Lisebelisoa tsa mahare a tungsten carbide mosebetsing oa ho betla mapolanka ke life? Ke mahare afe a tungsten carbide ao u lokelang ho a khetha pele?

Lisebelisoa tsaLi-blades tsa Tungsten Carbide: Mahare a carbide ea Tungsten Haholo-holo li entsoe ka tungsten carbide, e leng motsoako o entsoeng ka tungsten le carbon. Thepa ena e tsebahala ka thata ba eona bo ikhethang, hangata e lekantsoe ka thata ba 9.0 sekaleng sa Mohs, joalo ka daemane. Ts'ebetso ea tlhahiso e kenyelletsa ho kopanya phofo ea tungsten le phofo ea carbon, ebe ho silafatsoa motsoako ona mochesong o phahameng ho etsa carbide. Lits'ebetsong tse ling, tungsten carbide e ntlafatsoa le ho feta ka cobalt e le binder, e thusang ho fihlela tekano pakeng tsa thatafalo le ho tiea. Boleng ba cobalt bo ka fapana, bo ama khanyetso ea lehare le ho hanyetsa ho tsofala.

Tmahare a carbide a ungstenLi entsoe haholo-holo ka tungsten carbide (WC), e leng motsoako oa tungsten le carbon. Thepa ena e tsebahala ka ho thatafala ha eona, ho hanyetsa ho tsofala le ho tšoarella ha eona, e leng se etsang hore e be e loketseng ho sebelisoa lisebelisoa tsa ho seha, ho kenyeletsoa le mahare a ho betla lehong.

Lisebelisoa tsa Bohlokoa ho Tungsten Carbide Blades:

Tungsten Carbide (WC): Karolo ea bohlokoa, e fanang ka thata e ikhethang le ho hanyetsa ho tsofala.

Cobalt (Co): Hangata e sebelisoa e le sehokelo ho tšoara likaroloana tsa carbide hammoho, ho ntlafatsa ho tiea le ho hanyetsa tšusumetso.

Nikele (Ni): Ka linako tse ling e sebelisoa ho ntlafatsa ho hanyetsa ho bola.

Titanium kapa likarolo tse ling tsa ho kopanya: Maemong a mang, likarolo tse ling li ka eketsoa ho ntlafatsa litšobotsi tse itseng, joalo ka botsitso ba mocheso.

Mahare a Tungsten Carbide bakeng sa ho Sebetsa ka Lehong:

Ha o kgetha di-blade tsa tungsten carbide bakeng sa ho betla lehong, dintlha tse latelang di lokela ho o tataisa qetong ya hao:

Mofuta oa lehare:

Li-planer Blades: Bakeng sa ho batalatsa kapa ho boreletsa libaka tsa lehong, li-planer tsa tungsten carbide tsa boleng bo holimo li fana ka bohale le ts'ebetso e tšoarellang nako e telele.

Lihlooho tsa ho Seha ka Spiral: Tsena li fana ka qetello e boreleli 'me ha li na monyetla oa ho qhekelloa, e leng sa bohlokoa bakeng sa ho etsa mapolanka a boleng bo holimo.

Mahare a Sakha: Mahare a sakha a tungsten carbide a loketse ho rema patsi, plywood le thepa e 'ngoe, kaha a boloka lehlakore le bohale 'me a hanela ho tsofala.

Li-Router Bits: Bakeng sa ho betla mapolanka a matle, li-router bits tse nang le lintlheng tsa carbide lia ratoa ka lebaka la ho boloka mahlakore a tsona hantle le ts'ebetso e boreleli ea ho seha.

Likopo tsa ho Sebetsa ka Lehong:

Lifate tse bonolo: Haeba u sebetsa haholo-holo ka lifate tse bonolo, makhasi a nang le carbide e ntle ea grit a ka ba a lekaneng.

Lifate tse thata: Bakeng sa thepa e teteaneng, e thata, o lokela ho khetha mahare a nang le sebopeho se thata sa carbide, se fanang ka ho tšoarella ho hoholo tlas'a khatello e phahameng ea ho seha.

Khetho ea Pele bakeng sa Li-blade tsa Tungsten Carbide ho Woodworking:

Bakeng sa ho Rala le ho Boreletsa Bokaholimo: Li-blade tsa planer tsa tungsten carbide le lihlooho tsa spiral cutter e lokela ho ba khetho ea hau ea pele, kaha li fana ka bohale bo tšoarellang nako e telele le liphetho tse boreleli.

Bakeng sa ho Seha: Mahare a sakha ea tungsten carbide a loketse ho seha patsi e ngata ka ho se senyeha hanyane, haholo-holo ha ho sebetsanoa le mapolanka a thata kapa thepa e kopaneng.

Ka ho khetha mahare a boleng bo holimo a tungsten carbide a etselitsoeng mesebetsi ea hau e itseng ea ho betla lehong, u'E tla netefatsa hore lisebelisoa tsa hau li sebetsa hantle ebile li phela nako e telele.

Mohlala, mahare a nang le cobalt e ngata (hoo e ka bang 12-15%) a sebediswa bakeng sa ditshebediso tse kenyeletsang meroalo e mahareng ho isa ho e phahameng ya ho thothomela, athe a nang le cobalt e tlase (6-9%) a kgethwa bakeng sa ditshebediso moo bophelo bo bolelele le ho hanyetsa ho tsofala di etelletsweng pele.

