Thepa ea motsoako e entsoeng ka motsoako o thata oa tšepe e hanyetsang le tšepe e kopanyang ka mokhoa oa ho sebelisa phofo ea tšepe. Carbide e samente e na le letoto la litšobotsi tse ntle tse kang ho thatafala ho hoholo, ho hanyetsa ho tsofala, matla le ho tiea hantle, ho hanyetsa mocheso le ho hanyetsa ho tsofala, haholo-holo ho thatafala ha eona ho hoholo le ho hanyetsa ho tsofala, tse lulang li sa fetohe esita le mochesong oa 500 °C, e ntse e na le ho thatafala ho hoholo ho 1000 ℃. Carbide e sebelisoa haholo e le thepa ea lisebelisoa, joalo ka lisebelisoa tsa ho reteleha, li-cutter tsa silling, li-planer, li-drill, lisebelisoa tsa ho taboha, jj., bakeng sa ho seha tšepe e entsoeng ka tšepe, litšepe tse seng tsa ferrous, polasetiki, likhoele tsa lik'hemik'hale, graphite, khalase, lejoe le tšepe e tloaelehileng, 'me e ka boela ea sebelisoa bakeng sa ho seha thepa e thata ho sebelisoa mochining joalo ka tšepe e sa cheseng, tšepe e sa ruseng, tšepe e phahameng ea manganese, tšepe ea lisebelisoa, jj. Lebelo la ho seha la lisebelisoa tse ncha tsa carbide joale le feta makhetlo a makholo a tšepe ea carbon.

