Li-blades tsa seha-faeba tsa lik'hemik'hale tsa Tungsten Carbide

Li-blades tsa lik'hemik'hale tsa faeba (Polyester (PET) Staple Fiber Cutting Blade)

Likaroloana:

Litekanyo: 117.5x15.7x0.884mm-R1.6 74.6x15.7x0.884mm-R1.6

Li-parameter tsa Tekheniki

Lisebelisoa: TUNGSTEN CARBIDE

Sehlopha sa Carbide: E ntle / E ntle haholo

Kopo: Li-blades tsa lik'hemik'hale tsa faeba tse sehang bakeng sa ho seha lik'hemik'hale tse tloaelehileng tsa polypropylene fiber le fiberglass/mask lesela le sa lohiloeng

E loketse mechine e mengata ea masela: Mahare a likhoele tsa Staple bakeng sa Lumus, Barmag, Fleissner, Neumag, Zimmer, DM&E

Kopo

Mahare ana a mesebetsi ea matsoho ea indasteri a sehiloeng ka nepo a sebelisoa ka tsela e latelang:

○ Pampiri

○ Ho seha lesela/felte

○ Ho Seha Filimi ea Mochini oa Liindasteri oa TCT/Ho Seha Maleiri

○ Mochini oa ho Paka Filimi

○ Ho Seha Foile ea Aluminium ea Koporo

○ Ho Seha Pampiri ka Sephutheloana

○ Ho Seha Foam ea Filimi

○ Dienes Slitting

○ Sekotjana sa maske se sa lohiloeng

Litšebeletso:

Moralo / Mokhoa o Ikhethileng / Teko

Sampole / Tlhahiso / Paka / Thomello

Thekiso ea morao

Ke hobane'ng ha Huaxin?

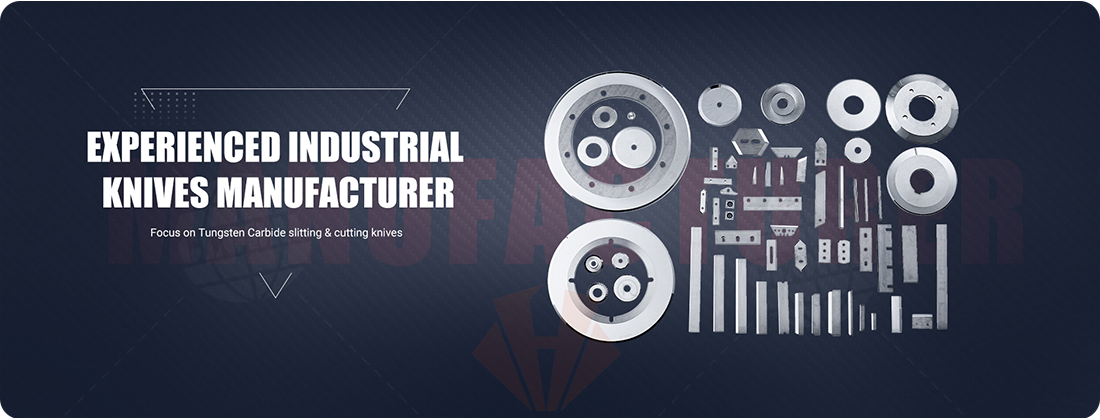

CHENGDU HUAXIN SAMENTED CARBIDE CO., LTD ke mofani oa litsebi le moetsi oa lihlahisoa tsa carbide tsa tungsten, tse kang lithipa tsa carbide tse kenngoang bakeng sa ho betla lehong, lithipa tse chitja tsa carbide bakeng sa ho seha lithupa tsa sefe ea koae le sakerete, lithipa tse chitja bakeng sa ho seha khateboto e nang le corugat, mahare a lehare a masoba a mararo/mahare a nang le masoba bakeng sa ho paka, theipi, ho seha filimi e tšesaane, mahare a faeba bakeng sa indasteri ea masela jj.

Ka ntshetsopele ya dilemo tse fetang 25, dihlahiswa tsa rona di rometswe kantle ho naha ho ya US A, Russia, Amerika Borwa, India, Turkey, Pakistan, Australia, Asia Borwa-bochabela jj. Ka boleng bo botle le ditheko tse hlwahlwa, Boikutlo ba rona ba ho sebetsa ka thata le karabelo di amohetswe ke bareki ba rona. Mme re ka rata ho theha dikamano tse ntjha tsa kgwebo le bareki ba batjha.

Lipotso Tse Botsoang Khafetsa

P1. Na nka fumana odara ea mohlala?

A: E, odara ea mohlala ho leka le ho hlahloba boleng,

Mehlala e tsoakiloeng ea amoheleha.

P2. Na le fana ka disampole? Na ke mahala?

A: E, sampole ea mahala, empa thepa e lokela ho ba lehlakoreng la hau.

P1. Na nka fumana odara ea mohlala?

K: E, odara ea mohlala ho leka le ho hlahloba boleng, Mehlala e tsoakiloeng ea amoheleha.

P2. Na le fana ka disampole? Na ke mahala?

A: E, sampole ea mahala, empa thepa e lokela ho ba lehlakoreng la hau.

P3. Na o na le moedi ofe kapa ofe wa MOQ bakeng sa odara?

A: MOQ e tlase, 10pcs bakeng sa tlhahlobo ea sampole lia fumaneha.

P4. Nako ea hau ea ho tlisa ke efe?

K: Ka kakaretso matsatsi a 2-5 haeba a le teng setokong. kapa matsatsi a 20-30 ho latela moralo oa hau. Nako ea tlhahiso ea bongata ho latela bongata.

P5. Na o ka hlahisa ho latela disampole?

A: E, re ka hlahisa ka disampole tsa hau kapa litšoantšo tsa botekgeniki.

P6. Na o hlahloba thepa yohle ya hao pele o e isa?

A: E, re na le tlhahlobo ea 100% pele re fana ka thepa.

Mahare a indasteri bakeng sa ho seha le ho fetola filimi ea polasetiki, foil, pampiri, thepa e sa lohiloeng, e tenyetsehang.

Lihlahisoa tsa rona ke mahare a sebetsang hantle haholo a nang le mamello e kholo e ntlafalitsoeng bakeng sa ho seha filimi ea polasetiki le foil. Ho latela seo u se batlang, Huaxin e fana ka mahare le mahare a theko e tlase a nang le ts'ebetso e phahameng haholo. U amohelehile ho odara lisampole ho leka mahare a rona.