Khanyetso e ikhethang ea ho roala eamahare a tungsten carbide, leha e le e phahameng ho feta boholo ba lisebelisoa tse ling tsa ho seha, leha ho le joalo e ka senyeha butle-butle ka mekhoa e mengata e ts'oanang ha e sebelisoa khafetsa ka nako e telele. Ho utloisisa lits'ebetso tsena tsa ho tsofala ho bohlokoa bakeng sa ho nts'etsapele mekhoa e sebetsang ea ho thibela le ho ntlafatsa ts'ebetso ea lehare lits'ebetsong tsa indasteri.

1. Ho roala ka mokhoa o sa hlakang

Ho robeha ha moriri ho emela e 'ngoe ea mekhoa e tloaelehileng le ea bohlokoa ea ho robeha e amangmahare a tungsten carbidets'ebetsong e tsoelang pele. Ts'ebetso ena e etsahala ha lintho tse thata tse kenyellelitsoeng kapa likaroloana tse thatafalitsoeng ka har'a thepa ea mosebetsi li sebelisana ka mokhoa oa mechini le bokaholimo ba lehare, e leng se lebisang ho tlosoeng ha thepa butle-butle ka liketso tsa ho seha le ho lema tse nyane.lithollo tsa tungsten carbidee fana ka khanyetso e kholo ho mokhoa ona oa ho robeha, empa karolo ea cobalt binder e bonolo haholo e kotsing ea ho hohloka, e leng se ka lebisang ho hlaheng ha lithollo tsa WC le ho robeha ha tsona kapa ho huloa ha tsona ka mor'a moo. Lipatlisiso li bontša hore ho robeha ha ho hohloka ho atile haholo ha ho etsoa lisebelisoa tse nang le metsoako e hohlokang joalo ka li-alloy tsa silicon-aluminium, thepa e kopaneng, kapa likarolo tsa mosebetsi tse nang le sekala sa bokaholimo bo tiileng.

Sekhahla sa ho robeha ha khohlela se susumetsoa ke mabaka a 'maloa, ho kenyeletsoa boholo le sebopeho sa likaroloana tse robehang, litšobotsi tsa mechini tsa mosebetsi le thepa ea lehare, le maemo a ho seha a sebelisitsoeng. Litlhahlobo tsa indasteri li tiisa hore ho robeha ha khohlela hangata ho iponahatsa e le ho robeha ka mokhoa o ts'oanang ha sefahleho sa lehlakore la sesebelisoa kapa ho thehoa ha li-groove holim'a bokaholimo ba ho ikopanya le chip, ka sekhahla sa ho robeha se amanang ka kotloloho le sebaka sa ho seha le ka tsela e fapaneng le ho thatafala ha ho seha.

2. Ho apara ho Fapaneng

Ho senyeha ha ho hasanya, ho tsejoang hape e le ho senyeha ha ho qhibiliha le ho hasana, ho ba bohlokoa haholo lits'ebetsong tsa ho sebetsa ka mocheso o phahameng moo mocheso oa ho seha o fetang 800°C. Maemong ana a phahameng a mocheso, likarolo tsa lik'hemik'hale tsa lehare la carbide ea tungsten le thepa ea mosebetsi li fetoha tse tsamaeang haholo, e leng se lebisang ho hasaneng ho kopaneng ho pholletsa le sebopeho sa sesebelisoa le mosebetsi. Ketsahalo ena e hlahella haholo ha ho sebetsoa thepa ea ferrous, moo tšepe e tsoang mosebetsing e ka hasanang lehare la carbide ha carbon, tungsten le cobalt tse tsoang lehareng li hasana le thepa ea chip.

Ts'ebetso ea ho hasana e fetola sebopeho le thepa ea likarolo tse kaholimo tsa lehare. Ha liathomo tsa khabone li falla ho tloha holim'a lehare, likristale tsa WC lia senyeha, e leng se lebisang phokotsong ea ho tiea ka kakaretso le botšepehi ba mechini. Ka nako e le 'ngoe, ho hasana ha cobalt ho fokolisa tlamo pakeng tsa lithollo tsa carbide tsa tungsten, e leng se behang botsitso ba sebopeho sa lehare kotsing. Ho senyeha hona ha lik'hemik'hale hangata ho fella ka ho thehoa ha ho tsofala ha crater sefahlehong sa rake ea sesebelisoa, 'me botebo bo phahameng ba ho tsofala bo etsahala sebakeng sa mocheso o phahameng ka ho fetisisa. Lithuto li bontšitse hore ho kenyelletsa titanium carbide (TiC) ka har'a motsoako oa tungsten carbide ho ka fokotsa haholo ho tsofala ha ho hasanya ka lebaka la coefficient e tlase ea ho hasanya ha TiC ha e bapisoa le WC le bokhoni ba eona ba ho theha likarolo tse sireletsang tsa titanium oxide mochesong o phahameng.

