Ho Utloisisa Lithipa tsa Phetoho le Melemo ea Tsona Liindastering tse Fapaneng

Lithipa tsa Phetoho ke Eng?

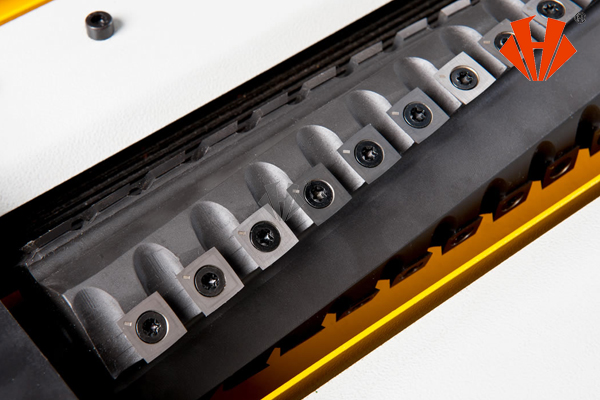

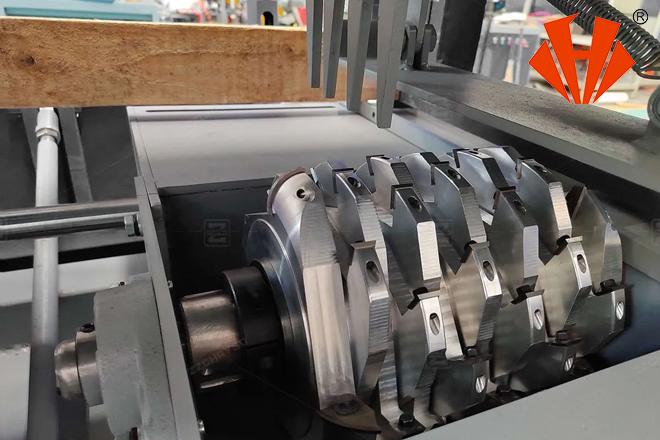

Lithipa tsa ho fetola ke lisebelisoa tsa ho seha tse nang le mahlakore a mabeli, tse li lumellang ho fetoloa bakeng sa tšebeliso e telele. Tshebetso ena ea mahlakore a mabeli ke tšobotsi ea bohlokoa e ntlafatsang bophelo ba sesebelisoa le katleho ea sona, e fokotsang nako ea ho se sebetse le litšenyehelo tsa ho se nkela sebaka. Lithipa tsena li sebelisoa haholo lisebelisoa tse kang li-grooving cutterheads, li-table shaper, le mechini ea ho betla mahlakore, moo ho seha ka nepo le ho phela nako e telele e leng tsa bohlokoa.

