Mokgweng wa tlhahiso ya disebediswa tsa ho seha dikharbide bakeng sa ho seha difaeba tsa dikhemikhale (tse sebediswang bakeng sa ho seha thepa e kang nylon, polyester, le carbon fiber), tshebetso ena e rarahane, e kenyeletsa mehato e mengata ya bohlokwa ho kenyeletswa le kgetho ya thepa, ho bopa, ho sinter le ho sebetsana le moedi. Mohato ka mong o ka hlahisa diphephetso tsa botekgeniki. Ka tlase ke Diphephetso tse tlwaelehileng tsa mantlha tse kopaneng nakong ya tshebetso ya tlhahiso le ditharollo tsa tsona.

I. Liphephetso Mokhahlelong oa ho Lokisetsa Lintho tse Bonahalang

1. Ho se Tšoane ha Phofo ea WC-Co

Bothata e ka ba:

Ho kopanya phofo ea carbide e sa koaheloang ka samente (WC-Co) ka tsela e sa lekanang ho baka karohano ea metsoako ka mor'a ho chesa, e leng se behang tekano ea ho tiea le ho tiea kotsing.

Litharollo bakeng sa hau:

Ntlafatsa ho tšoana ha phofo ka ho sila bolo e nang le matla a mangata kapa ho e fafatsa ka spray.

Kenya dithibela kgolo ya dithollo tse sa lateleng (mohlala, Cr₃C₂, VC) ho laola boholo ba dithollo tsa WC (0.5–1 μm).

2. Kabo e sa Lekaneng ea Mokhahlelo oa Binder (Co)

Bothata e ka ba:

Ho kopana ha likarolo tse peli ho etsa "matamo a cobalt," ho fokotsa ho hanyetsa tšusumetso le ho baka ho taboha ha mathoko nakong ea ho seha ha faeba.

Seo re ka se etsang:

Sebelisa phofo ea nano-cobalt (<100 nm) ka ho sila ka metsi ho ntlafatsa ho hasana.

Fetola maemo a mocheso oa sintering (boloka 1400–1450°C nakong ea sintering ea mokelikeli).

II. Mathata a Ts'ebetso ea ho Theha le ho Sila

1. Liphoso ho Thehoeng ha Khatiso

Bothata e ka ba:

Ho se tšoane ha bongata ba 'mele nakong ea ho hatella ka mokhoa o batang (CIP) kapa ho hatella ka mokhoa o batang ho baka mapetso/ho arola 'mele e tala.

Litharollo bakeng sa hau:

Ntlafatsa kgatello ya ho tobetsa (200–300 MPa) le nako ya ho dula.

Amohela ho tobetsa ka mahlakoreng a mabeli kapa ho etsa moetso oa tšepe (MIM) bakeng sa li-geometri tse rarahaneng.

2. Ho Fetoha ha Sintering le ho se Tsitse ha Dimensional

Bothata e ka ba:

Ho fokotseha ho sa tsitsang ha sintering (hangata 15-20%) ho lebisa ho diphetoho tse feteletseng tsa geometry ya mathoko (mohlala, radius ya mathoko >10 μm).

Mekhoa ea Taolo:

Sebelisa di-mold tsa graphite + Al₂O₃ spacers ho fokotsa ho feto-fetoha ha mocheso o phahameng.

Kenya spark plasma sintering (SPS) ho fokotsa nako ea sintering le porosity (<0.5%).

III. Liphephetso tsa ho sebetsana le ho koahela le ho lokisa mahlakore

1. Mathata a ho Sila a Moeli o Nepahetseng ka ho Fetisisa

Bothata e ka ba:

Ho fihlella mathoko a bohale (radius ea mathoko <5 μm) ho sitisoa ke ho thatafala ho hoholo (HRA ≥90), ho bakang katleho e tlase ea ho sila le ho senyeha ha mabili ka potlako.

Ntlafatso ea Ts'ebetso:

Sebelisa mabili a taemane (boholo ba grit W10–W20) ka electrolytic in-process dressing (ELID).