3. Ho Koaheloa ke Sekhomaretsi le Lik'hemik'hale

Ho tsofala ha sekhomaretsi ho etsahala ha dikotwana tse nyane haholo tsa thepa ya mosebetsi di kopanngwa le bokahodimo ba lehare tlasa tshusumetso e kopaneng ya kgatello e phahameng le mocheso sebopehong sa sesebediswa le mosebetsi. Dikotwana tsena tsa sekhomaretsi di ka robeha hamorao nakong ya motsamao o amanang, e leng se lebisang ho tlosweng ha dikarolwana tse nyane bokahodimong ba lehare. Mokgwa ona o atile haholo ha ho sebetswa thepa e ductile e nang le tshekamelo ya ho kgomarelalisebelisoa tsa ho seha, joalo ka litšepe tse kopantsoeng tsa aluminium kapa litšepe tse itseng tse sa hloekang.

Ka nako e ts'oanang, lits'ebetso tsa ho tsofala ha lik'hemik'hale, ho kenyeletsoa le oxidation le liketso tse ling tsa thermochemical, li ka kenya letsoho haholo ho senyeheng ha lehare, haholo-holo libakeng tse nang le mocheso o phahameng.Carbide ea Tungstene ka oxidation ho etsa tungsten oxide le carbon dioxide mochesong o fetang 600°C, ha thepa ea cobalt binder e ka angoa ke oxidation ka mokhoa o ts'oanang, e leng se ka lebisang ho qhalaneng ha karolo ea binder ea lehare le tahlehelo e latelang ea lithollo tsa tungsten carbide. Boteng ba likarolo tse itseng tsa lik'hemik'hale linthong tsa mosebetsi, joalo ka chlorine kapa sebabole liallong tse ling, bo ka potlakisa lits'ebetso tsena tsa ho tsofala ha lik'hemik'hale ka ho thehoa ha lihlahisoa tsa karabelo tse feto-fetohang kapa tse matla a tlase.

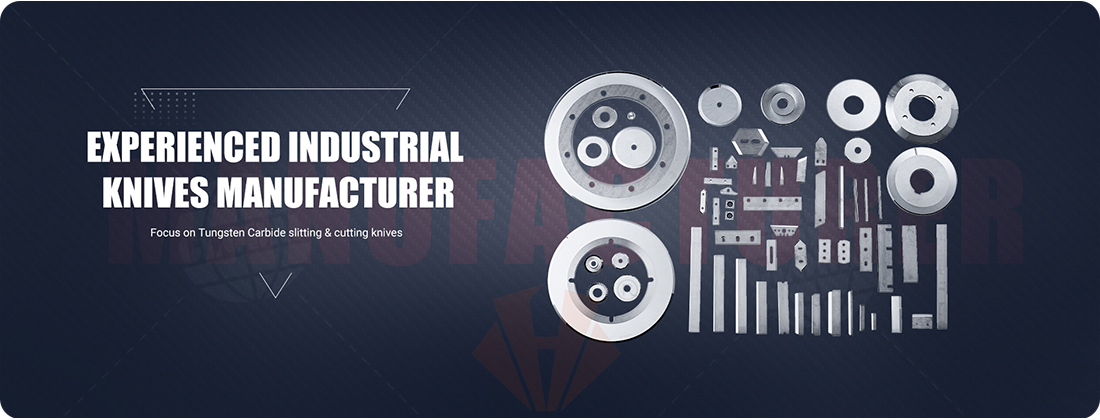

Mabapi le Huaxin: Moetsi oa Lithipa tsa ho Senya tsa Tungsten Carbide tse samentetsoeng

CHENGDU HUAXIN SAMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oa lihlahisoa tsa carbide tsa tungsten, tse kang lithipa tsa carbide tse kenngoang bakeng sa ho betla lehong, lithipa tse chitja tsa carbide bakeng sa ho seha lithupa tsa sefe ea koae le sakerete, lithipa tse chitja bakeng sa ho seha khateboto e nang le corugat, mahare a lehare a masoba a mararo/mahare a nang le masoba bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

Lihlahisoa tsa li-blade tsa indasteri tsa tungsten carbide tse sebetsang hantle haholo

Tšebeletso e Ikhethileng

Huaxin Cemented Carbide e etsa di-blade tsa tungsten carbide tse ikgethileng, di-blank tse fetotsweng tse tloaelehileng le tse tloaelehileng le di-preform, ho qala ka phofo ho isa di-blank tse fedisitsweng. Kgetho ya rona e felletseng ya dikereiti le tshebetso ya rona ya tlhahiso e fana ka disebediswa tse sebetsang hantle, tse tshepahalang tse bopehileng jwalo ka netweke tse sebetsanang le diphephetso tse ikgethang tsa tshebediso ya bareki diindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Mphalane-24-2025