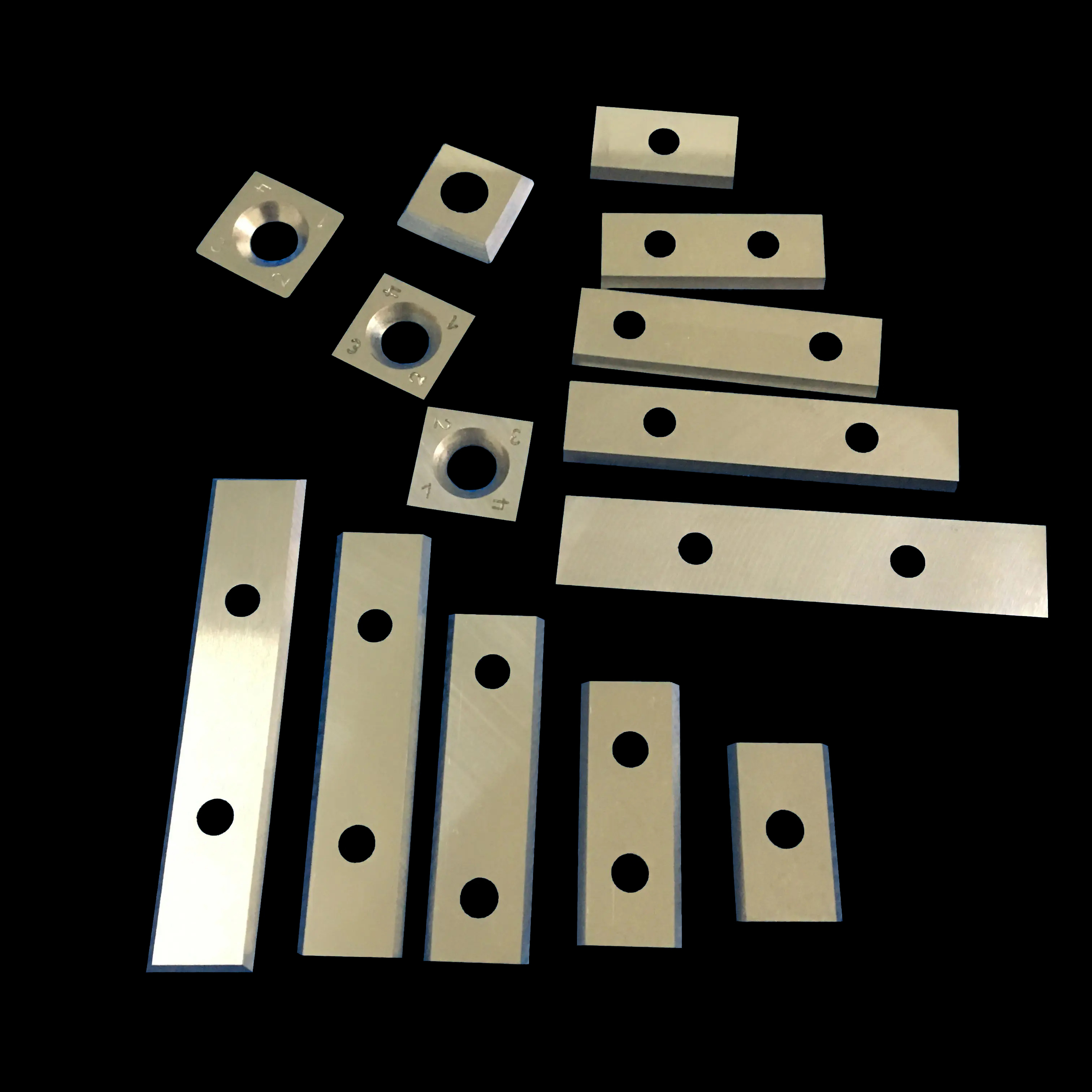

Li-blade tse ka fetoloang tsa Carbide le Melemo ea tsona

Mahare a ka fetoloang a carbide ke khetho e tsebahalang bakeng sa lithipa tse fetohang ka lebaka la ts'ebetso ea tsona e ikhethang le ho boloka litšenyehelo li le tlase. Molemo o moholo oa mahare a ka fetoloang ke hore a ka phetoa hang ha lehlakore le leng le tsofala, e leng se eketsang nako ea ts'ebeliso ea thipa habeli. E entsoe ka carbide e sebetsang hantle, mahare ana a hanela ho tsofala haholo 'me a ka mamella lits'ebetso tsa ho seha ka lebelo le phahameng. Sena se etsa hore a be a loketseng liindasteri tse kang ho betla mapolanka, moo ho nkeloa sebaka ha lisebelisoa khafetsa ho ka lebisang ho se sebetseng ho hoholo.

Li-Insert tse ka baloang ka Carbide le Karolo ea tsona ho Lithipa tsa Phetoho

Li-insert tse ka sebelisoang ho lekanya lik'habohaedreite ke tšobotsi e 'ngoe e tloaelehileng lithipeng tse fetohang, haholo-holo mosebetsing oa lehong le oa tšepe. Li-insert tsena li etselitsoe ho nkeloa sebaka ka bonngoe ha li fetoha tse bosootho, ho e-na le ho nkela lehare lohle sebaka. Molemo oa bohlokoa oa li-insert tsa lik'habohaedreite ke bokhoni ba tsona ba ho boloka bohale bo bohale ka nako e telele, esita le tlas'a tšebeliso e boima. Ho fapanyetsana ha li-insert ho lumella liphetoho tse potlakileng le tse bonolo tsa lehare, ho etsa hore tlhokomelo e sebetse hantle le ho fokotsa litšenyehelo tsa ts'ebetso.

Tšebeliso ea li-insert tse ka tsamaisoang ka carbide e boetse e netefatsa boemo bo phahameng ba ho seha ka nepo, kaha li-insert li entsoe ka nepo hore li lekane hantle ka har'a sets'oants'o sa thipa. Ho phaella moo, li fumaneha ka li-geometri tse fapaneng, e leng se lumellang ho fetoloa ho latela litlhoko tse ikhethileng tsa ho seha tsa ts'ebeliso.