Tšebeliso ea carbide e entsoeng ka samente

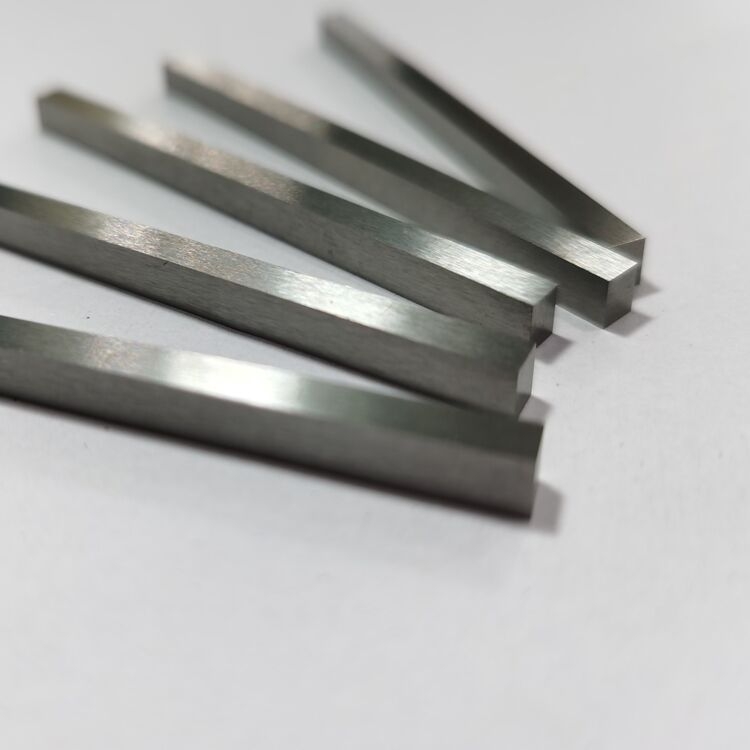

(1) Thepa ea lisebelisoa

Carbide ke palo e kholo ka ho fetisisa ea lisebelisoa tsa lisebelisoa, tse ka sebelisoang ho etsa lisebelisoa tsa ho reteleha, li-cutter tsa ho sila, li-planer, li-drill, jj. Har'a tsona, carbide ea tungsten-cobalt e loketse ts'ebetso e khutšoanyane ea li-chip tsa tšepe ea ferrous le e seng ea ferrous le ts'ebetso ea lisebelisoa tse seng tsa tšepe, tse kang tšepe e sitsitsoeng, koporo e sitsitsoeng, bakelite, jj.; carbide ea tungsten-titanium-cobalt e loketse ts'ebetso ea nako e telele ea litšepe tsa ferrous tse kang tšepe. Ts'ebetso ea chip. Har'a li-alloy tse tšoanang, tse nang le cobalt e ngata li loketse ts'ebetso e thata, 'me tse nang le cobalt e nyane li loketse ho phethoa. Carbide e sitsitsoeng ka samente e sebelisoang ka kakaretso e na le nako e telele ea ts'ebetso ea ts'ebetso ho feta li-carbide tse ling tse sitsitsoeng ka samente bakeng sa lisebelisoa tse thata ho sebelisoa mochini tse kang tšepe e sa hloekang.

(2) Thepa ea hlobo

Carbide e samentetsoeng e sebelisoa haholo bakeng sa li-dies tse sebetsang ka mokhoa o batang tse kang li-dies tse hulang ka mokhoa o batang, li-dies tse batang tse otlang ka mokhoa o batang, li-dies tse ntšang ka mokhoa o batang, le li-dies tse ntšang ka mokhoa o batang tse batang.

Li-carbide cold heading dies lia hlokahala hore li be le matla a ho thula hantle, matla a ho robeha, matla a mokhathala, matla a ho kobeha le matla a ho thula hantle tlas'a maemo a ts'ebetso a ho thula kapa a matla. Hangata ho sebelisoa mefuta e mahareng le e phahameng ea cobalt le e mahareng le e mahoashe ea lithollo, joalo ka YG15C.

Ka kakaretso, kamano pakeng tsa ho hanyetsa ho tsofala le ho tiea ha carbide e samentetsoeng e hanyetsana: keketseho ea ho hanyetsa ho tsofala e tla lebisa ho fokotseheng ha ho tiea, 'me keketseho ea ho tiea e tla lebisa ho fokotseheng ha ho hanyetsa ho tsofala. Ka hona, ha ho khethoa limaraka tsa motsoako, ho hlokahala ho fihlela litlhoko tse itseng tsa ts'ebeliso ho latela ntho ea ts'ebetso le maemo a ts'ebetso ea ts'ebetso.

Haeba sehlopha se khethiloeng se ka peperana le ho senyeha kapele nakong ea tšebeliso, sehlopha se nang le ho tiea ho hoholo se lokela ho khethoa; haeba sehlopha se khethiloeng se ka peperana le ho senyeha pele nakong ea tšebeliso, sehlopha se nang le ho tiea ho hoholo le ho hanyetsa ho tiea ho molemo se lokela ho khethoa. . Lihlopha tse latelang: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Ho tloha ka letsohong le letšehali ho ea ho le letona, ho tiea hoa fokotseha, ho hanyetsa ho tiea hoa fokotseha, 'me ho tiea hoa eketseha; ka lehlakoreng le leng, se fapaneng le seo ke 'nete.

(3) Lisebelisoa tsa ho lekanya le likarolo tse sa tsofaleng

Carbide e sebediswa bakeng sa di-inlays tse sa tsofaleng tsa bokahodimo le dikarolo tsa disebediswa tsa ho lekanya, di-bearing tse nepahetseng tsa di-grinder, di-direct plate le di-guide rod tsa di-grinder tse se nang bohareng, di-lathe tse hodimo le dikarolo tse ding tse sa tsofaleng.

Litšepe tse kopanyang hangata ke litšepe tsa sehlopha sa tšepe, hangata cobalt le nickel.

