Mahare a Sehang Pampiri

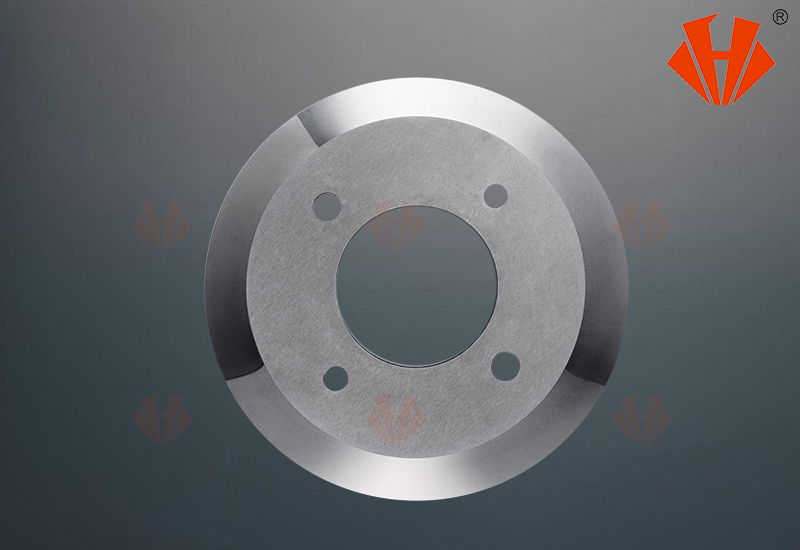

Li-blades tsa mochini oa ho itšeha o chitja oa pampiri ea mantlha

Mahare a fetolelang pampiri, a entsweng ka ho khetheha bakeng sa mesebetsi ya ho seha ka nepo ditsamaisong tsa tlhahiso ya diphaephe tsa pampiri, a sebetsa e le dikarolo tsa bohlokwa ka hara mechini ya ho sebetsana le pampiri ya indasteri.

Lisebelisoa tsena tse khethehileng tsa ho seha li entsoe ka thepa e sebetsang hantle - ho kenyeletsoa metsoako ea tungsten carbide, litšepe tsa boleng ba lisebelisoa, le mekhoa e tsoetseng pele ea ceramic - ka khetho ea thepa e khethoang ke liparamente tse itseng tsa ts'ebetso tse kang botenya ba substrate, litlhoko tsa lebelo la ho seha, le maemo a ho tšoarella ha potoloho ea tlhahiso lits'ebetsong tsa phetoho ea pampiri.