Lithipa tsa ho Fetola Khabide e Tiileng

Bakeng sa lits'ebetso tse hlokang boemo bo phahameng ka ho fetisisa ba ho tšoarella le ho nepahala ha ho seha,lithipa tse tiileng tsa ho fetola khabideHangata ke khetho e ratoang. Lithipa tsena li entsoe ka thepa ea carbide ka botlalo, li fana ka thata le ho hanyetsa ho tsofala ha li bapisoa le lithipa tsa tšepe tse tloaelehileng. Lithipa tse tiileng tsa ho fetola li-carbide li ipabola mesebetsing e nepahetseng haholo joalo ka ho thiba, ho bopa le ho kuta, moo bohale bo bohale le bo tsitsitseng bo leng bohlokoa.

Lithipa tsena li sebetsa hantle haholo indastering e kang tlhahiso ea thepa ea ka tlung, moo ho hlokahalang ho seha lintho tse rarahaneng le tse bonolo thepa e kang lehong le mapolanka a laminated. Lithipa tse tiileng tsa carbide li ka mamella khatello ea mesebetsi ena ntle le ho fifala kapele, ho netefatsa hore tlhahiso e lula e sebetsa hantle.

Hangata lithipa tsena li etsoa ka thepa e tšoarellang joalo kakhabidekapatšepe e lebelo le phahameng(HSS), moo carbide e ratoang haholo ka lebaka la ho thatafala ha eona le ho hanyetsa ho tsofala ha eona. Mosebetsing oa lehong, lithipa tsa ho phetholla li sebelisoa mechineng ea ho phunya, ho kopanya le ho sila, moo li thusang ho boloka ho seha ho nepahetseng le ho hloekisa mefuta e fapaneng ea lehong. Ho feta moo,lithipa tse ka fetoloang tsa carbideli ananeloa haholo ka lebaka la bokhoni ba tsona ba ho sebetsana le mapolanka a thata ntle le ho fifala kapele joaloka lithipa tsa tšepe tsa setso.

Lithipa tse apereng carbide tse telele tse 14.6x14.6x2.5mm lia fanoa bakeng sa mechini ea planer le jointer e nang le spiral helical cutterhead, mochini oa planer sander, groover, moulder cutterhead le lits'ebetso tse ling tsa ho betla mapolanka.

Ka kakaretso, lithipa tsa ho retoloha ke tharollo e sebetsang le e theko e tlase indastering e hlokang lisebelisoa tsa ho seha tse nepahetseng haholo le tse tšoarellang nako e telele.

Lithipa tsa Grooving Turnover le Lithipa tsa Grooving Carbide Insert

E 'ngoe ea lits'ebetso tse tloaelehileng haholo bakeng sa lithipa tsa ho fetola lintho ke ho li-grooving cutterheads.Lithipa tsa ho fetola groovingli etselitsoe ka ho khetheha ho seha li-groove hore e be thepa, e leng se etsang hore li be ntle bakeng sa lits'ebetso tse kang ho kopanya, ho etsa liphanele le ho seha lehong le khabisitsoeng. Lithipa tsena li fumaneha ka meralo e fapaneng, ho kenyeletsoalithipa tsa ho kenya kharbidetse kopanyang melemo ea ho tšoarella ha carbide le ho tenyetseha ha lintho tse kenngoang tse ka nkeloang sebaka.

Lithipa tsa ho kenya carbide tse kobehilengli fana ka mekhoa e fapaneng le ts'ebetso e tšoarellang nako e telele, kaha li ka nkeloa sebaka habonolo ka li-insert tse ncha ha li se li tsofetse, ntle le tlhoko ea ho nkela thipa eohle sebaka. Tšobotsi ena e li etsa tharollo e theko e tlaase bakeng sa liindasteri tse nang le litlhoko tse phahameng tsa tlhahiso.