Amohela ho sila ka thuso ea laser (LAG) ho fokotsa matla a ho sila le ho ntlafatsa ho teteana ha bokaholimo (Ra ≤0.1 μm).

2. Ho khomarela ho sa lekaneng ha seaparo

Bothata e ka ba:

Liaparo tsa TiAlN/DLC lia taboha nakong ea ho seha ka lebelo le phahameng likhoele tsa maiketsetso (haholo-holo likhoele tsa carbon tse thehiloeng ho resin).

Maano a Ntlafatso:

Pele ho kalafo: Ho hlwekisa ka dibomo tsa Ar⁺ ion + Cr interlayer (botenya ba 0.2–0.5 μm).

Fetohela ho lipente tsa gradient tse nang le mekhahlelo e mengata (mohlala, TiCN/AlTiO₃), ho ntlafatsa ho khomarela ka >30%.

Mabapi le Huaxin: Moetsi oa Lithipa tsa ho Senya tsa Tungsten Carbide tse samentetsoeng

CHENGDU HUAXIN SAMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oa lihlahisoa tsa carbide tsa tungsten, tse kang lithipa tsa carbide tse kenngoang bakeng sa ho betla lehong, lithipa tse chitja tsa carbide bakeng sa ho seha lithupa tsa sefe ea koae le sakerete, lithipa tse chitja bakeng sa ho seha khateboto e nang le corugat, mahare a lehare a masoba a mararo/mahare a nang le masoba bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya Amerika A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Ikopanye le rona kajeno 'me u tla natefeloa ke melemo ea boleng bo botle le lits'ebeletso tse tsoang lihlahisoa tsa rona!

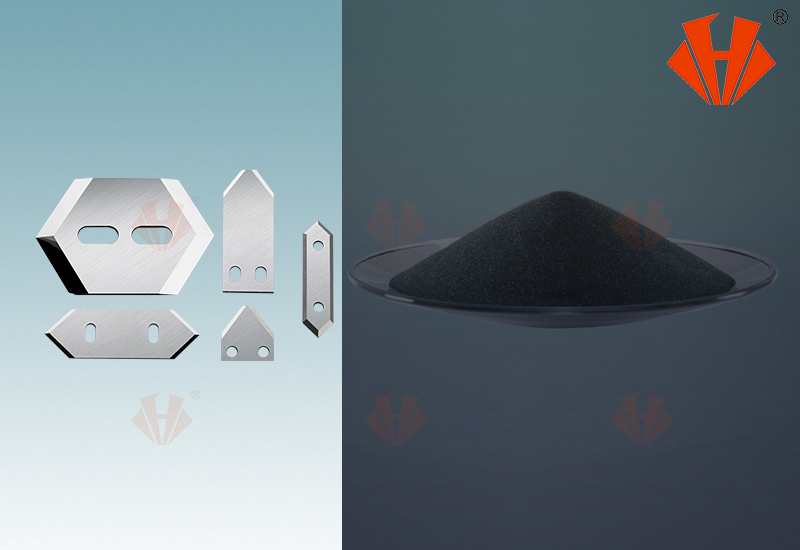

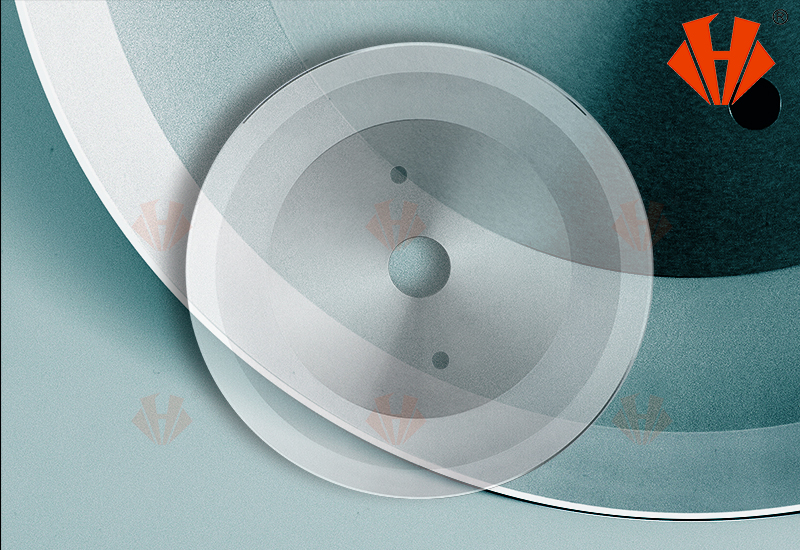

Lihlahisoa tsa li-blade tsa indasteri tsa tungsten carbide tse sebetsang hantle haholo

