlhahiso, ho fokotsa litšenyehelo, le ho netefatsa boleng bo phahameng ba lihlahisoa tsa masela. Leha letsete la pele le ka ba holimo, melemo ea nako e telele mabapi le ho fokotseha ha makhetlo a ho nkeloa sebaka le tlhokomelo e ba etsa khetho e bohlale bakeng sa bahlahisi ba masela ba ikemiselitseng ho sebetsa hantle le bokhabane tlhahisong. Kakaretso ena e totobatsa hore na ke hobane'ng ha tungsten carbide e fetohile thepa ea bohlokoa tlhahisong ea masela ea sejoale-joale, e totobatsa karolo ea eona ho sutumelletseng meeli ea se ka khonehang ts'ebetsong ea masela.

Huaxin Samente Carbide(https://www.huaxincarbide.com)e etsa di-blade tsa tungsten carbide tse ikgethileng, tse fetotsweng tse tloaelehileng le tse tloaelehileng le di-preform, ho qala ka phofo ho isa ho di-blank tse fedisitsweng. Kgetho ya rona e felletseng ya dikereiti le tshebetso ya rona ya tlhahiso e fana ka disebediswa tse sebetsang hantle, tse tshepahalang tse bopehileng jwalo ka netweke tse sebetsanang le diphephetso tse ikgethang tsa tshebediso ya bareki diindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

Mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

Contact us: lisa@hx-carbide.com

Mohala le WhatsApp: 86-18109062158

Nako ea poso: Pherekhong-20-2025