Lithipa tsa Phetoho tsa Tungsten Carbide Tipped (TCT)

Libakeng tse itseng tse fokotsang tlhoko e kholo,Lithipa tsa ho fetola tse nang le Tungsten Carbide Tipped (TCT)di sebediswa. Dithipa tsa TCT di kopanya ho tiya ha lehare la tshepe le ho hanyetsa ho tsofala le ho thatafala ha tungsten carbide, e leng se etsang hore di lokele ho seha thepa e thata jwalo ka lehong le thata le dikompositi.Lithipa tsa ho fetola chelete tsa TCTe fana ka tshebetso e phahameng ya ho seha, haholoholo ditshebedisong tse kang ho bopa lehong, ho qeta ka mathoko, le ho sebetsana le veneer.

Tšebeliso eaLithipa tsa Phetoho ea Tungsten Carbidelits'ebetsong tsena ho netefatsa bophelo bo bolelele ba lisebelisoa, e leng ntho ea bohlokoa haholo indastering moo tlhahiso le katleho li leng bohlokoa. Ka ho fana ka linako tse telele tsa tšebeletso lipakeng tsa liphetoho tsa lisebelisoa, lithipa tsa phetoho ea TCT li kenya letsoho ho fokotseng litšenyehelo tsa ts'ebetso ha nako e ntse e ea.

Lithipa tsa ho Fetola Carbide tse nang le Meeli e 'Meli le tse nang le Meeli e Mengata

Lithipa tsa carbide tse nang le mahlakore a mabelileli-carbide tse nang le mahlakore a mangatake moralo o mong o mocha bakeng sa lithipa tsa ho fetola. Lithipa tsena li na le mahlakore a mangata a ho seha, joalo kaLithipa tse 4 tsa ho fetola or lithipa tsa ho fetola radius, e lumellang bophelo le katleho e kholoanyane ea lisebelisoa. Ha ntlha e 'ngoe e fetoha e lerootho, basebetsi ba ka potoloha thipa feela ho sebelisa ntlha e latelang e bohale. Moralo ona o fokotsa nako ea ho sebetsa haholo 'me o eketsa tlhahiso ka kakaretso.

Bakeng sa lits'ebetso tse hlokang li-geometri tse rarahaneng tsa ho seha,lithipa tsa ho fetola radiusfana ka ho nepahala mesebetsing e kenyeletsang ho seha ho kobehileng kapa ho sekameng. Lithipa tsena li ka boloka boleng bo tsitsitseng ba ho seha le ho thusa ho netefatsa hore sehlahisoa se felileng se boreleli ebile se nepahetse.

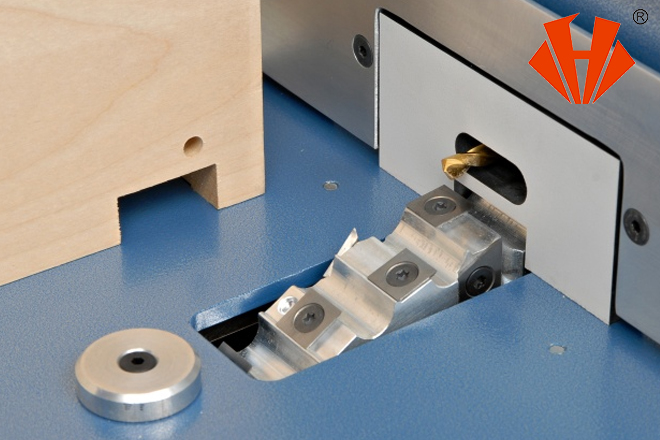

Lithipa bakeng sa Li-Shaper tsa Tafole le Edgebanding

Ntle le tšebeliso ea tsona ho grooving le ho bopa, lithipa tsa ho fetola le tsona li bohlokoa mechineng e kanglibopeho tsa tafolelelisebelisoa tsa ho tlama mathōko. Kenya malebela a khabide bakeng sa ho betla lehongli na le thuso haholo-holo libakeng tsena, moo lithipa li lokelang ho fana ka likotoana tse tsitsitseng le tse boreleli likotoana tsa lehong le mathōkong.Lithipa tsa ho kenya tse nang le thipa e ka thoko, tse sebelisoang mechineng e sebelisang mapheo a sireletsang thepa ea ka tlung kapa likhabineteng, li etselitsoe ho fana ka qetello e se nang sekoli ha ka nako e ts'oanang li netefatsa hore mapheo a ho seha a lula a le bohale nakong eohle ea ho matha nako e telele.