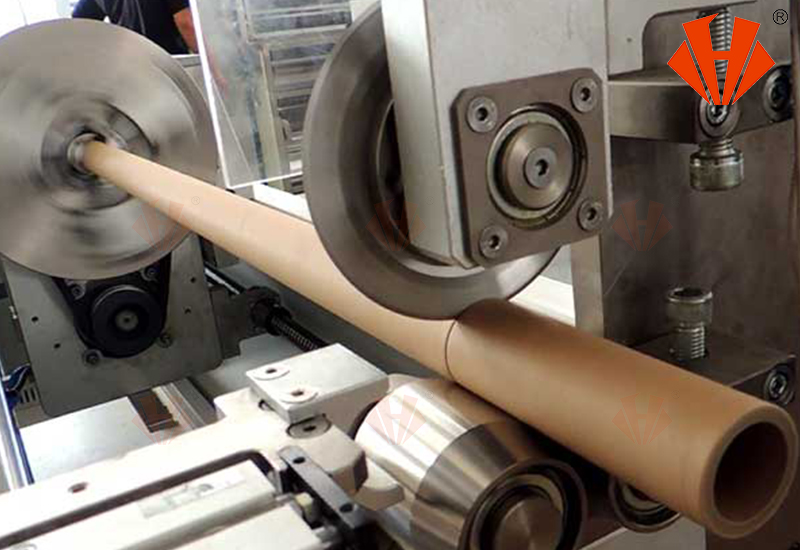

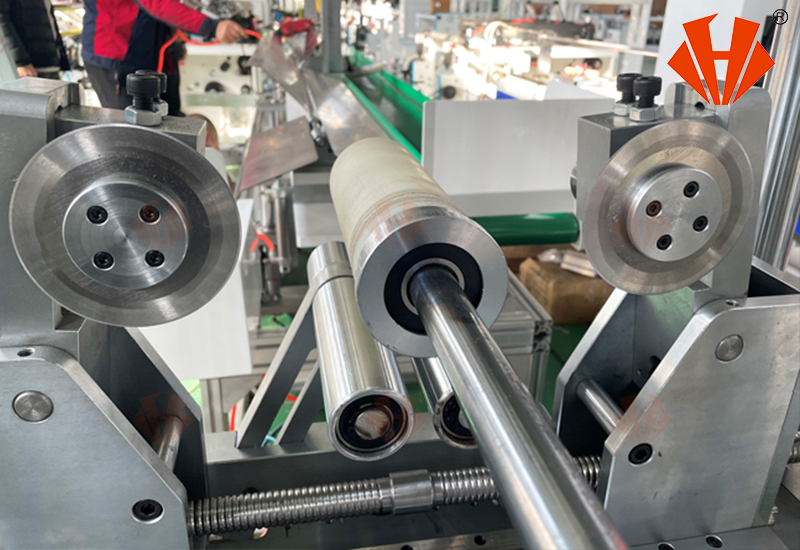

Selelekela sa Li-blades tsa Mochini oa ho Seha oa Core ea Pampiri

Melemo:

Bokaholimo ba mahare ana bo etselitsoe ho ba bohale ka mokhoa o ikhethang, bo boreleli, le ho tšoarella. Ka ho sebelisa lisebelisoa tse tsoetseng pele tsa ho sebetsana le ho nepahala tse tsoang kantle ho naha, mahare ana a fihlella boleng bo holimo ba bohale le ho nepahala ha boholo. Bokhoni bona bo atolohela ho hlahiseng mahare a tloaelehileng a ho seha lirolo le Mahare a Score Slitter, hammoho le mahare a sa tloaelehang a fetolelang pampiri a etselitsoeng uena, a etselitsoeng ho fihlela litlhaloso tse ikhethang tsa bareki.

E 'ngoe ea litšobotsi tse ikhethang tsa mahare ana ke bophelo ba 'ona ba nako e telele ba tšebeletso, bo bakoang ke coefficient e tlase ea khohlano e fokotsang ho tsofala nakong ea ts'ebetso. Lehare ka leng le feta tlhahlobong e matla ea boleng ha le fumana thepa e tala le nakong eohle ea tlhahiso, ho netefatsa ts'ebetso e tsitsitseng le ts'epo. Tiisetso ea ho thatafala e fihlelleha ka kalafo e rarahaneng ea mocheso le ts'ebetso ea vacuum ea thepa e tala, e leng se fellang ka mahare a nang le matla a eketsehileng le mamello.

Li-blades tsa ho seha tsa mantlha tsa pampirike tsa bohlokoa tlhahisong ea lipeipi tsa pampiri le li-core, tse sebelisoang haholo liindastering tse kang liphutheloana, masela le khatiso. Ebang ke bakeng sa lits'ebetso tse tloaelehileng tsa indasteri kapa litlhoko tse ikhethileng, mahare ana a ka fetoloa ho latela boholo, boima le sebopeho sa thepa ho lumellana le litlhoko tse itseng tsa mochini.

Li-blades tsa Core Cutterli fana ka motsoako oa ho nepahala, ho tšoarella le ho tenyetseha, e leng se etsang hore li be tsa bohlokoa haholo lefapheng la ho fetolela pampiri. Ka likhetho tse tlohang ho tungsten carbide ho ea ho li-alloy tse khethehileng, le bokhoni ba ho hlahisa litlhophiso tse tloaelehileng le tse seng tsa maemo, mahare ana a fihlela litlhoko tse fapaneng tsa lits'ebetso tsa tlhahiso tsa sejoale-joale ka boleng bo sa bapisoang.