Ha ho etsoa carbide e samentetsoeng, boholo ba karoloana ea phofo ea thepa e tala e khethiloeng bo pakeng tsa 1 le 2 microns, 'me bohloeki bo holimo haholo. Lisebelisoa tse tala li kopantsoe ho latela karolelano e behiloeng ea motsoako, 'me joala kapa mecha e meng ea litaba e eketsoa ho sila ka metsi ka har'a leloala la bolo le metsi ho etsa hore li tsoakane ka botlalo le ho siloa. Sefa motsoako. Ebe, motsoako o granulated, o hatelloa, 'me o futhumatsoa mochesong o haufi le ntlha ea ho qhibiliha ha tšepe ea binder (1300-1500 °C), karolo e thatafalitsoeng le tšepe ea binder li tla etsa motsoako oa eutectic. Kamora ho pholile, mekhahlelo e thatafalitsoeng e ajoa ka har'a gridi e entsoeng ka tšepe ea bonding 'me e hokahane haufi-ufi ho etsa ntho e tiileng. Bohloko ba carbide e samentetsoeng bo itšetlehile ka litaba tsa karolo e thatafalitsoeng le boholo ba lijo-thollo, ke hore, ha litaba tsa karolo e thatafalitsoeng li le holimo 'me lithollo li le tšesaane, bo thatafala bo ba boholo. Bohloko ba carbide e samentetsoeng bo khethoa ke tšepe ea binder. Ha litaba tsa tšepe ea binder li le holimo, matla a ho flexural a phahame.

Ka 1923, Schlerter oa Jeremane o ile a eketsa cobalt ea 10% ho isa ho 20% ho phofo ea carbide ea tungsten e le binder, 'me a qapa motsoako o mocha oa carbide ea tungsten le cobalt. Bothata bona bo latela daemane feela. Carbide ea pele e entsoeng ka samente. Ha ho sehoa tšepe ka sesebelisoa se entsoeng ka motsoako ona, moeli o ka pele o tla fela kapele, 'me esita le moeli o ka pele o tla petsoha. Ka 1929, Schwarzkov United States o ile a eketsa palo e itseng ea carbide ea tungsten le titanium carbide compound carbides motswakong oa pele, e leng se ileng sa ntlafatsa ts'ebetso ea sesebelisoa ho seheng tšepe. Ena ke katleho e 'ngoe historing ea nts'etsopele ea carbide e ka pele.

Carbide e samentetsoeng e na le letoto la thepa e ntle haholo e kang ho thatafala ho hoholo, ho hanyetsa ho tsofala, matla le ho tiea hantle, ho hanyetsa mocheso le ho hanyetsa ho tsofala, haholo-holo ho thatafala ha eona ho hoholo le ho hanyetsa ho tsofala, tse lulang li sa fetohe esita le mochesong oa 500 °C, li ntse li na le ho thatafala ho hoholo ho 1000 ℃. Carbide e sebelisoa haholo e le thepa ea lisebelisoa, joalo ka lisebelisoa tsa ho reteleha, li-cutter tsa silling, li-planer, li-drill, lisebelisoa tsa ho taboha, jj., bakeng sa ho seha tšepe e entsoeng ka tšepe, litšepe tse seng tsa ferrous, polasetiki, likhoele tsa lik'hemik'hale, graphite, khalase, lejoe le tšepe e tloaelehileng, 'me e ka boela ea sebelisoa bakeng sa ho seha lisebelisoa tse thata ho sebelisoa mochining tse kang tšepe e sa cheseng, tšepe e sa ruseng, tšepe e phahameng ea manganese, tšepe ea lisebelisoa, jj. Lebelo la ho seha la lisebelisoa tse ncha tsa carbide joale le feta makhetlo a makholo a tšepe ea carbon.

Carbide e ka boela ea sebelisoa ho etsa lisebelisoa tsa ho phunya majoe, lisebelisoa tsa merafo, lisebelisoa tsa ho phunya, lisebelisoa tsa ho lekanya, likarolo tse sa tsofaleng, li-abrasives tsa tšepe, li-cylinder liners, li-bearing tse nepahetseng, li-nozzle, li-mold tsa tšepe (tse kang li-dies tsa ho hula terata, li-dies tsa bolt, li-dies tsa linate, le li-mold tse fapaneng tsa fastener, ts'ebetso e ntle ea carbide e samentetsoeng butle-butle e ile ea nkela li-mold tsa tšepe tse fetileng sebaka).