Tšebeletso e Ikhethileng

Huaxin Cemented Carbide e etsa di-blade tsa tungsten carbide tse ikgethileng, di-blank tse fetotsweng tse tloaelehileng le tse tloaelehileng le di-preform, ho qala ka phofo ho isa di-blank tse fedisitsweng. Kgetho ya rona e felletseng ya dikereiti le tshebetso ya rona ya tlhahiso e fana ka disebediswa tse sebetsang hantle, tse tshepahalang tse bopehileng jwalo ka netweke tse sebetsanang le diphephetso tse ikgethang tsa tshebediso ya bareki diindastering tse fapaneng.

Litharollo tse Loketseng Indasteri e 'Ngoe le e 'Ngoe

mahare a entsoeng ka mokhoa o ikhethileng

Moetsi ea ka sehloohong oa mahare a indasteri

Lipotso tse tloaelehileng tsa bareki le likarabo tsa Huaxin

Seo se itshetlehile ka bongata, hangata matsatsi a 5-14. Jwalo ka moetsi wa di-blades tsa indasteri, Huaxin Cement Carbide e rera tlhahiso ka diotara le dikopo tsa bareki.

Hangata dibeke tse 3-6, haeba o kopa dithipa tsa mochini tse ikgethileng kapa di-blade tsa indasteri tse seng teng nakong ya ho reka. Fumana Maemo a ho Reka le ho Romela a Sollex mona.

Haeba o kopa lithipa tsa mochini tse etselitsoeng uena kapa mahare a indasteri a seng teng nakong ea theko. Fumana Sollex Theko le Maemo a PhanoMona.

Hangata T/T, Western Union...di-depositi pele, Diodara tsohle tsa pele ho bareki ba batjha di lefellwa pele ho nako. Diodara tse ding di ka lefshwa ka invoice...iteanye le ronaho tseba haholoanyane

E, ikopanye le rona, lithipa tsa indasteri li fumaneha ka mefuta e fapaneng, ho kenyeletsoa lithipa tse chitja tse ka holimo, tse chitja tse ka tlase, lithipa tse nang le meno a sekoti/a meno, lithipa tse chitja tse phunyeletsang, lithipa tse otlolohileng, lithipa tsa guillotine, lithipa tse nchocho tse ka holimo, lithipa tse nang le lehare le mahlakore a mane le mahlakore a trapezoidal.

Ho u thusa ho fumana lehare le letle ka ho fetisisa, Huaxin Cement Carbide e ka u fa mehlala e 'maloa ea mahare a ho leka tlhahiso. Bakeng sa ho seha le ho fetola thepa e tenyetsehang joalo ka filimi ea polasetiki, foil, vinyl, pampiri le tse ling, re fana ka mahare a ho fetola ho kenyeletsoa le mahare a nang le masoba le mahare a nang le masoba a mararo. Re romelle potso haeba u thahasella mahare a mochini, 'me re tla u fa nyehelo. Mehlala ea lithipa tse entsoeng ka mokhoa o ikhethileng ha e fumanehe empa u amohelehile haholo ho odara palo e tlase ea odara.

Ho na le mekhoa e mengata e tla lelefatsa nako e telele le bophelo ba shelefo ea lithipa tsa hau tsa indasteri le mahare a teng setokong. Ikopanye le rona ho tseba hore na ho paka lithipa tsa mochini hantle, maemo a polokelo, mongobo le mocheso oa moea, le lipente tse ling li tla sireletsa lithipa tsa hau joang le ho boloka ts'ebetso ea tsona ea ho seha.

Nako ea poso: Phato-15-2025