Mahare a Tungsten Carbide Tipped (TCT): Bakeng sa ho betla lehong, mahare a TCT hangata a kgothaletswa e le kgetho ya pele ka lebaka la ho tenyetseha ha ona le ho phela nako e telele. Mahare ana a na le meno a tungsten carbide a kopantsweng mmeleng wa tshepe, a kopanyang ho tshwarella le ho hlaka ha carbide le ho tenyetseha ha tshepe. A loketse ho seha mefuta e fapaneng ya thepa ho tloha ho lehong le thata ho isa ho ditshipi le dipolasetiki, a fana ka ho seha ho nepahetseng le ho hlweka. Mahare a TCT a molemo haholo bakeng sa bokgoni ba wona ba ho boloka bohale ba lehlakore nako e telele ho feta mahare a tshepe a lebelo le phahameng (HSS), ho bolelang ho se be le ho hlaka kgafetsa, leha a ka ba theko e boima haholo pele.

Mahare a Tungsten Carbide a Tiileng: Leha di sa tlwaeleha hakaalo ka lebaka la ho robeha ha bonolo le ditjeo, di-blade tse tiileng tsa tungsten carbide e ka ba kgetho e ntle bakeng sa ditshebediso tse itseng, tse kang ho seha thepa e kgopang haholo kapa e thata moo ho boloka mahlakore ho leng bohlokwa. Leha ho le jwalo, ha di kgothaletswe e le kgetho ya pele ka kakaretso ho betleng mapolanka ka lebaka la ho robeha ha tsona le bothata ba ho di leotsa.

Khetho ea Lehare ka Tšebeliso: Ha u khetha lehare la hau la pele la tungsten carbide, nahana ka mofuta oa lehong leo u tla sebetsa le lona. Bakeng sa lifate tse bonolo kapa tsa ho betla lehong ka kakaretso, lehare la TCT le nang le cobalt e mahareng le ka lekana. Bakeng sa lifate tse thata, u ka 'na ua batla ho sheba mahare a nang le li-geometri tse itseng tse etselitsoeng ho tiea, joalo ka tse nang le 40º e kenyelelitsoe lehlakoreng la bohale bakeng sa lits'ebetso tse kenyeletsang meroalo ea ho tšoha.

Fkapa boholo ba basebetsi ba mapolanka ba qalang ka tungsten carbide,Lehare la TCT e tla ba khetho ea pele e sebetsang, e fanang ka tekano lipakeng tsa litšenyehelo, ts'ebetso, le bonolo ba ts'ebeliso mesebetsing e fapaneng ea ho betla mapolanka.

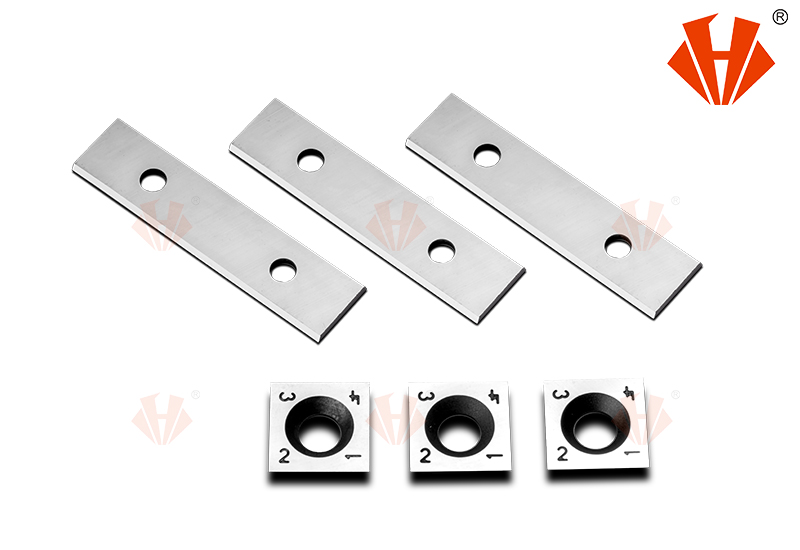

Li-Planer Blades tse ka Khutlisetsoang morao Lithipa li entsoe ka sehlopha sa carbide sa boleng bo holimo 'me li hlahlojoa ka bonngoe ho netefatsa boleng le ho nepahala. Li-planer blades li sebelisoa ha ho sebetsoa holim'a lehong ho thusa ho theha libaka tse reriloeng hantle. Li ka boela tsa sebelisoa ho shapa, le ho lahla mathoko. Boholo ba lehare bo bolela boholo ba planer eo e tla e lekana. E tla tšoarella ho feta mathoko a tloaelehileng a HSS bonyane makhetlo a 20 'me e hlahise qetello e boreleli le e hloekileng.

Huxin Samente Carbide(www.huaxincarbide.com)E shebane le ho sebedisa thepa e tswetseng pele le mekgwa ya tlhahiso ho hlahisa mahare a ipabolang ka ho thatafala, ho hanyetsa ho tsofala le ho ba bohale. Bokgoni ba bona ba theknoloji ya carbide bo ba etsa hore e be molekane ya tshepahalang bakeng sa dikgwebo tse hlokang mahare a carbide a boleng bo hodimo a ho betla lehong.

Ikopanye le rona:lisa@hx-carbide.com

Nako ea poso: Pherekhong-08-2025