Hamorao, carbide e koahetsoeng ka samente le yona e ile ya tswa. Ka 1969, Sweden e ile ya atleha ho hlahisa sesebediswa se koahetsoeng ka titanium carbide. Motheo wa sesebediswa ke tungsten-titanium-cobalt carbide kapa tungsten-cobalt carbide. Botenya ba seaparo sa titanium carbide hodima metsi ke di-micron tse mmalwa feela, empa ha di bapiswa le mofuta o tshwanang wa disebediswa tsa alloy, Bophelo ba tshebeletso bo atoloswa ka makgetlo a 3, mme lebelo la ho seha le eketswa ka 25% ho isa ho 50%. Dilemong tsa bo-1970, moloko wa bone wa disebediswa tse koahetsoeng o ile wa hlaha bakeng sa ho seha disebediswa tse thata ho sebediswa ka mochini.

Carbide e sintered ka samente e siloa joang?

Carbide e samentetsoeng ke thepa ea tšepe e entsoeng ka tšepe ea phofo ea carbide le litšepe tse tlamang tsa tšepe e le 'ngoe kapa tse ngata tse hanyetsang.

Mlinaha tse hlahisang lihlahisoa tse ling

Ho na le linaha tse fetang 50 lefatšeng tse hlahisang carbide e samenteng, ka kakaretso ea tlhahiso ea 27,000-28,000t-. Bahlahisi ba ka sehloohong ke United States, Russia, Sweden, China, Jeremane, Japane, United Kingdom, Fora, jj. 'Maraka oa carbide e samenteng lefatšeng ka bophara o tletse haholo. , tlholisano ea 'maraka e matla haholo. Indasteri ea carbide e samenteng ea Chaena e qalile ho hlaha bofelong ba lilemo tsa bo-1950. Ho tloha lilemong tsa bo-1960 ho isa ho bo-1970, indasteri ea carbide e samenteng ea Chaena e ile ea hola ka potlako. Mathoasong a bo-1990, bokhoni bohle ba tlhahiso ea carbide e samenteng ea Chaena bo fihlile ho 6000t, 'me kakaretso ea tlhahiso ea carbide e samenteng e fihlile ho 5000t, ea bobeli feela ho Russia le United States, e maemong a boraro lefatšeng.

Sehahi sa WC

①Tungsten le cobalt carbide e tšetsoeng ka samente

Likarolo tse ka sehloohong ke tungsten carbide (WC) le binder cobalt (Co).

Sehlopha sa yona se bopilwe ka “YG” (“hard and cobalt” ka Sechaena Pinyin) le peresente ya dikahare tse tloaelehileng tsa cobalt.

Mohlala, YG8 e bolela karolelano ea WCo=8%, 'me karolo e setseng ke tungsten-cobalt carbide ea tungsten carbide.

Lithipa tsa TIC

②Carbide ea Tungsten-titanium-cobalt

Likarolo tse ka sehloohong ke tungsten carbide, titanium carbide (TiC) le cobalt.

Sehlopha sa yona se bopilwe ka “YT” (“thata, titanium” ditlhaku tse pedi ka sehlohlolong sa Pinyin sa Sechaena) le dikahare tse mahareng tsa titanium carbide.

Mohlala, YT15 e bolela karolelano ea WTi=15%, 'me karolo e setseng ke tungsten carbide le tungsten-titanium-cobalt carbide e nang le cobalt.

Sesebelisoa sa Tungsten Titanium Tantalum

③Carbide e entsoeng ka samente ea Tungsten-titanium-tantalum (niobium)

Likarolo tse ka sehloohong ke tungsten carbide, titanium carbide, tantalum carbide (kapa niobium carbide) le cobalt. Mofuta ona oa carbide e samentetsoeng o boetse o bitsoa general cemented carbide kapa universal cemented carbide.

Sehlopha sa yona se bopilwe ka “YW” (sehlongwapele sa fonetiki sa Sechaena sa “hard” le “wan”) hammoho le nomoro ya tatellano, jwalo ka YW1.

Litšobotsi tsa ts'ebetso

Li-Insert tsa Carbide Welded

Ho thatafala ho hoholo (86 ~93HRA, ho lekana le 69 ~81HRC);

Ho thatafala ha mocheso hantle (ho fihlela ho 900 ~1000 ℃, boloka 60HRC);

Ho hanyetsa ho kgohlopa ho hotle.