Lithipa tsa ho Fetola Carbide tse nang le Meeli e 'Meli le tse nang le Meeli e Mengata

Lithipa tsa carbide tse nang le mahlakore a mabelileli-carbide tse nang le mahlakore a mangatake moralo o mong o mocha bakeng sa lithipa tsa ho fetola. Lithipa tsena li na le mahlakore a mangata a ho seha, joalo kaLithipa tse 4 tsa ho fetola or lithipa tsa ho fetola radius, e lumellang bophelo le katleho e kholoanyane ea lisebelisoa. Ha ntlha e 'ngoe e fetoha e lerootho, basebetsi ba ka potoloha thipa feela ho sebelisa ntlha e latelang e bohale. Moralo ona o fokotsa nako ea ho sebetsa haholo 'me o eketsa tlhahiso ka kakaretso.

Bakeng sa lits'ebetso tse hlokang li-geometri tse rarahaneng tsa ho seha,lithipa tsa ho fetola radiusfana ka ho nepahala mesebetsing e kenyeletsang ho seha ho kobehileng kapa ho sekameng. Lithipa tsena li ka boloka boleng bo tsitsitseng ba ho seha le ho thusa ho netefatsa hore sehlahisoa se felileng se boreleli ebile se nepahetse.

Lithipa bakeng sa Li-Shaper tsa Tafole le Edgebanding

Ntle le tšebeliso ea tsona ho grooving le ho bopa, lithipa tsa ho fetola le tsona li bohlokoa mechineng e kanglibopeho tsa tafolelelisebelisoa tsa ho tlama mathōko. Kenya malebela a khabide bakeng sa ho betla lehongli na le thuso haholo-holo libakeng tsena, moo lithipa li lokelang ho fana ka likotoana tse tsitsitseng le tse boreleli likotoana tsa lehong le mathōkong.Lithipa tsa ho kenya tse nang le thipa e ka thoko, tse sebelisoang mechineng e sebelisang mapheo a sireletsang thepa ea ka tlung kapa likhabineteng, li etselitsoe ho fana ka qetello e se nang sekoli ha ka nako e ts'oanang li netefatsa hore mapheo a ho seha a lula a le bohale nakong eohle ea ho matha nako e telele.

Huaxin Carbide: E Etellang Pele Indasteri Tlhahisong ea Lithipa tsa Phetoho

Moetsi e mong ea hlahelletseng oa lithipa tsa boleng bo holimo tsa ho fetola lintho keHuaxin Carbide, k'hamphani ea Chaena e ikhethang tlhahisong ea lisebelisoa tsa carbide bakeng sa ts'ebeliso ea ho betla lehong le tšepe. E tsebahala ka lihlahisoa tsa eona tse nepahetseng le tse sebetsang hantle, Huaxin Carbide e hlahisa mefuta e mengata ea lithipa tsa ho fetola, ho kenyeletsoalithipa tse tiileng tsa ho fetola khabide, Lithipa tsa phetoho tse nang le lintlha tsa Tungsten carbidelelithipa tsa ho kenya khabide tse groovingKa ho tsepamisa maikutlo ho tšoarelleng le ho nepahala ha ho seha, Huaxin Carbide e se e le mofani ea tšepahalang oa liindasteri tse hlokang lisebelisoa tsa ho seha tsa boleng bo holimo bakeng sa ts'ebetso ea tsona.

Lithipa tsa ho fetola, haholo-holo tse entsoeng ka thepa ea carbide le tungsten carbide, li fana ka ts'ebetso e phahameng le bophelo bo bolelele ba lisebelisoa. Ebang li sebelisoa mesebetsing ea ho betla lehong, ho betla tšepe, kapa lits'ebetsong tse ling tsa tlhahiso, lithipa tsena li fana ka litharollo tse theko e tlaase le tse sebetsang hantle bakeng sa ho seha ka nepo.mahare a ka fetoloang, li-insert tse ka kenyelletsoanglelithipa tse nang le mahlakore a mabelie etsa hore e be ea bohlokoa haholo libakeng tse nang le bongata bo bongata. Bahlahisi ba joalo kaHuaxin Carbideli etella pele ho faneng ka lisebelisoa tsena tse tsoetseng pele, ho netefatsa hore liindasteri lefatšeng ka bophara li ka fihlela litlhoko tsa tsona tsa tlhahiso ha li ntse li boloka boleng le katleho.

Nako ea poso: Pulungoana-13-2024