Lisebelisoa tsa ho seha lik'habohaedreite li potlakile ka makhetlo a 4 ho isa ho a 7 ho feta tšepe e lebelo le phahameng, 'me bophelo ba sesebelisoa bo phahame ka makhetlo a 5 ho isa ho a 80. Ha ho etsoa liforomo le lisebelisoa tsa ho lekanya, bophelo ba tšebeletso bo phahame ka makhetlo a 20 ho isa ho a 150 ho feta ba tšepe ea lisebelisoa tsa alloy. E ka seha thepa e thata ea hoo e ka bang 50HRC.

Leha ho le jwalo, carbide e samentetsweng e a pshatleha habonolo mme e ke ke ya etswa ka mochini, mme ho thata ho etsa disebediswa tse kopaneng tse nang le dibopeho tse rarahaneng. Ka hona, hangata ho etswa mahare a dibopeho tse fapaneng, a kentsweng mmeleng wa disebediswa kapa mmeleng wa hlobo ka ho tjheseletsa, ho kopanya, ho tiisa ka mechine, jj.

Bara e bōpehileng joaloka e khethehileng

Ho sila

Ho bopa sekontiri sa khabide e samenteng ke ho hatella phofo ka har'a billet, ebe o kena ka ontong ea sekontiri ho futhumatsa mocheso o itseng (mocheso o sintering), ho e boloka nako e itseng (nako e itseng), ebe o e pholisa ho fumana thepa ea khabide e samenteng e nang le thepa e hlokahalang.

Ts'ebetso ea ho sila carbide e entsoeng ka samente e ka aroloa ka mekhahlelo e mene ea motheo:

1: Mokhahlelong oa ho tlosa moemeli ea etsang le ho sefa pele ho ho sefa, 'mele o sintered o fetoha ka tsela e latelang:

Ho tlosoa ha sesebelisoa sa ho bopa, ka keketseho ea mocheso mohatong oa pele oa ho sila, sesebelisoa sa ho bopa sea bola kapa se fetoha mouoane butle-butle, 'me' mele o silafetseng oa tlosoa. Mofuta, bongata le ts'ebetso ea ho sila lia fapana.

Di-oxide tse hodima phofo di a fokotseha. Mochesong wa ho sintering, haedrojene e ka fokotsa di-oxide tsa cobalt le tungsten. Haeba ntho e etsang e tloswa ka vacuum mme e sintered, karabelo ya carbon-oxygen ha e matla. Kgatello ya ho kopana pakeng tsa dikarolwana tsa phofo e fediswa butle-butle, phofo ya tshepe e tlamahaneng e qala ho fola le ho boela e fetoha, ho hasana ha bokahodimo ho qala ho etsahala, mme matla a briquetting a ntlafala.

2: Mokhahlelo o tiileng oa ho sila mocheso (mocheso oa 800℃–eutectic)

Mochesong pele ho ponahalo ea mokhahlelo oa metsi, ho phaella ho tsoeleng pele ts'ebetso ea mohato o fetileng, karabelo ea mokhahlelo o tiileng le ho hasana lia matlafala, phallo ea polasetiki ea ntlafala, 'me' mele o sintered o fokotseha haholo.

3: Mokhahlelo oa ho sila ha mokhahlelo oa metsi (mocheso oa eutectic - mocheso oa ho sila)

Ha karolo ea mokelikeli e hlaha 'meleng o sintered, ho fokotseha ho phethoa kapele, ho lateloa ke phetoho ea kristale ho theha sebopeho sa motheo le sebopeho sa motsoako.

4: Mokhahlelo oa ho pholisa (mocheso oa ho chesa - mocheso oa kamore)

Mothating ona, sebopeho le sebopeho sa motswako wa alloy di na le diphetoho tse itseng maemong a fapaneng a ho phodisa. Tšobotsi ena e ka sebediswa ho futhumatsa carbide e kentsweng ka samente ho ntlafatsa thepa ya yona ya mmele le ya metjhini.

Nako ea poso: Mmesa-11-2022